Inverted-convex overall central drainage ditch device in highway tunnel

A road tunnel, convex-shaped technology, applied in drainage, safety devices, mining equipment and other directions, can solve problems such as affecting the safety of tunnel operation, restricting progress, uneven tunnel settlement, etc., to achieve reliable fixation and flexibility, and ensure stability. performance and durability, easy-to-achieve effects of control means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

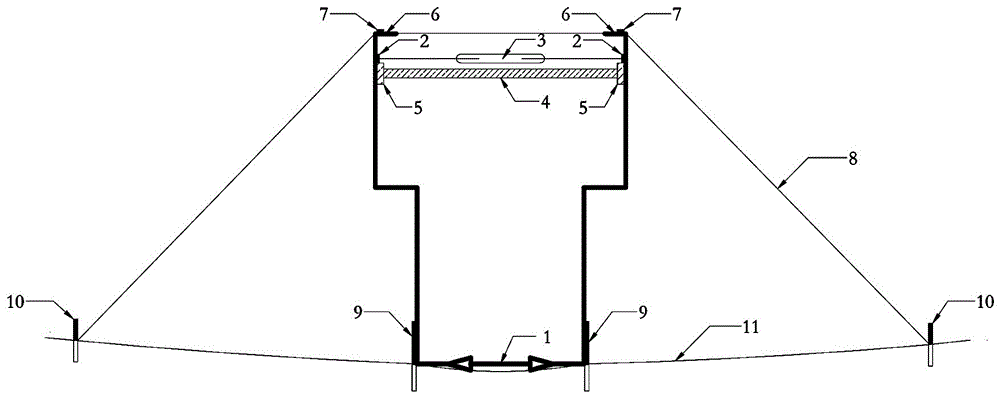

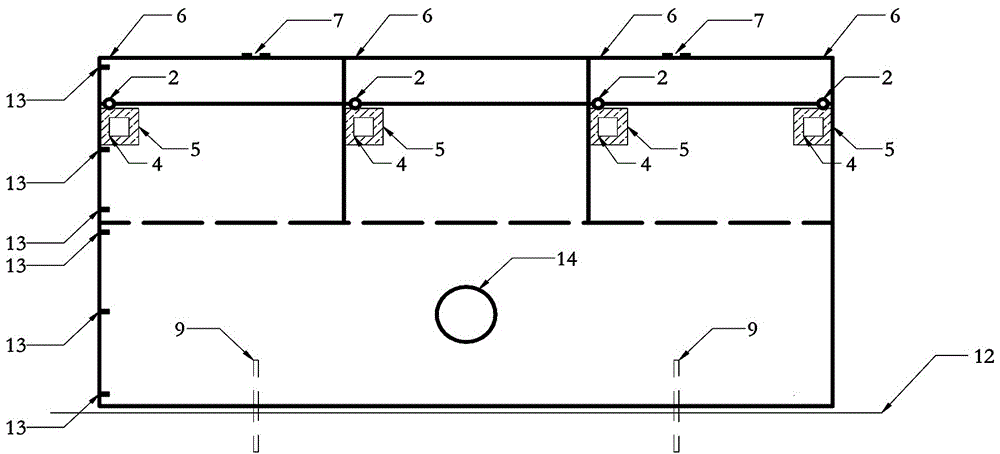

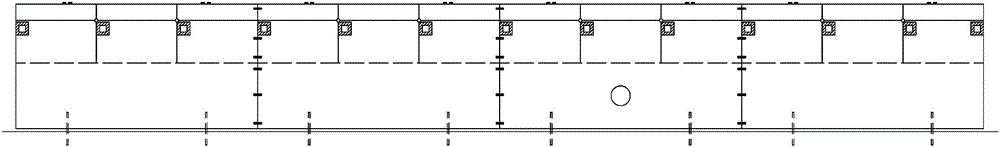

[0036] The entire tunnel drainage ditch needs several formwork devices such as image 3 The bolt connection structure shown in the figure realizes rapid and standardized construction, and the inverted arch filling (including vertical and horizontal drainage blind pipe burial) and the center ditch are combined for construction. With the device, each circular inverted arch can form a central ditch of the same length after being filled.

[0037] The overall drainage ditch formwork device is 6m long in longitudinal direction, and is assembled and connected by 4 "convex"-shaped devices with a length of 1.5m, which is convenient for installation, disassembly and removal.

[0038] The structure of the integral drainage di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com