Oil well production increasing environment-friendly device

An environmental protection device and oil well technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., to achieve good connection effect, increase oil pumping space, and improve storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

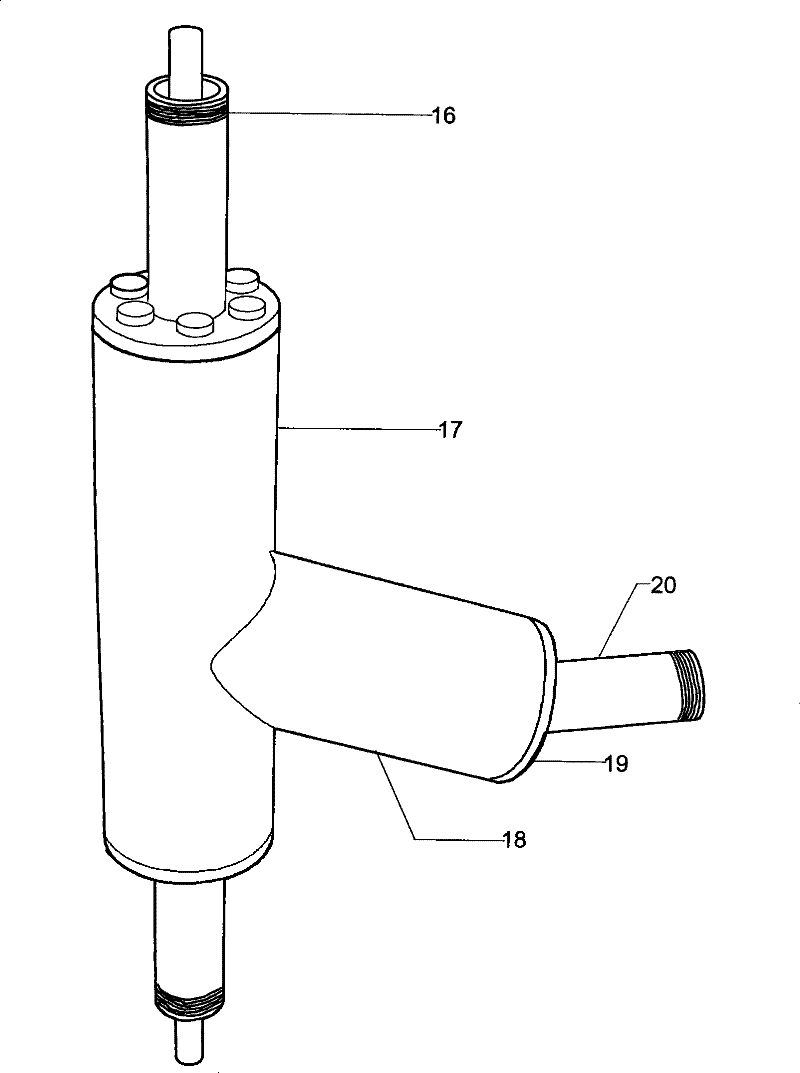

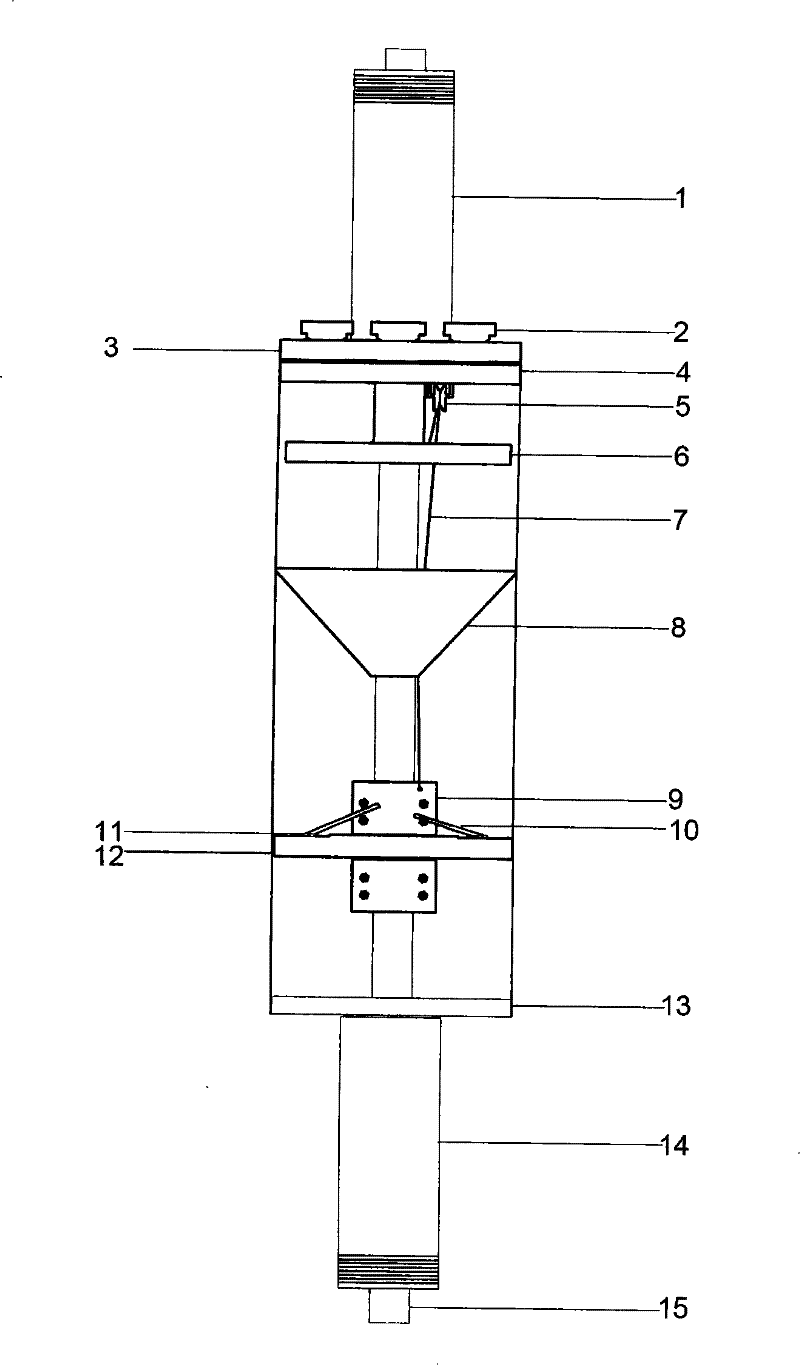

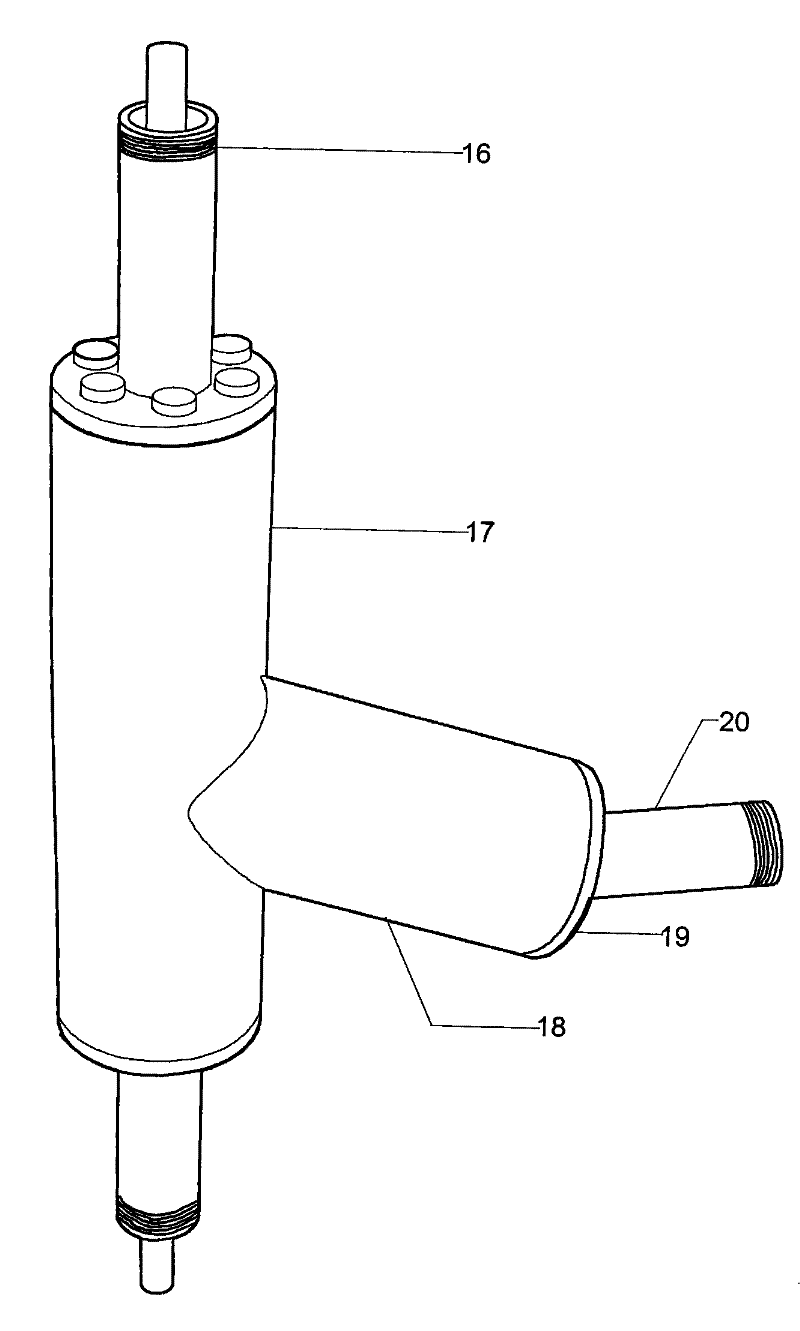

[0010] figure 1 , 2 Specific embodiments of the invention are given.

[0011] An oil well stimulation environmental protection device, which has a lower casing 14 connected with oil well tubing and an upper casing 1 connected with a pumping unit, an outer casing 17 is connected between the upper casing 1 and the lower casing 14, and the outer casing The inner diameter of 17 is 2-3 times the inner diameter of the upper casing 1 and the lower casing 14; the upper casing 1 and the outer casing 17 are sealed and connected through flanges 3 and 4; the middle part of the outer casing 17 is connected with an oil storage pipe 18, and the outlet of the oil storage pipe 18 Connect the oil outlet pipe interface 20 on the top. In the outer casing 17, there is a check valve mechanism that reciprocates up and down with the sucker rod of the pumping unit. The one-way valve mechanism includes a flange 12, the flange 12 is installed on the sucker rod through the clip 9, and there is an oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com