Open type water-sealed valve chamber of dry type blast furnace gas holder

An open technology for gas cabinets, applied in the field of open water-sealed valve chambers, can solve problems such as life-threatening safety, gas poisoning of operators, and non-manual contact automatic drainage, etc., and achieve the effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

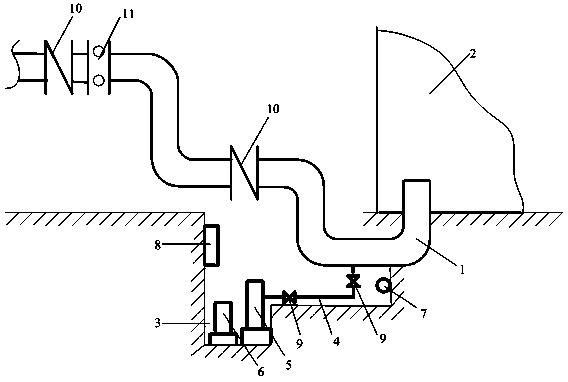

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0018] It can be seen from the accompanying drawings that the open water-sealed valve chamber of the dry-type blast furnace gas cabinet of this scheme includes a U-shaped gas channel 1 communicating with the blast furnace gas cabinet 2, and a water collection tank is arranged below the U-shaped gas channel 1 3. One end of a conveying pipe 4 communicates with the bottom of the U-shaped gas channel 1, and the other end of the conveying pipe 4 communicates with a drainer 5. The drainer 5 is arranged in the sump 3, and the drainer 5 is arranged in the sump. 3 is also provided with a sewage pump 6, a valve 9 is provided on the delivery pipe 4, and a CO sound and light alarm 7 is provided on the U-shaped gas channel 11.

[0019] One side of the U-shaped gas passage 1 is provided with an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com