An Optimal Design Method for Furnace Pressure Control of Regenerative Industrial Heating Furnace

A furnace pressure control and optimization design technology, which is applied to furnace control devices, lighting and heating equipment, furnaces, etc., can solve the problem of unstable time interval between furnace discharge and furnace slab loading, large influence of furnace pressure fluctuations, flue gate Frequent movement and other problems, to improve the combustion control effect, reduce hardware investment, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

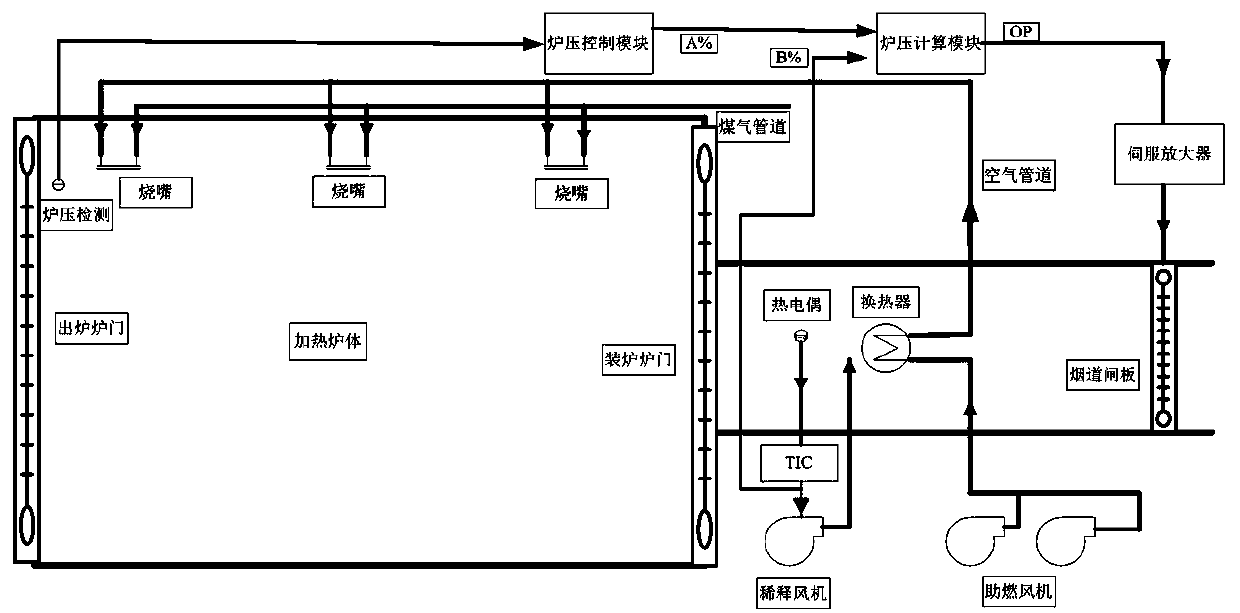

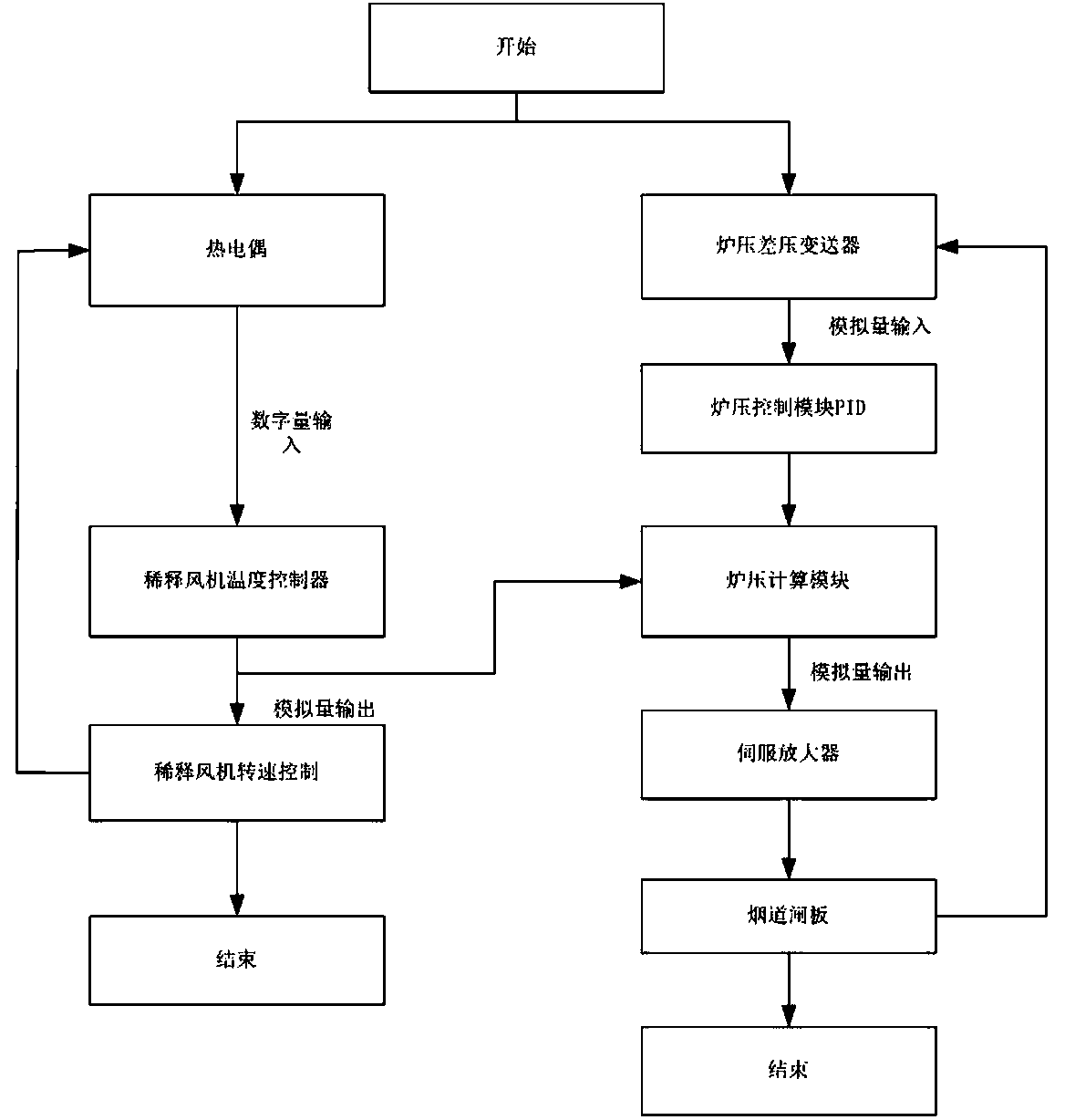

[0028] In this embodiment, the main purpose is to find an optimized furnace pressure control method, which can keep the furnace pressure stable within a certain range under the frequent opening and closing of the furnace door and the disturbance of interference signals. The specific method is to fully analyze the interference factors that cause furnace pressure fluctuations in the furnace pressure control, find out the main interference factors, and implement control on the main interference factors, so as to eliminate the interference signals that cause furnace pressure fluctuations in the bud. , at the same time reduce the proportion of the furnace pressure fluctuation signal in the control, so that the flue gate action signal not only takes into account the fluctuation of the furnace pressure detection signal, but also takes into account the fluctuati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com