Double cutting feed rotating seal main shaft of honing machine

A rotary seal, honing machine technology, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure, oil leakage, inconvenient processing, manufacturing, assembly and use, etc., to achieve simple structure and solve oil leakage. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

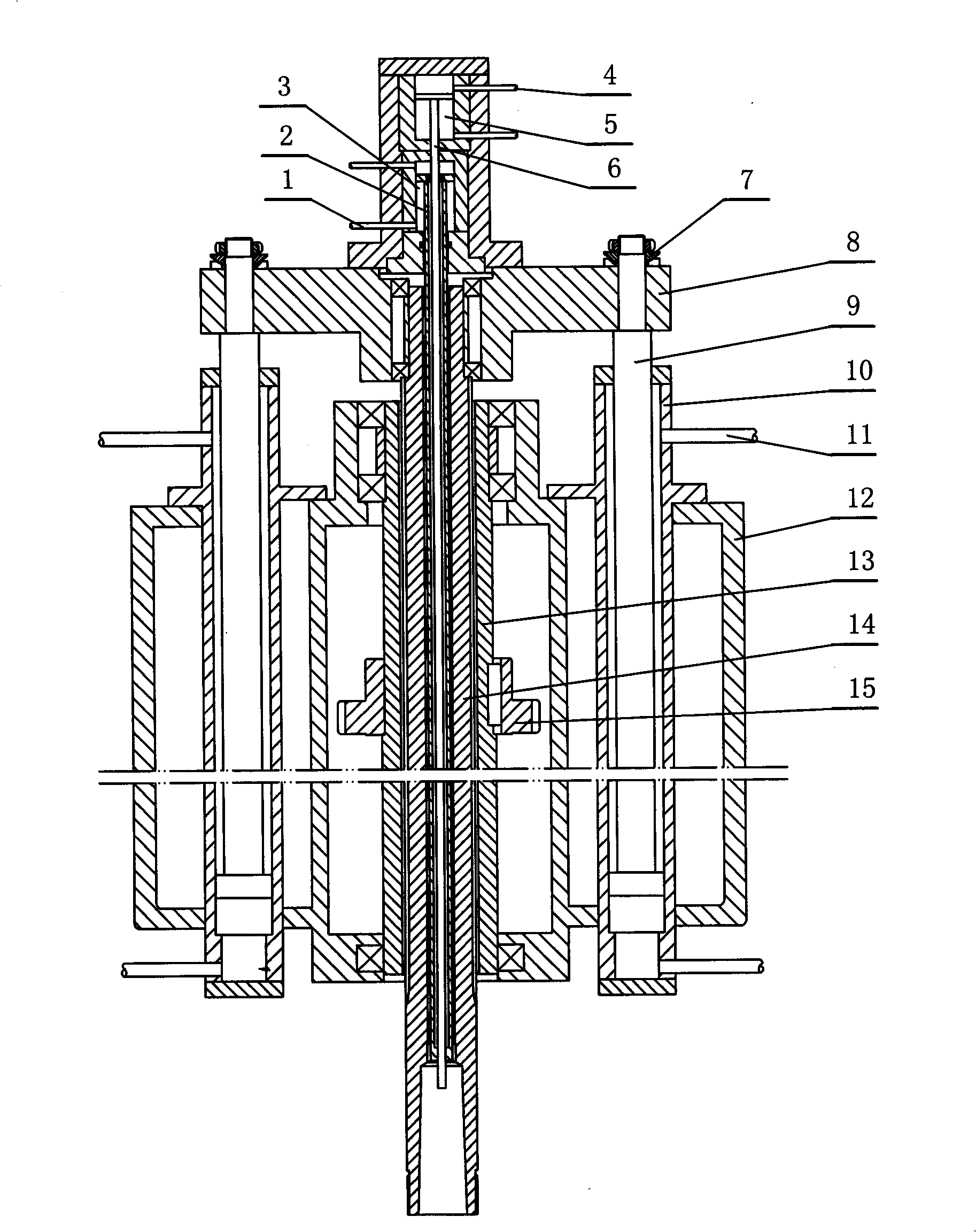

[0008] Such as figure 1 In the double-feed rotary sealed spindle device of the honing machine shown, the spindle 14 is a hollow shaft, and a spindle sleeve 13 is sleeved outside the spindle through a spline connection, and a spindle gear 15 meshing with the internal gear of the spindle box is fixed on the spindle sleeve. The rotation is driven by the main shaft box, the main shaft gear and the main shaft sleeve. The upper and lower ends of the main shaft sleeve are fixed and positioned by bearings installed on the main shaft box, and the upper end of the main shaft is fixed on the support 8 by bearings. Rough honing feed oil cylinder 3 and fine honing feed oil cylinder 5 are installed on the support, and the centers of the above two oil cylinders coincide with the center of the main shaft. The fine honing ejector 6 in the fine honing feed cylinder 5 at the upper end is set in the rough honing hollow ejector 2 of the rough honing feed cylinder at the lower end of the fine honi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com