Turbocharger

A turbocharger and turbine technology, which is applied in the directions of machines/engines, engine components, internal combustion piston engines, etc., can solve the problems of oil leakage at the compressor end of the turbocharger and large negative pressure at the wheel back. The effect of preventing oil leakage, reducing negative pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

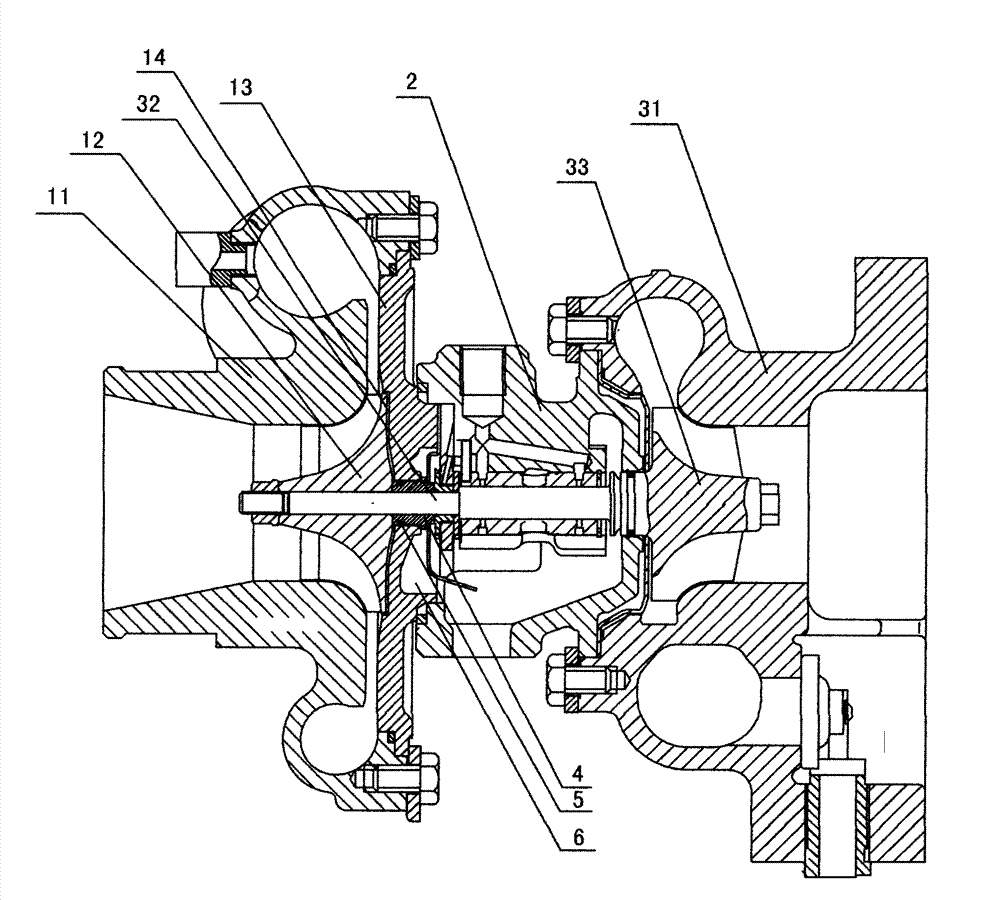

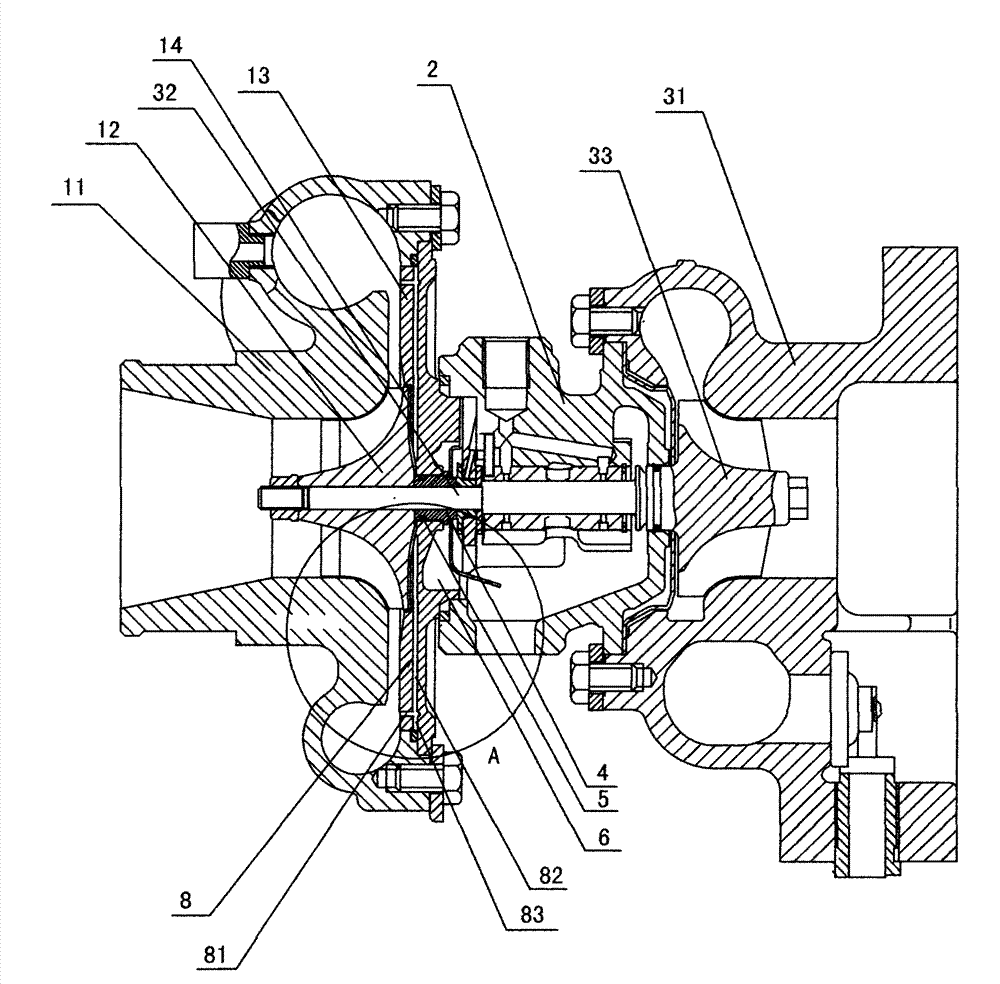

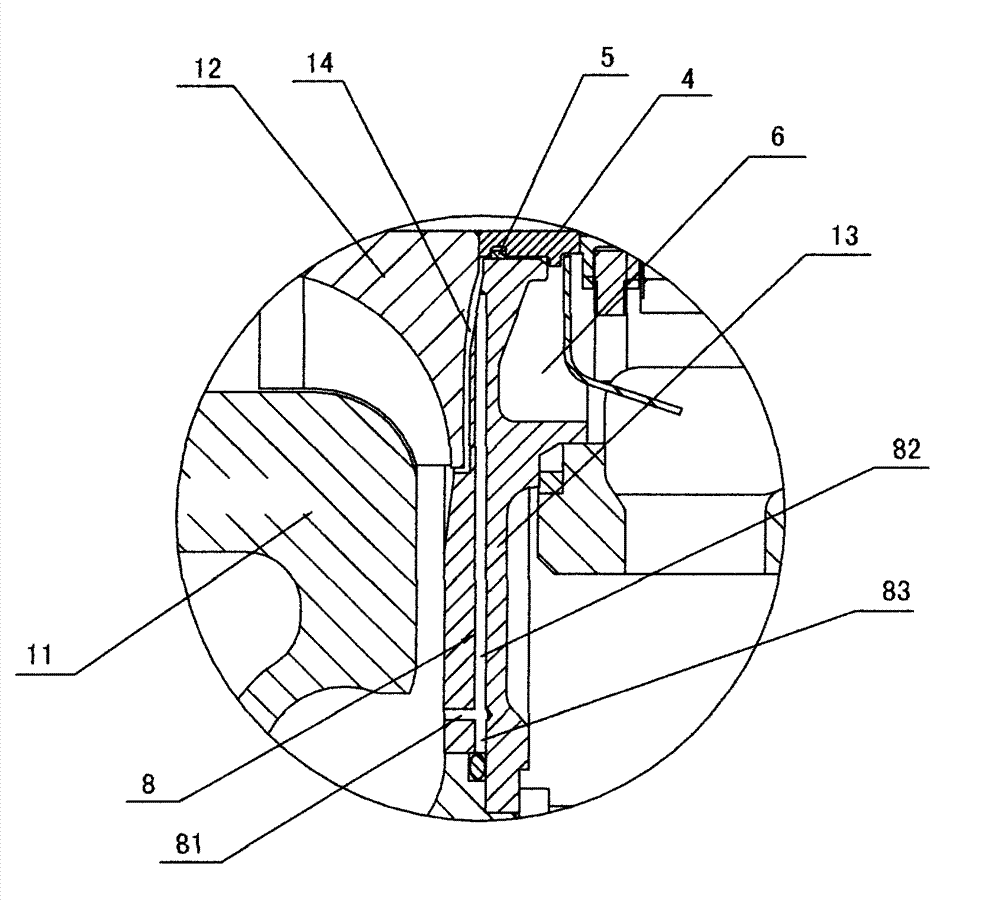

[0022] A kind of turbocharger that the present invention proposes, as figure 2 and image 3 As shown, it includes a compressor casing 11, an intermediate body 2 and a turbine casing 31 connected together, a turbine shaft 32 is installed in rotation in the intermediate body 2, and a compressor impeller 12 is fixed on one end of the turbine shaft 32, and the compressor impeller 12 is set In the compressor casing 11, the compressor wheel 12 and the compressor casing 11 constitute a centrifugal compressor, the other end of the turbine shaft 32 is fixed with a turbine 33, the turbine 33 is arranged in the turbine casing 31, and the shaft seal 4 is set on the turbine shaft 32 , one shaft end of the shaft seal sleeve 4 is in contact with the wheel back of the compressor impeller 12, the shaft seal sleeve 4 is covered with a compressor back plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com