Extractor hood and oil cup thereof

A range hood and oil cup technology applied in the field of kitchen appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

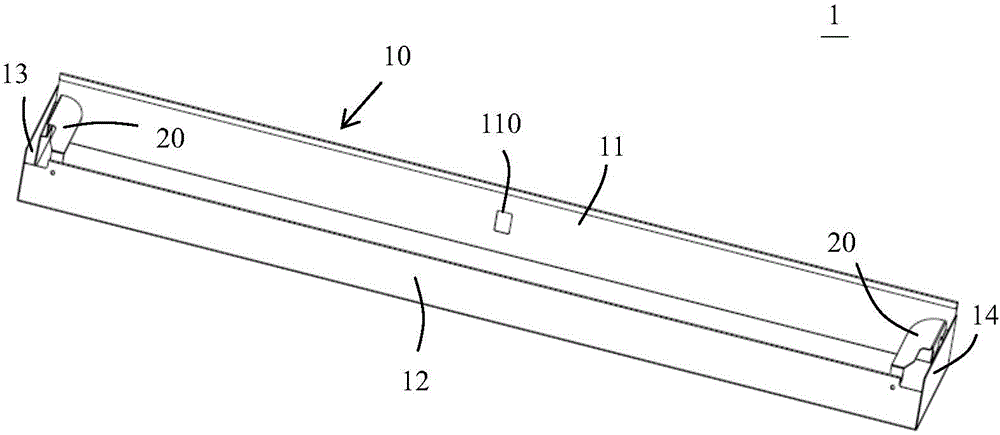

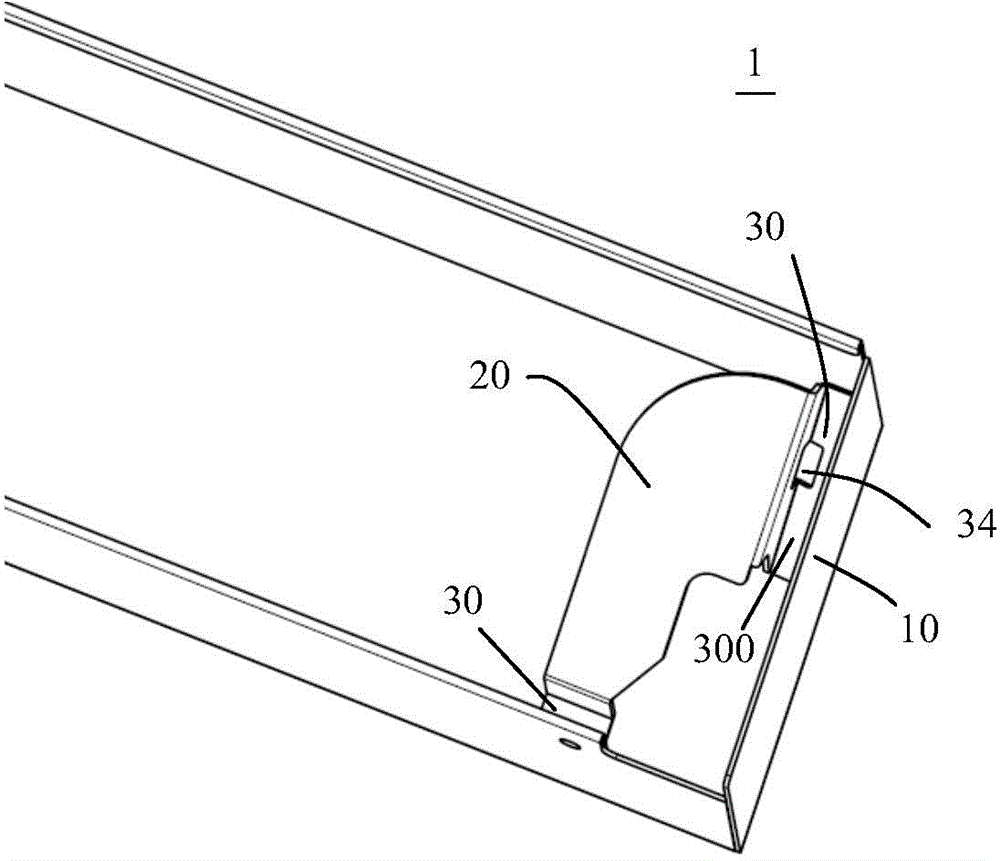

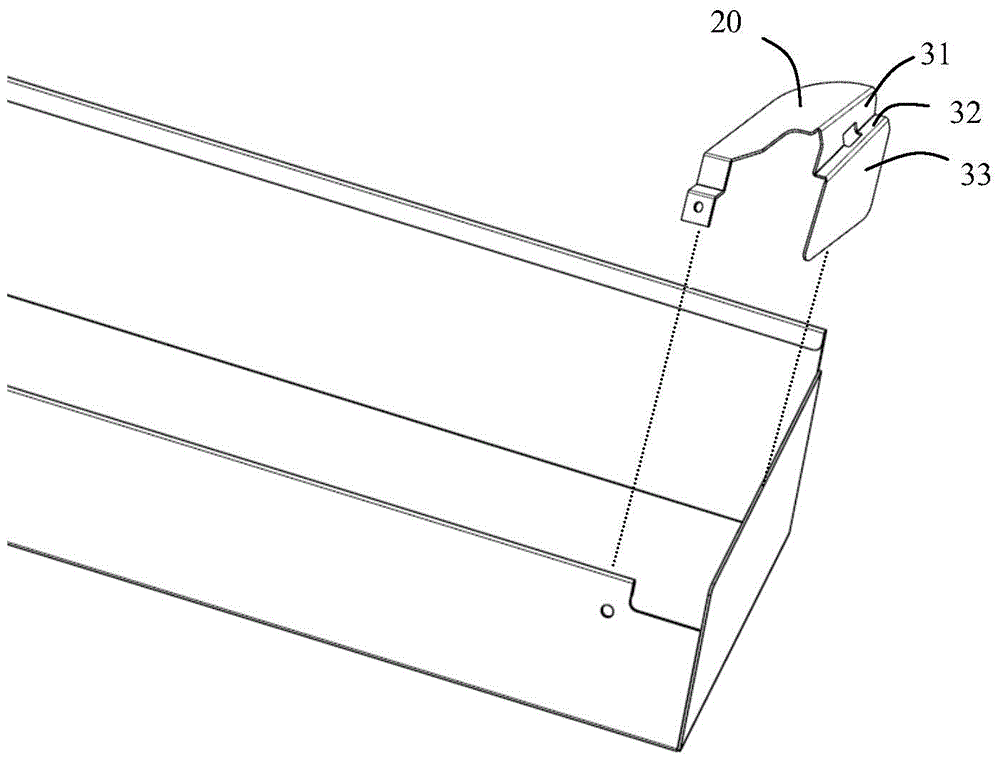

[0029] Such as figure 1 As shown, figure 1 It is a perspective view of an oil cup for a range hood according to an embodiment of the present invention. The oil cup 1 for a range hood of the present invention has an open top. The oil cup 1 includes an open side wall 10 and a first located inside the side wall 10 for fixing the oil cup 1 on the range hood. Fixing pieces 20. Please refer to figure 2 , figure 2 It is a perspective view of an oil cup according to an embodiment of the present invention. The oil cup 1 further includes an oil leakage prevention part connected between the side wall 10 and the first fixing member 20, and the oil leakage prevention part has a side adjacent to the side wall 10 and A recessed space 300 lower than the top end of the side wall 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com