Yaw brake of wind power generation device and controlling method thereof

A technology for wind power generation equipment and yaw brakes, which is applied to the types of brakes, axial brakes, mechanical equipment, etc., can solve problems such as fan out of control, failure to brake, and no mention of the improvement of hydraulic loading cylinder oil leakage. Achieve the effect of reducing working pressure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

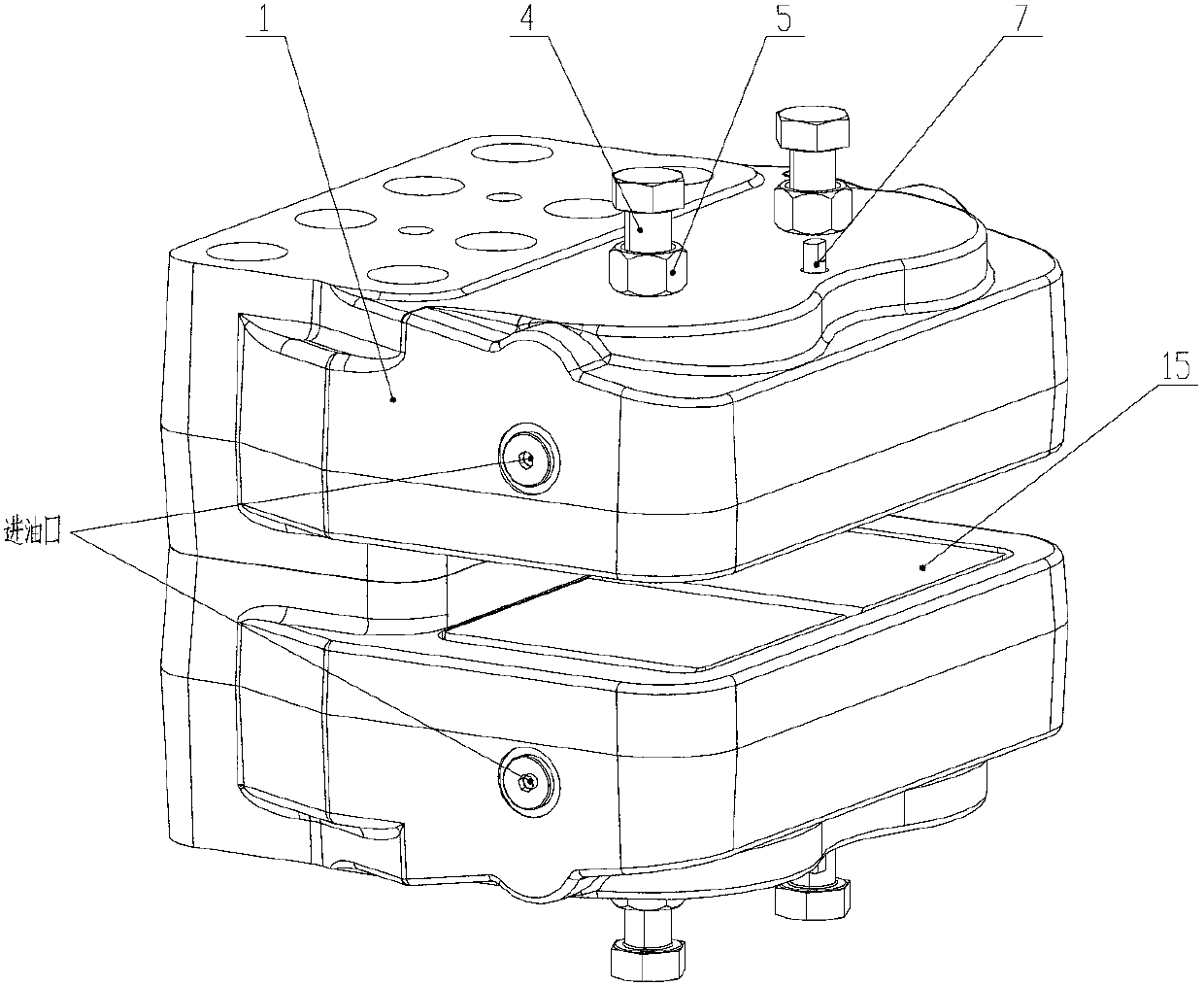

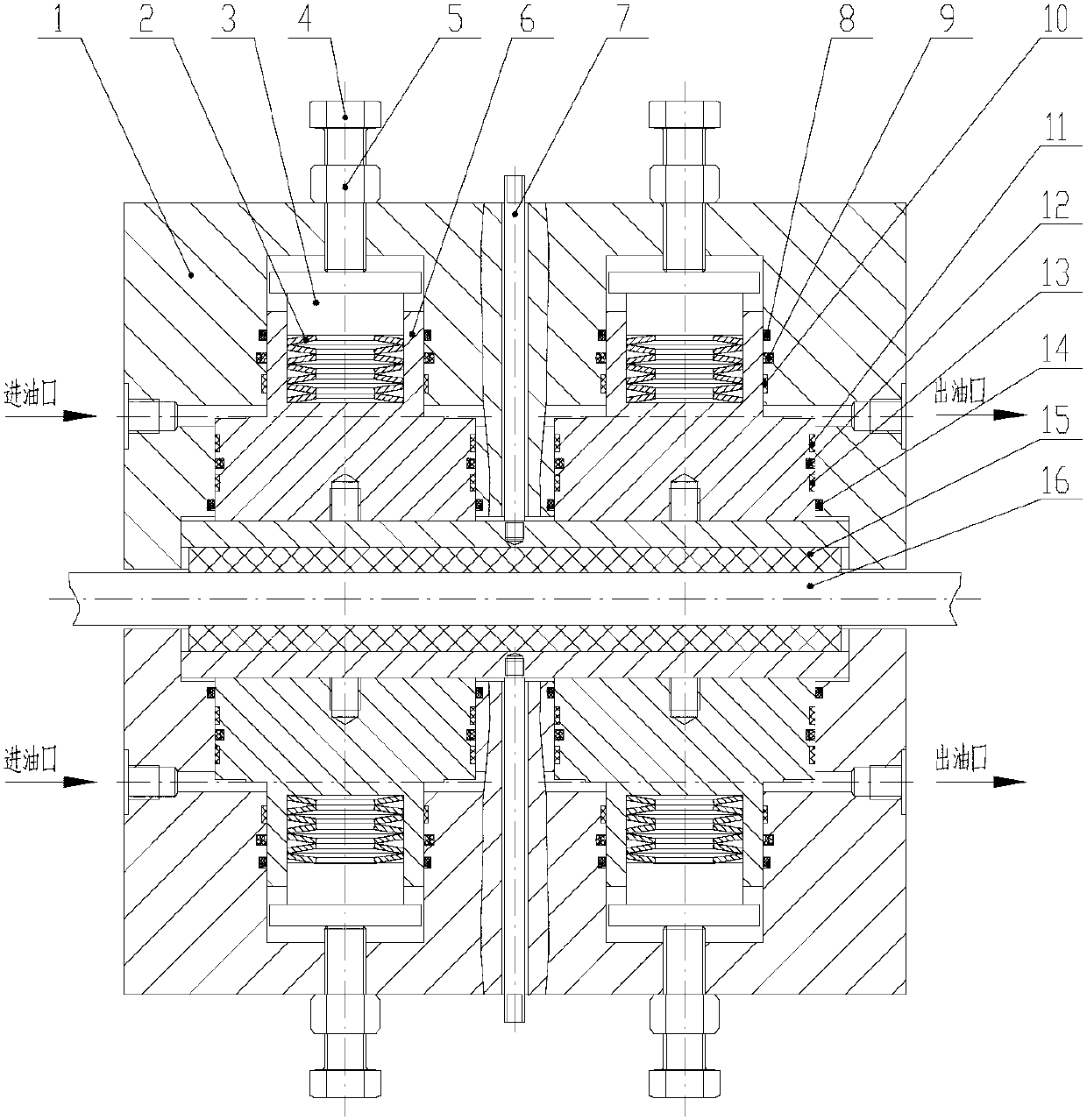

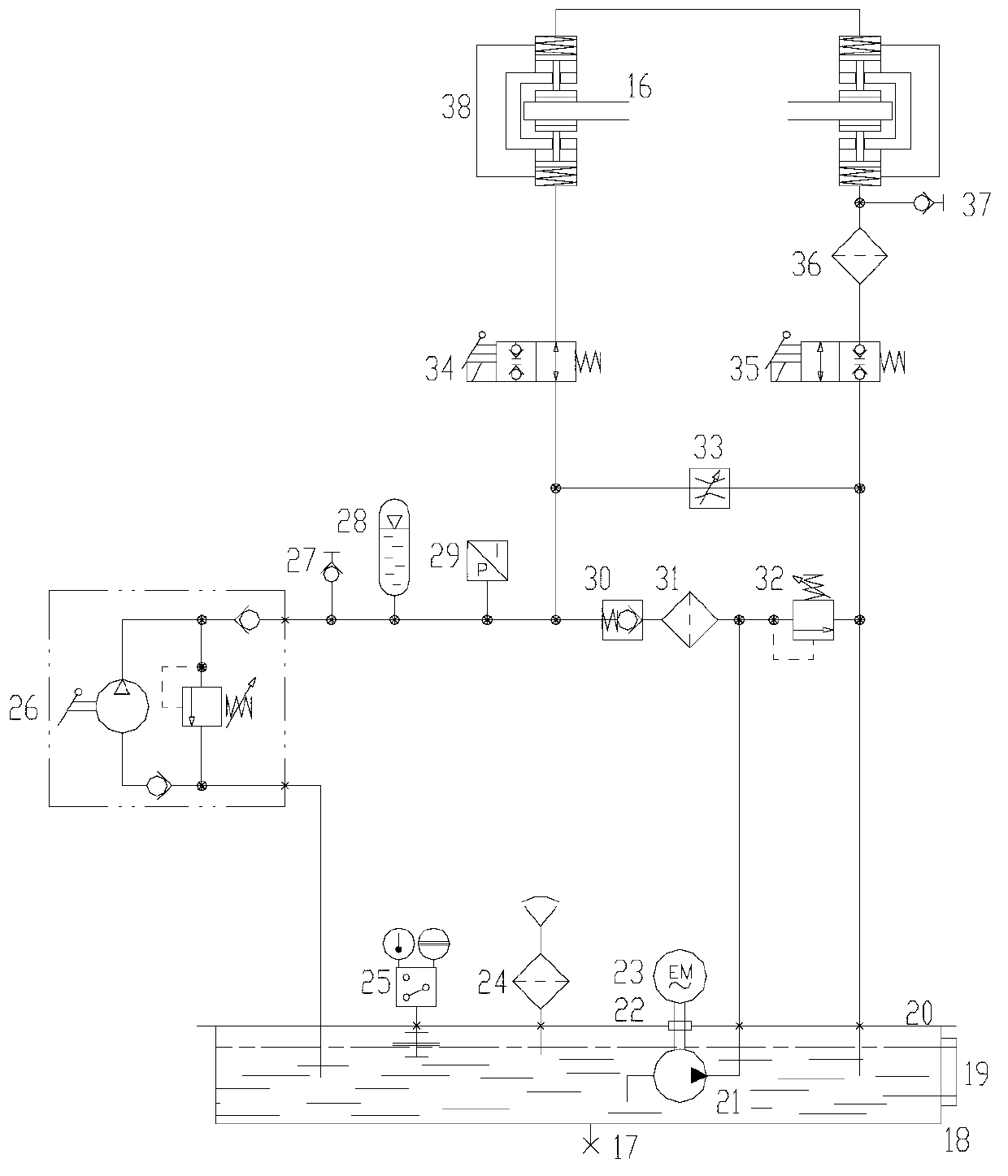

[0039] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a yaw brake for wind power generation equipment includes two brake calipers with identical structures, and the two brake calipers are symmetrically installed on the upper and lower sides of the brake disc 16 through eight high-strength bolt connections; The brake caliper has a left-right symmetrical structure, including brake bracket 1, disc spring group 2, guide block 3, adjusting bolt 4, lock nut 5, piston 6, wear indicator 7, dust-proof ring A8, high-pressure sealing ring A9 , guide belt A10, guide belt B11, high-pressure sealing ring B12, guide belt C13 and dust-proof ring B14, two oil cylinders are processed on the brake bracket 1, a piston 6 is installed in the oil cylinder, and a piston 6 is provided with an installation The counterbore of the disc spring group 2, the disc spring group 2 is compressed and installed in the counterbore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com