Solid smoke cartridge, electronic cigarette heating component using solid cartridge and electronic cigarette

A technology for heating components and solid cigarettes, applied in the field of electronic cigarettes, can solve the problems of inability to directly smoke with solid substances, difficult to overcome the leakage of e-liquid, unsanitary adding e-liquid, etc. The effect of oil spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

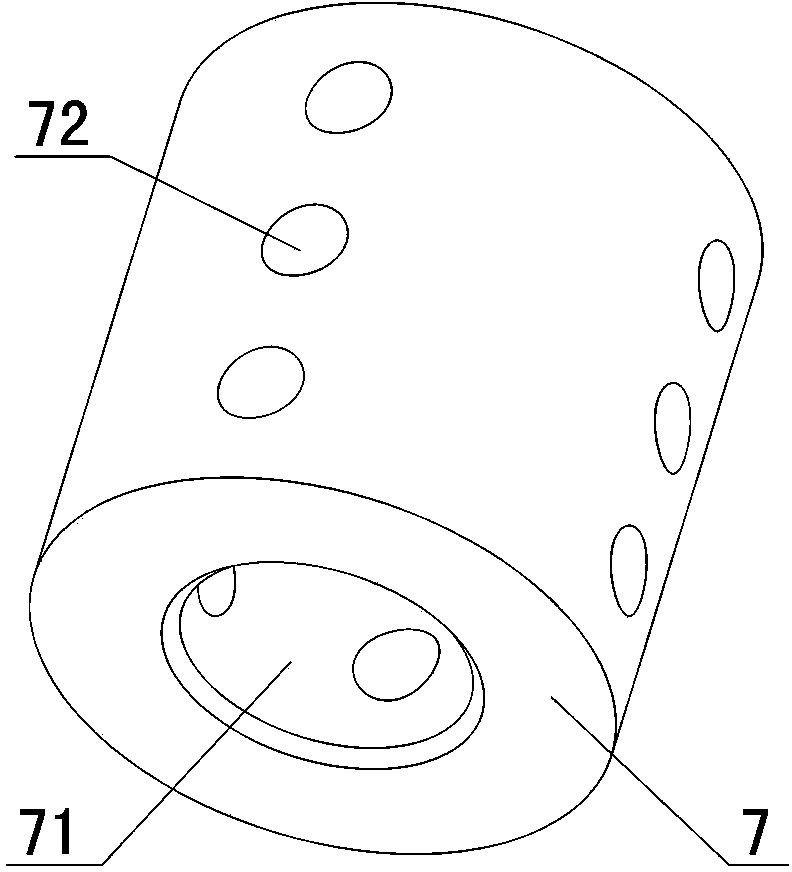

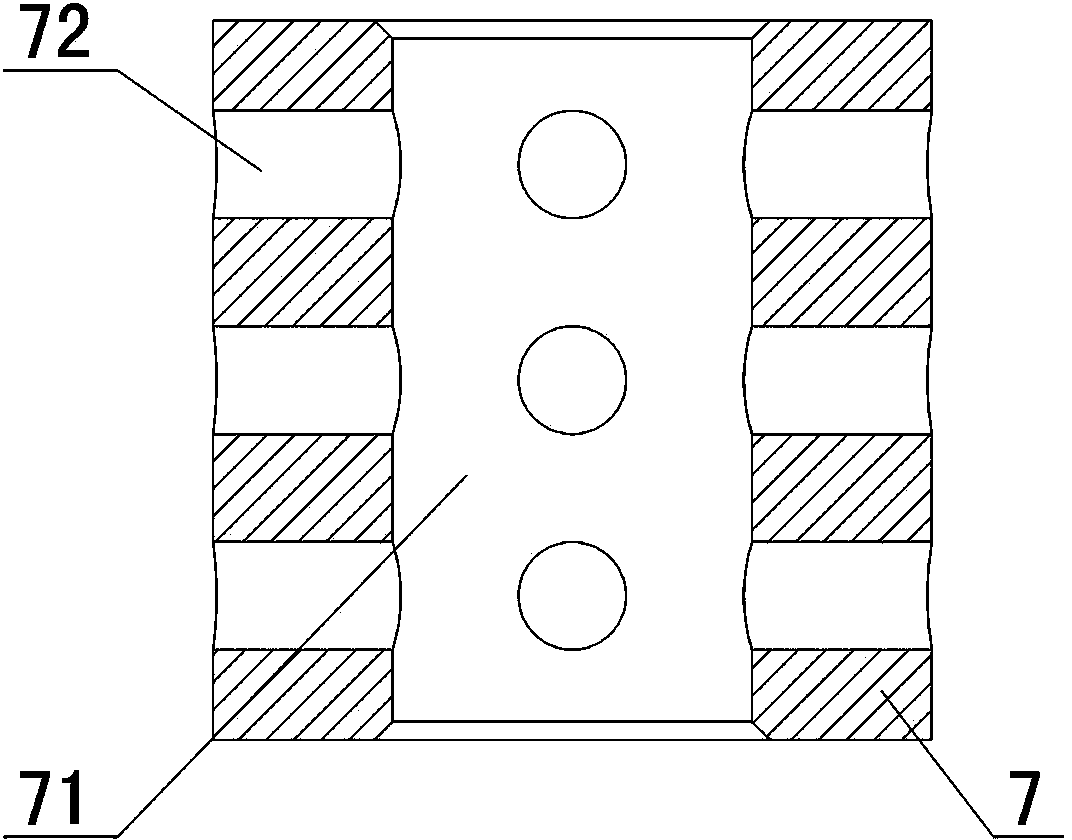

[0037] Such as figure 1 and figure 2As shown, the solid pod of this embodiment includes the pod body 7 obtained by adding an atomizing agent to the tobacco particles, mixing, stirring, and compression molding in sequence. Solvent; the cartridge body 7 is cylindrical, and the axis of the cartridge body 7 is provided with a main air hole 71 , and the side wall of the cartridge body 7 is provided with a plurality of auxiliary air holes 72 respectively communicating with the main air hole 71 . The pod body 7 of this embodiment is obtained by adding an atomizing agent to tobacco particles, mixing and stirring, and molding in sequence, and the atomizing agent includes an edible organic solvent with an atomizing temperature of 150-350°C. The atomizing agent can Ensure that the tobacco particles can be heated and atomized without burning at a temperature of 150-350°C, which can overcome the shortcomings of liquid e-liquid or solid-liquid mixed e-liquid that is not pure enough in tas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com