Dynamic high-pressure calibration device of flat type pressure sensor

A pressure sensor and calibration device technology, applied in the direction of measurement device, force/torque/work measuring instrument calibration/test, measurement of fluid pressure, etc., can solve problems such as flat pressure sensors that have not yet been seen, and achieve successful loading, Guaranteed effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

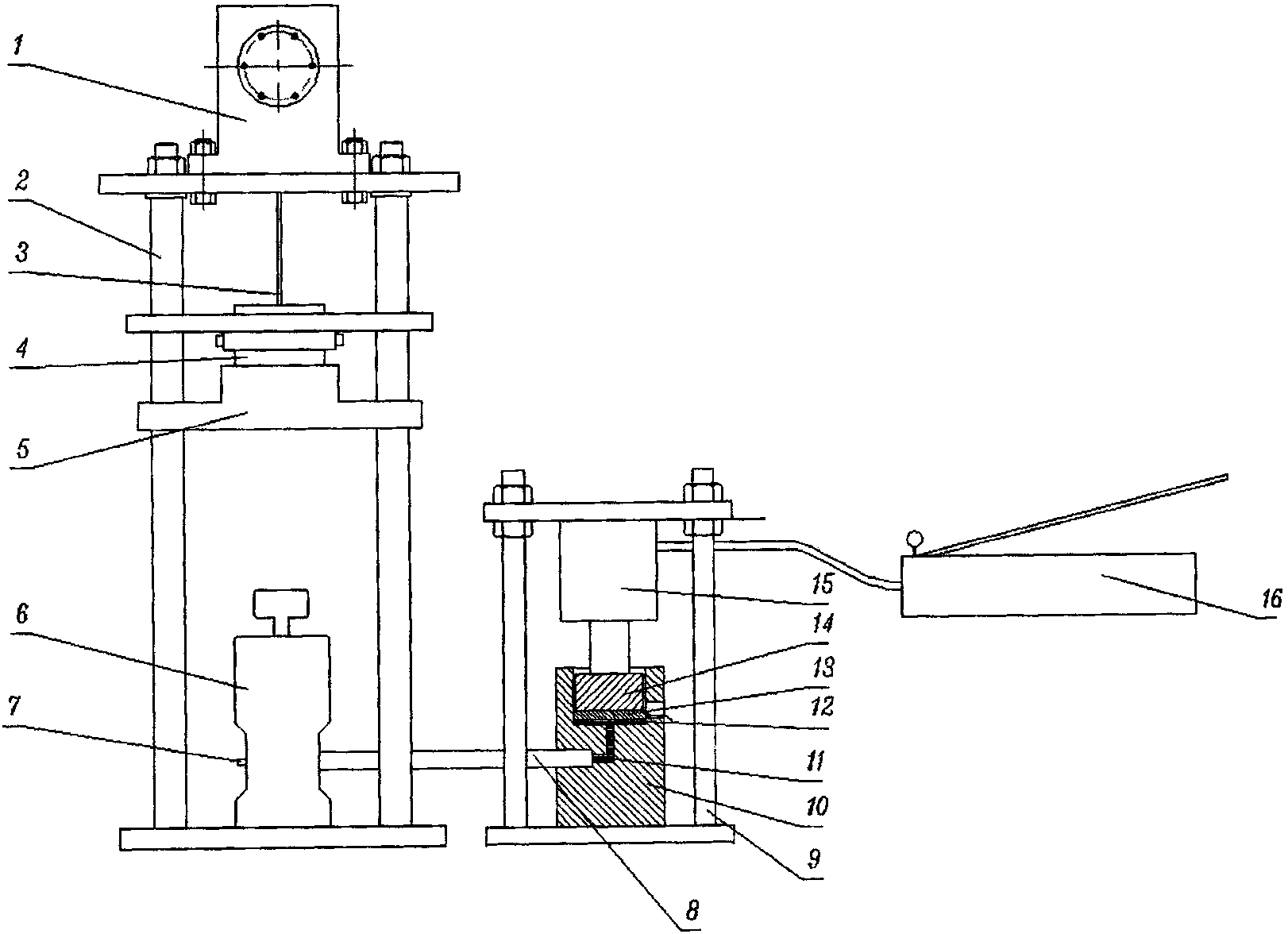

[0012] see figure 1 , the flat type pressure sensor dynamic high-voltage calibration device of the present invention includes two parts, one part is a drop hammer hydraulic type high-voltage generator, which consists of a motor assembly 1, a bracket assembly 2, a steel wire rope 3, a magnet assembly 4, a weight 5, and a pressure generating device. The bracket component 2 is vertically installed and fixed on the ground, and the motor component 1 is installed on the top of the bracket component 2. One end of the wire rope 3 is connected to the motor component 2, and the other end is connected to the magnet component 4. The magnet component 4 There are circular guide holes on both sides of the bracket assembly 2 and the weight 5. The support column of the bracket assembly 2 passes through the magnet assembly 4 and the weight 5 through the guide holes. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com