Preparation method of hybrid hollow sphere metal-matrix lightweight composite material

A composite material and hollow sphere technology, which is applied in the field of preparation of hybrid hollow sphere metal matrix lightweight composite materials, can solve the problems of high cost, complex preparation process, high density, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

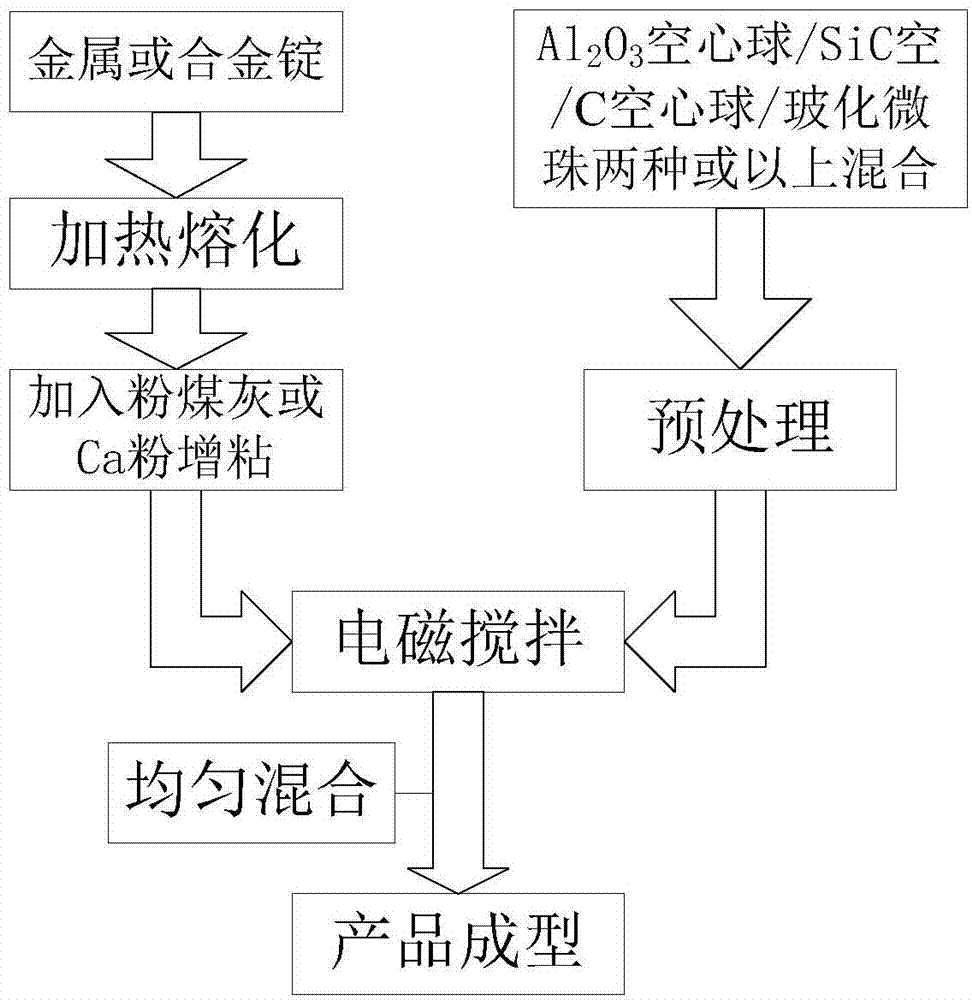

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the aluminum alloy material is selected as the metal base 3, and SiC hollow spheres and Al alloys mixed in any proportion are selected. 2 o 3 Hollow ball 4, the diameter of the hollow ball is 0.5mm-5mm, SiC hollow ball and Al 2 o 3 The hollow sphere has a high melting point and high hardness, and can be fully mixed with aluminum alloy without significantly reducing the compressibility of the alloy material.

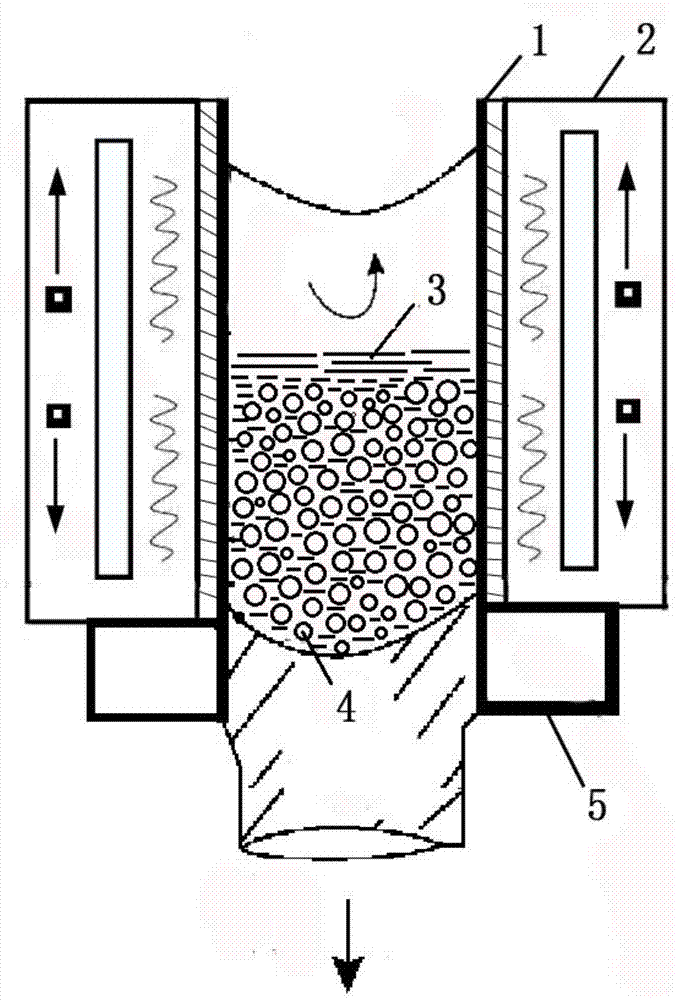

[0028] The mold used for the preparation method (see figure 2 ) consists of a furnace 1, an electromagnetic stirring device and an electromagnetic stirring heating furnace 2 formed by a heating device, and a cooler 5. The preparation steps are as follows: firstly add a commercially available aluminum alloy ingot into the electromagnetic stirring heating furnace 2, heat it to 500-650° C. to melt and then keep it warm; then weigh the aluminum alloy ingot according to 1.0%-5.0% (mass fraction) The tackifier is added to the electromagnetic stir...

Embodiment 2

[0031] This embodiment is compared with embodiment 1, and difference is that the Al of large diameter is selected for use 2 o 3 Hollow spheres and SiC hollow spheres with smaller diameters, in which Al with a diameter of 1-5mm 2 o 3 The amount of hollow spheres added accounts for 20%-50% of the volume of the liquid aluminum alloy, the amount of SiC hollow spheres with a diameter of 0.5-1mm added accounts for 3-5% of the volume of the liquid aluminum alloy, and the rest of the conditions are the same. The small-diameter SiC hollow spheres on the one hand play the role of increasing the viscosity of the aluminum liquid to improve the uniformity of the composite material, and at the same time can fill the large-sized Al 2 o 3 The voids between the hollow spheres further reduce the density of the composite material. Take out the molded metal matrix composite, weigh and calculate the density and porosity, and use the compression test method to test its mechanical properties. C...

Embodiment 3

[0033] This embodiment is compared with embodiment 2, except the large-diameter Al in the selected hollow sphere 2 o 3 In addition to hollow spheres and SiC hollow spheres with smaller diameters, the types of hollow spheres also include C hollow spheres and vitrified microspheres. The four types of hollow spheres are mixed in any proportion, and the viscosity enhancer is selected at 3%-5% (mass fraction) The fly ash to further reduce production costs, the rest of the conditions are the same.

[0034] Take out the molded metal matrix composite, weigh and calculate the density and porosity, and use the compression test method to test its mechanical properties. Compared with the existing method of preparing hollow sphere composite materials, this method uses 4 kinds of mixed hollow spheres with different particle sizes as fillers. Under the premise of ensuring the material performance, the porosity can reach more than 50%, thereby minimizing the Material density, while also fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com