Method for preparing stoneware batten for fabricated building by utilizing industrial solid waste

An industrial solid waste, prefabricated technology, applied in applications, household appliances, clay products, etc., can solve the problems of poor industrial solid waste treatment technology, low capacity, and inability to effectively utilize industrial solid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

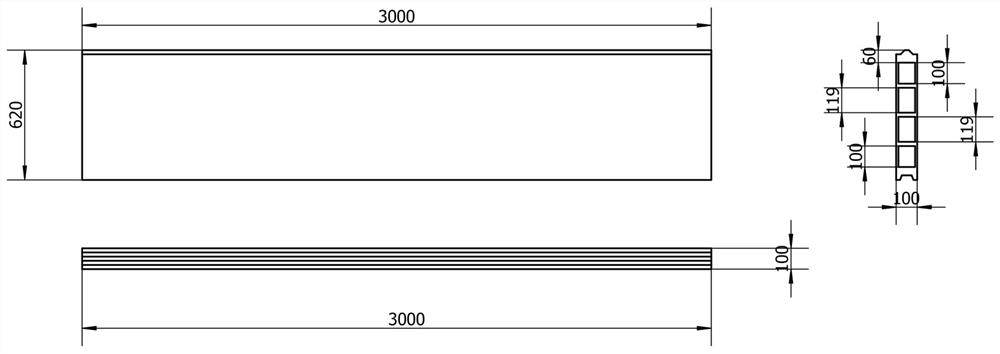

Image

Examples

preparation example Construction

[0042] A method for preparing a prefabricated building stone slab prepared from industrial solid waste, comprising the following steps:

[0043]Step 1. Preparation of formula raw materials: solid waste raw materials and mineral raw materials are dried, crushed and screened separately; the drying process uses a gas dryer, and the dried raw materials have a moisture content of 1 to 10%; the crushing process uses a jaw crusher for coarse Crushed to 30±1mm, finely crushed by hammer crusher to 5±0.5mm, pulverized by Raymond machine or vertical mill to less than 100 mesh, to obtain materials with a certain particle size distribution; the screening process is to combine solid waste raw materials and Mineral raw materials are screened into materials with a certain particle size distribution, among which solid waste raw materials are screened into 8-20 mesh as aggregate, accounting for 5-40% of the mass, ore raw materials are screened into 20-1000 mesh as filler, and the mass is Accoun...

Embodiment 1

[0052] A prefabricated stone slab for construction prepared from industrial solid waste, which is formed by mixing solid powder and water in a weight ratio of 1:0.1; in terms of weight percentage, the composition of the solid powder is as follows:

[0053] Solid waste raw materials: 75%; solid waste raw materials are blast furnace slag, converter slag, manganese slag and iron tailings;

[0054] Mineral raw materials: 15%; said mineral raw materials are fluorite, limestone and calcite;

[0055] Chemical raw materials: 10%; the chemical raw materials are sodium humate and hydroxymethyl cellulose.

[0056] A method for preparing a prefabricated building stone slab prepared from industrial solid waste, comprising the following steps:

[0057] Step 1. Preparation of formula raw materials: solid waste raw materials and mineral raw materials are dried, crushed and screened separately; the drying process uses a gas dryer, and the dried raw materials have a moisture content of 1%; the...

Embodiment 2

[0067] A prefabricated building stone slab prepared by utilizing industrial solid waste, which is formed by mixing solid powder and water in a weight ratio of 1:0.25; in terms of weight percentage, the composition of the solid powder is as follows:

[0068] Solid waste raw materials: 95%; solid waste raw materials are oil shale slag, oil shale tailings, coal gangue and fly ash;

[0069] Mineral raw material: 3%; said mineral raw material is potassium feldspar and albite;

[0070] Chemical raw material: 2%; said chemical raw material is phenolic resin.

[0071] A method for preparing a prefabricated building stone slab prepared from industrial solid waste, comprising the following steps:

[0072] Step 1. Preparation of formula raw materials: solid waste raw materials and mineral raw materials are dried, crushed and screened separately; the drying process uses a gas dryer, and the dried raw materials have a moisture content of 10%; the crushing process uses a jaw crusher for co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com