Anti-static foam glass heat insulation and cold insulation material and preparation method thereof

A foam glass and anti-static technology, which is applied in the field of inorganic functional materials, can solve the problems of high anti-static requirements for building materials, high requirements for fire protection, and high flammability and explosion, and achieve expanded use space and application range, good chemical stability, and permanent Effect of Static Dissipative Function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

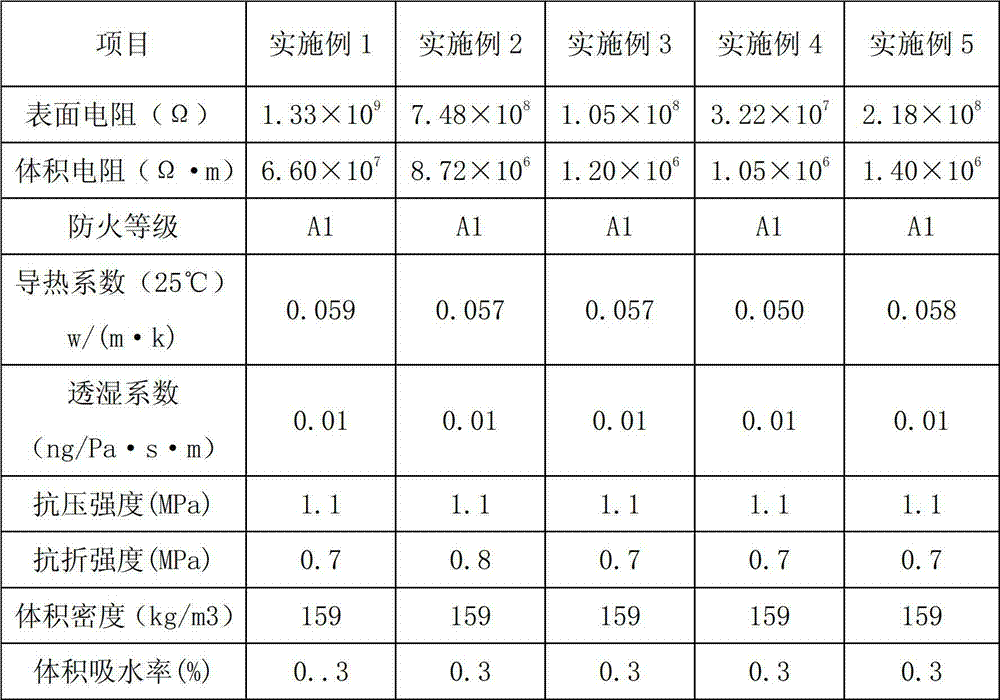

Examples

Embodiment 1

[0019] Select 95% white corundum material as the inner lining of the grinding machine, and use 95% white corundum balls of different specifications to crush and grind ordinary flat glass, carbon black powder, metal powder and foaming agent into 100-mesh powder respectively . Due to the high hardness of white corundum, impurities can be avoided to affect product quality. Then weigh 0.2% nickel powder and 0.2% aluminum oxide by mass fraction, and 1% foaming agent and the rest of ordinary flat glass powder, mix them evenly, and put them into a mold box with specific specifications. The specifications of the rectangular mold box are less than 800 mm in length, 600 mm in width, and 200 mm in thickness, and the specifications of the curved mold box are less than 600 mm in length, 30-180 degrees in arc, and less than 200 mm in thickness. Push the mold box containing the mixed powder into the front section of the heating kiln for preheating and drying at 450-600°C, control the temper...

Embodiment 2

[0022] Select 95% white corundum material as the inner lining of the grinding machine, and use 95% white corundum balls of different specifications to crush and grind ordinary flat glass, carbon black powder, metal powder and foaming agent into 200-mesh powder respectively . Due to the high hardness of white corundum, impurities can be avoided to affect product quality. Then weigh 0.2% of carbon powder and 0.2% of antimony trioxide, 1% of blowing agent and the rest of ordinary flat glass powder according to the mass fraction, mix them evenly, and put them into a mold box of a specific size. The specifications of the rectangular mold box are less than 800 mm in length, 600 mm in width, and 200 mm in thickness, and the specifications of the curved mold box are less than 600 mm in length, 30-180 degrees in arc, and less than 200 mm in thickness. Push the mold box containing the mixed powder into the front section of the heating kiln for preheating and drying at 450-600°C, contro...

Embodiment 3

[0025] Select 95% white corundum material as the inner lining of the grinding machine, and use 95% white corundum balls of different specifications to crush and grind ordinary flat glass, carbon black powder, metal powder and foaming agent into 100-mesh powder respectively . Due to the high hardness of white corundum, impurities can be avoided to affect product quality. Then weigh 0.2% carbon powder and 0.2% titanium powder according to mass fraction, and 1% foaming agent and the rest of ordinary flat glass powder. The box specification is less than 800 mm in length, 600 mm in width, and 200 mm in thickness. Push the mold box containing the mixed powder into the front section of the heating kiln for preheating and drying at 450-600°C, control the temperature to prevent oxidation, and sinter, oxidize and foam at the middle section of the heating kiln at 600-900°C, control the temperature and Time (20-50 minutes) to make the foaming uniform, cool down to below 600°C in the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com