Viaduct structure

A technology for viaducts and bridge piers, which is applied in the directions of superstructure sub-assemblies, connections between superstructure sub-assemblies, bridge parts, etc. The effect of handling and assembly, maintaining structural integrity, and short construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

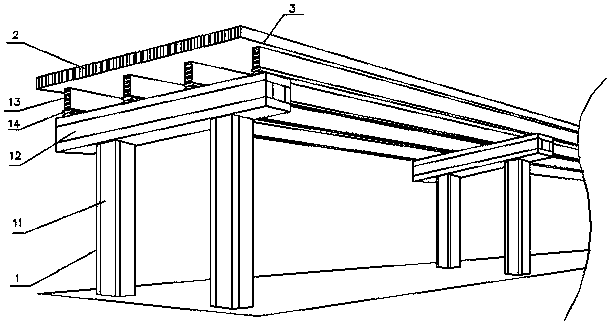

[0052] like figure 1 Shown: a viaduct structure, including a bridge deck 3 and a support body 1 for supporting the bridge deck 2 . Wherein, the supporting body 1 includes a bridge pier 11, a cover beam 12 and a support beam 13, the cover beam 12 is arranged on the bridge pier 11, the support beam 13 spans between a plurality of cover beams 12 through a support 14, and the bridge deck 3 is connected to the support Beam 13 on.

[0053] The piers 11 , cover beams 12 , support beams 13 and bridge deck 3 of this embodiment are all made of metal plates 2 . Wherein, both the support beam 13 and the bridge deck 3 are spliced by a plurality of metal plates 2, and the number of metal plates 2 depends on the length of the bridge. Both the pier 11 and the cover beam 11 are spliced by four metal plates 2 to form a columnar structure.

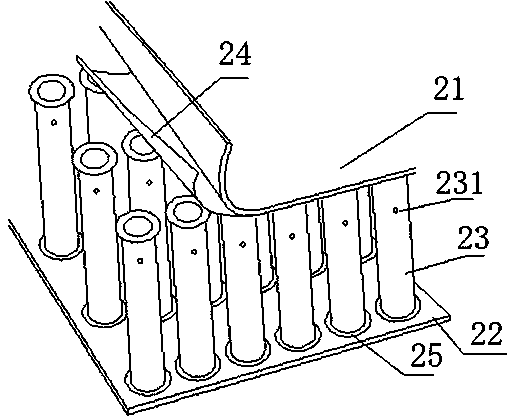

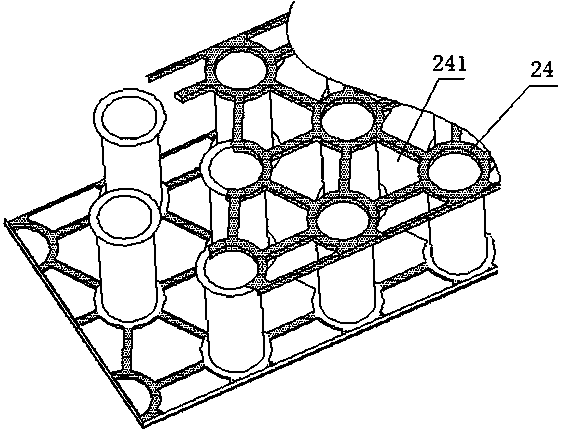

[0054] like figure 2 and image 3 As shown: in this embodiment, the metal plate 2 includes a first panel 21, a second panel 22 and a plurality of ...

Embodiment 2

[0064] like Figure 5 Shown: The difference with Embodiment 1 is that the bridge deck is an arc structure, and its first panel 21' and second panel 22' are curved panels. The two ends of the hollow pipe 23' are vertically connected with the contact surface of the panel. The linetype of curved panels is arc. A plurality of hollow tubes 23' are arranged at intervals, and the axis of each hollow tube 23' is perpendicular to the tangent line of the corresponding arc-shaped contact surface. In this way, the connection strength between the hollow tube 23' and the panel can be enhanced, and the occurrence of hollow tubes can be avoided. Many positions are not welded, or gaps or voids are generated, resulting in uneven brazing. This solution can greatly improve the overall strength and quality.

[0065] The first panel 21' and the second panel 22' have the same curvature.

[0066] Other structures are with embodiment 1.

Embodiment 3

[0068] like Image 6 Shown: the difference with embodiment 1 is that the bridge deck is an arc structure, and its first panel 21 " is an arc-shaped curved panel, and the second panel 22 " is a plane panel, and the flanging at one end of the hollow tube 23 " and The plane boards are parallel, and the flanging at the other end is an inclined plane, and the inclined plane is parallel to the contact surface of the curved boards, so that when the hollow tube is connected with the two boards, there will be no gap.

[0069] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com