Gypsum board with composite glass fiber veneering felts on surfaces

A technology of glass fiber and veneer felt, which is applied in the direction of glass/slag layered products, floors, layered products, etc., can solve the problems of overall structural deformation, unsolvable, and restricting the service life and functional effects of gypsum boards, and achieve The effect of improving quality, improving fire performance, and good vertical and horizontal bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with specific embodiment:

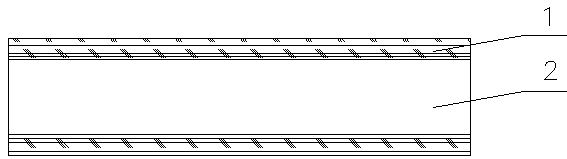

[0018] Such as figure 1 As shown, the surface of the gypsum board with composite glass fiber facing mat is mainly composed of a gypsum board core layer 2 and a composite glass=fiber facing mat 1 attached to the outside of the gypsum board core layer. The composite glass fiber veneer mat is made of the following raw materials in weight ratio: 35-50 parts by weight of glass fiber chopped strands, 30-45 parts by weight of polyester fiber, 10-25 parts by weight of wood fiber, wherein glass fiber Chopped strands are 30-35 microns in diameter and 30-35 mm in length, polyester fibers are 20-30 microns in diameter and 30-35 mm in length, and wood fibers are 14-20 microns in diameter and 20-30 mm in length.

[0019] As a preferred solution, the performance index of the composite glass fiber facing mat 1 made: the mass per unit area is 100g / m 2 , the thickness is 1.0 mm, the longitudin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com