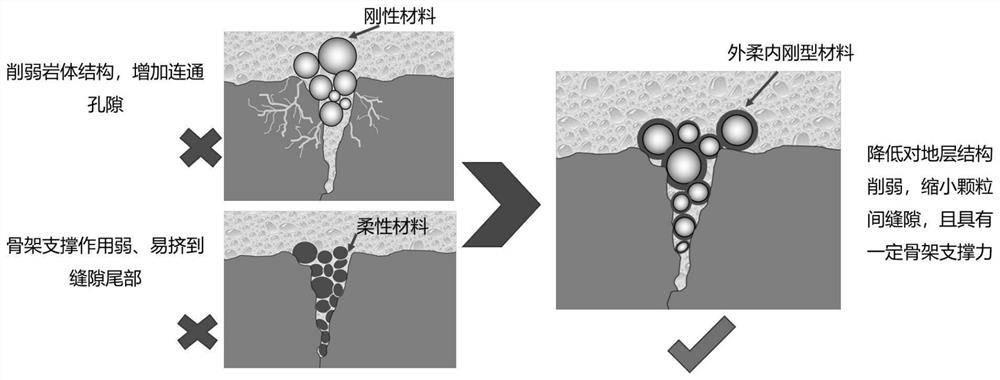

Lost circulation material with soft outside and rigid inside and preparation method thereof

A plugging material and rigid material technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of inorganic calcium carbonate falling off, affecting on-site construction, affecting the fluidity of cement slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Modification method of rigid material quartz sand:

[0039] (1) First pre-hydrolyze KH570, mix 4g KH570, 75g absolute ethanol, and 25g distilled water into beaker A, adjust pH=4~5 with dilute hydrochloric acid, transfer to a three-necked flask, stir vigorously at room temperature for 30min, and complete pre-hydrolysis .

[0040] (2) Add 100 g of absolute ethanol and 20 g of quartz sand into beaker B, place it in an ultrasonic cleaner to vibrate for 20 min, and transfer it to a three-neck flask.

[0041] (3) Introduce nitrogen and raise the temperature to 70°C, react at a stirring speed of 350r / min for 5 to 6 hours, stop the reaction, wash with absolute ethanol for 3 to 4 times after cooling, filter and dry to obtain modified quartz sand.

Embodiment 2

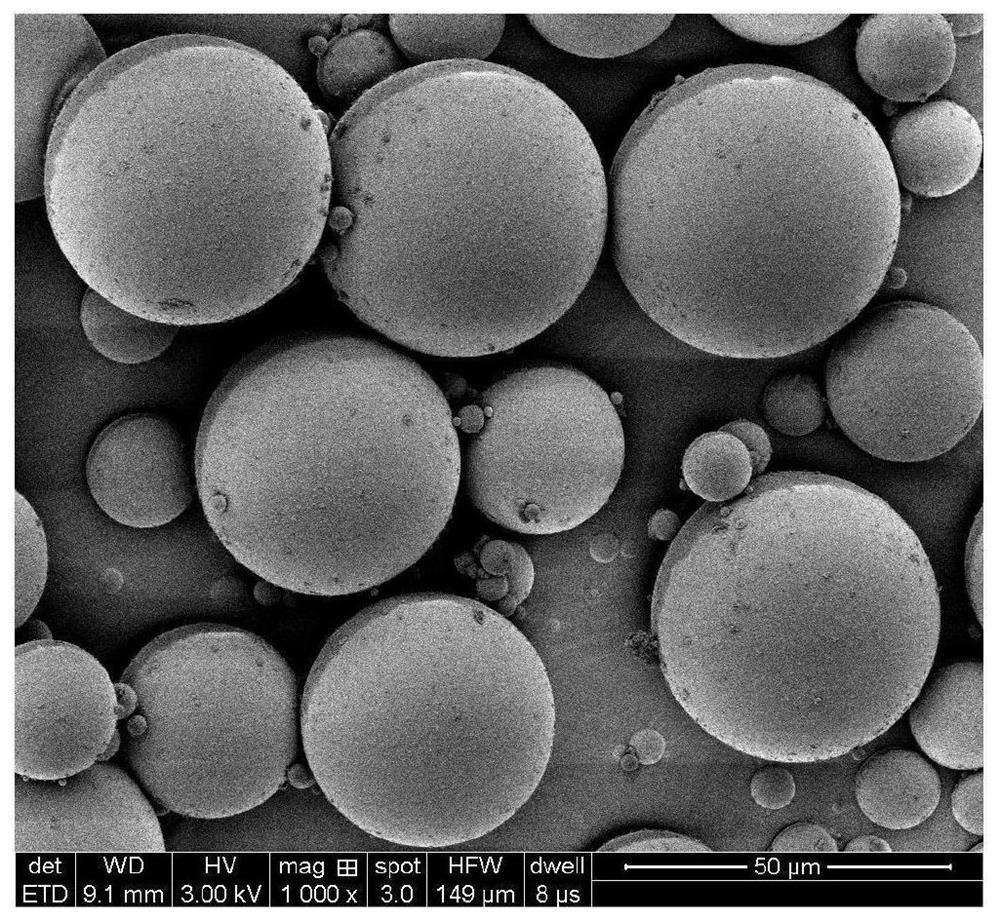

[0043] The preparation method of the gel microsphere not including the modified rigid material, the specific steps include:

[0044] (1) Add 80 g of cyclohexane and 4 g of Span-80 into a three-necked flask equipped with a reflux condenser, stirring blades and a nitrogen pipe, and stir at 30° C. for 20 minutes at high speed to obtain a continuous phase.

[0045] (2) Weigh 40g of distilled water in a beaker, add 14g of acrylamide, 3g of 2-acrylamido-2-methylpropanesulfonic acid, 3g of N-vinylpyrrolidone, and then add 0.1g of N,N-methylene Bisacrylamide, stirred evenly, configured as a dispersed phase.

[0046] (3) Take 20g of the prepared dispersed phase, drop it into the continuous phase at a constant speed for 30min, adjust the stirring speed to 300r / min, after stirring for 30min, adjust the temperature of the water bath to the reaction temperature of 70°C, and then dissolve an appropriate amount of 0.2g potassium persulfate-sodium bisulfite (1:1) mixed aqueous solution was a...

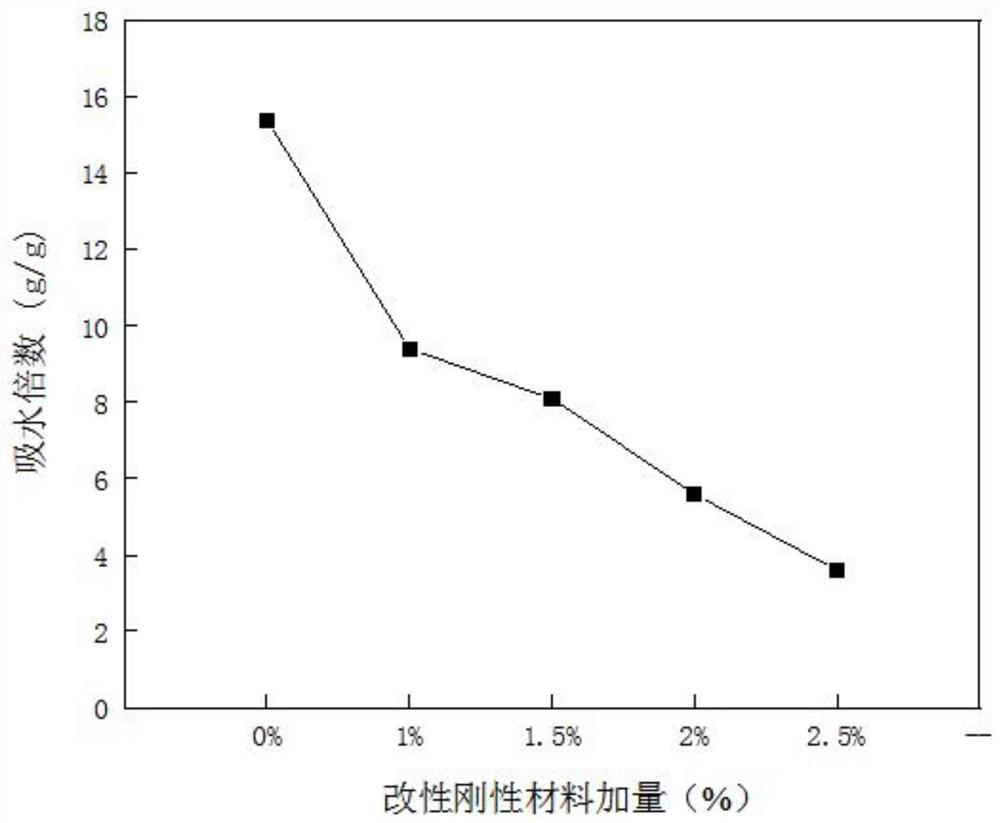

Embodiment 3

[0049] A method for preparing a plugging material that is soft on the outside and rigid on the inside, the specific steps are:

[0050] (1) Add 80g of cyclohexane, 4g of Span-80, and 0.8g of modified sand into a three-necked flask equipped with a reflux condenser, stirring blades and a nitrogen pipe, and stir at a high speed for 20min at 30°C to make Quartz sand is evenly dispersed to obtain a continuous phase.

[0051] (2) Weigh 40g of distilled water in a beaker, add 14g of acrylamide, 3g of 2-acrylamido-2-methylpropanesulfonic acid, 3g of N-vinylpyrrolidone, and then add 0.1g of N,N-methylene Bisacrylamide, stirred evenly, configured as a dispersed phase.

[0052] (3) Take 20g of the prepared dispersed phase, drop it into the continuous phase at a constant speed for 30min, adjust the stirring speed to 300r / min, after stirring for 30min, adjust the temperature of the water bath to the reaction temperature of 70°C, and then dissolve an appropriate amount of 0.2g potassium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com