Titanium-doped ternary metal organic framework material and preparation method thereof

An organic framework and ternary metal technology, which is applied in the field of titanium-doped ternary metal-organic framework materials and their preparation, can solve the problems of low catalytic efficiency, poor stability and cannot be reused, and achieves improved catalytic activity and improved hydrothermal energy. Stability, accelerated degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

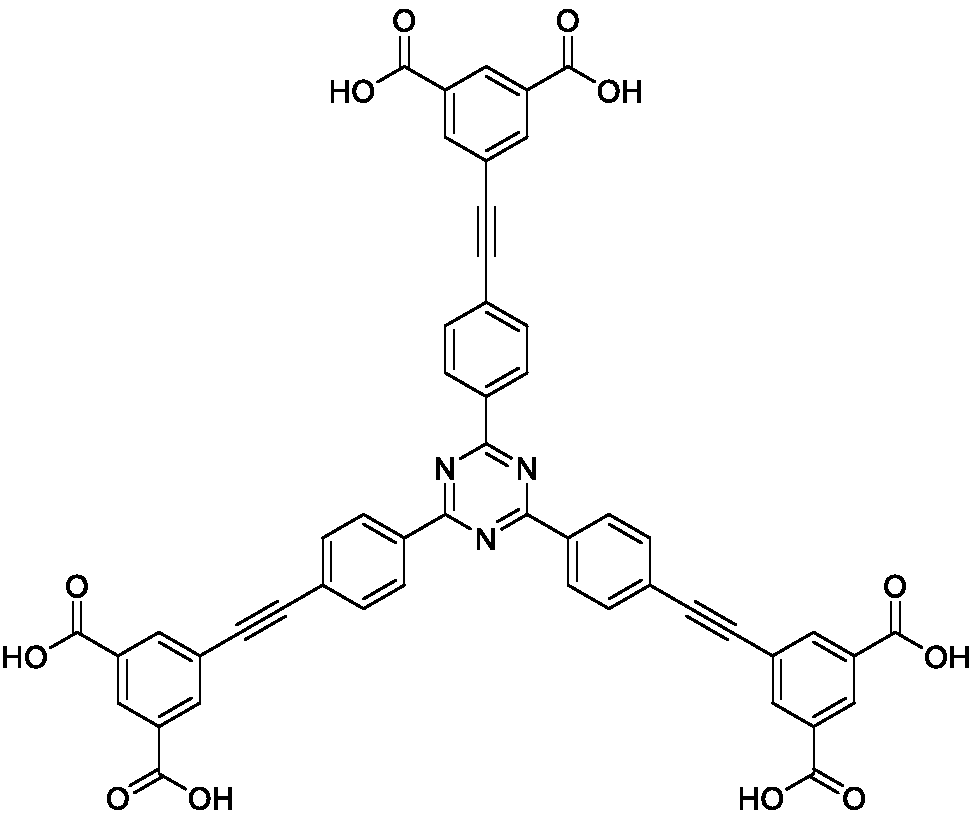

[0034] (1) Preparation of 5,5',5"-(((1,3,5-triazine-2,4,6-triyl)tri(benzene-4,1-diyl))tri(acetylene-2 ,1-diyl))triisophthalic acid

[0035] a. Mix 2.3g of 5-iododiethylphthalate and THF / iPr2NH (30mL / 10mL) solution and degas with dry Ar gas for 20min; add 85mg of bis(triphenylphosphine) dichloride and 50mg of CuI, And the mixture was stirred at 25 °C for 15 minutes; then 2,4,6-tris(4-ethynylphenyl)-1,3,5-triazine (1.0 g, 2.6 mmol) in anhydrous THF ( 10 mL) solution, and the mixture was stirred at 50 °C for 10 h. After the reaction was complete, the volatile substances were removed under reduced pressure, and the residue was added to 100 mL of deionized water and washed with CHCl 3 Extraction; the organic phase was washed successively with deionized water, brine, and MgSO 4 dry. Remove CHCl under reduced pressure 3 , and the resulting solid was purified by silica gel column chromatography with CHCl 3 / C 2 h 6 (1:1) elution gave a light yellow solid pentaethyl 5,5',5"-(((...

Embodiment 2

[0049] (1) Preparation of 5,5',5"-(((1,3,5-triazine-2,4,6-triyl)tri(benzene-4,1-diyl))tri(acetylene-2 ,1-diyl))triisophthalic acid

[0050] a. Mix 3.6g of 5-iododiethylphthalate and THF / iPr2NH (30mL / 10mL) solution and degas with dry Ar gas for 20min; add 64mg of bis(triphenylphosphine)palladium dichloride and 37.5mg CuI, and the mixture was stirred at 25°C for 15 minutes; then 2,4,6-tris(4-ethynylphenyl)-1,3,5-triazine (1.0 g, 2.6 mmol) in anhydrous solution in THF (10 mL), and the mixture was stirred at 60 °C for 10 h. After the reaction was complete, the volatile substances were removed under reduced pressure, and the residue was added to 100 mL of deionized water and washed with CHCl 3 Extraction; the organic phase was washed successively with deionized water, brine, and MgSO 4 dry. Remove CHCl under reduced pressure 3 , and the resulting solid was purified by silica gel column chromatography with CHCl 3 / C 2 h 6 (1:1) elution gave a light yellow solid pentaethyl 5,...

Embodiment 3

[0059] (1) Preparation of 5,5',5"-(((1,3,5-triazine-2,4,6-triyl)tri(benzene-4,1-diyl))tri(acetylene-2 ,1-diyl))triisophthalic acid

[0060]a. Mix 2.7g of 5-iododiethylphthalate and THF / iPr2NH (30mL / 10mL) solution and degas with dry Ar gas for 20min; add 106mg of bis(triphenylphosphine)palladium dichloride and 62.5mg CuI, and the mixture was stirred at 25°C for 15 minutes; then 2,4,6-tris(4-ethynylphenyl)-1,3,5-triazine (1.0 g, 2.6 mmol) in anhydrous solution in THF (10 mL), and the mixture was stirred at 65 °C for 12 h. After the reaction was complete, the volatile substances were removed under reduced pressure, and the residue was added to 100 mL of deionized water and washed with CHCl 3 Extraction; the organic phase was washed successively with deionized water, brine, and MgSO 4 dry. Remove CHCl under reduced pressure 3 , and the resulting solid was purified by silica gel column chromatography with CHCl 3 / C 2 h 6 (1:1) elution gave a light yellow solid pentaethyl 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com