Ozone-assisted method for catalytic decomposition of volatile organic pollutants in high-temperature flue gas

A volatile organic, high-temperature flue gas technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems that hinder the application of selective catalytic decomposition technology, reduce the catalytic decomposition temperature, etc., and achieve the improvement of catalytic decomposition efficiency , Promote catalytic decomposition, improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

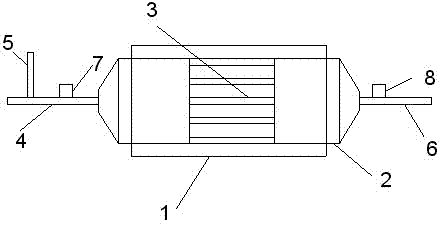

Image

Examples

Embodiment 1

[0013] The catalyst in the fixed bed reactor of the catalytic reaction is supported by carbon nanotubes, with CuO and Cu 2 O is the active component, and its active component accounts for 6% of the total mass of the catalyst. Ozone gas is introduced into the fixed bed reactor, and the concentration of the introduced ozone gas is 11.0mg / L.

[0014] Analysis and Determination of Chlorobenzene Concentration and CO Discharged from Fixed Bed Reactor Using Online Gas Chromatography 2 Concentration: In the absence of ozone, the conversion rates of chlorobenzene at 150°C, 200°C, 250°C, and 300°C were 12%, 15%, 23%, and 50% respectively; CO 2 The selectivities are 2%, 3%, 6%, and 10%, respectively. After adding ozone, the conversion of chlorobenzene increased to 87%, 88%, 80%, and 93%, respectively; 2 The selectivities were increased to 24%, 40%, 35%, and 45%, respectively.

Embodiment 2

[0016] The catalyst in the fixed-bed reactor of the catalytic reaction is supported by activated carbon, with CuO and Cu 2 O is the active component, and its active component accounts for 6% of the total mass of the catalyst. Ozone gas is introduced into the fixed-bed reactor, and the concentration of the introduced ozone gas is 16.6mg / L.

[0017] Analysis and Determination of Chlorobenzene Concentration and CO Discharged from Fixed Bed Reactor Using Online Gas Chromatography 2 Concentration: In the absence of ozone, the conversion rates of benzene at 150°C, 200°C, 250°C, and 300°C were 16%, 22%, 31%, and 62% respectively; CO 2 The selectivities were 2.5%, 4%, 7.3%, and 12.4%, respectively. After adding ozone, the conversion of benzene increased to 80%, 76%, 83%, and 92%, respectively; 2 The selectivities were increased to 25.4%, 38%, 41.6%, and 52.7%, respectively.

Embodiment 3

[0019] The catalyst in the fixed bed reactor of the catalytic reaction is based on carbon nanotubes, with CuO, Cu 2 O, FeO and Fe 2 o 3 It is an active component, and its active component accounts for 20% of the total mass of the catalyst. The ozone gas is introduced into the fixed bed reactor, and the concentration of the introduced ozone gas is 3.0mg / L.

[0020] Analysis and Determination of Toluene Concentration and CO Discharged from Fixed Bed Reactor by Online Gas Chromatography 2 Concentration: In the absence of ozone, the conversion rates of toluene at 150°C, 200°C, 250°C, and 300°C were 21%, 24.8%, 33%, and 67.5% respectively; CO 2 The selectivities were 4%, 5.2%, 11%, and 17.9%, respectively. After adding ozone, the conversion of toluene increased to 90%, 82.6%, 89%, and 95%, respectively; 2 The selectivities increased to 31.3%, 45.7%, 47.4%, and 62.5%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com