Patents

Literature

38results about How to "Improve catalytic decomposition efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ozone-assisted method for catalytic decomposition of volatile organic pollutants in high-temperature flue gas

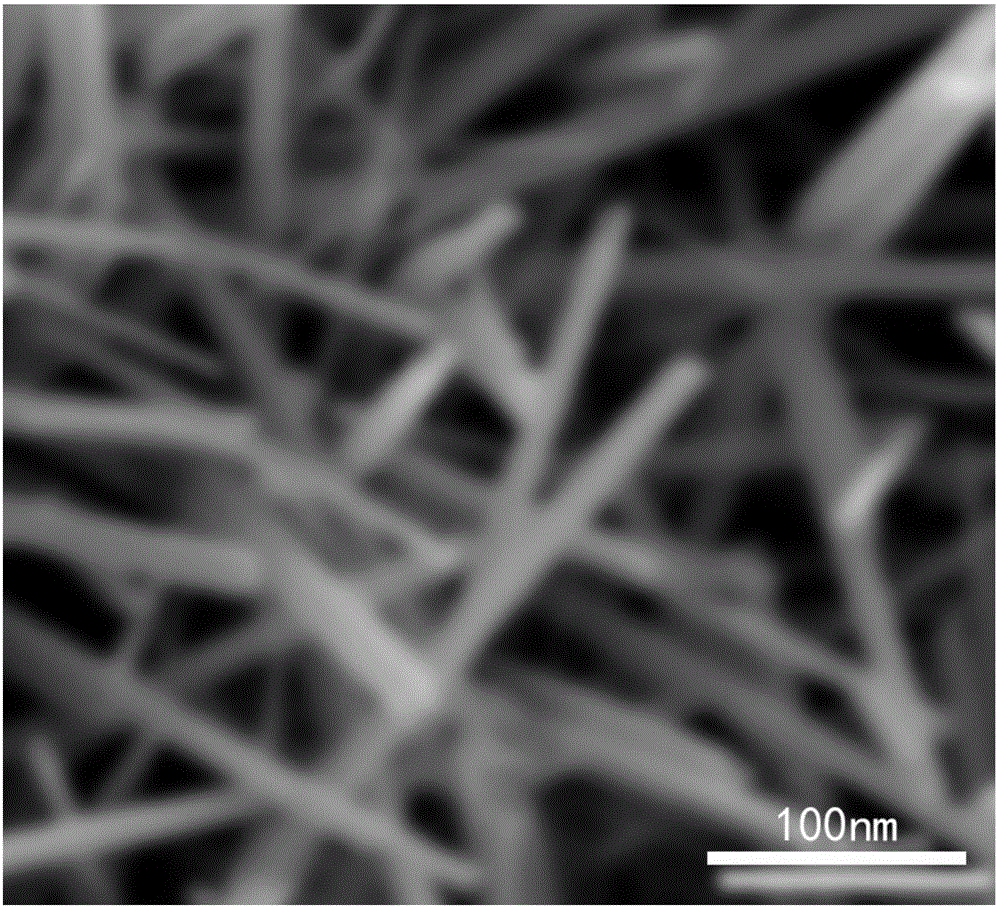

ActiveCN102814108AHighly selective adsorptionHigh selectivityDispersed particle separationCarbon nanotubeCatalytic decomposition

The invention discloses an ozone-assisted method for catalytic decomposition of volatile organic pollutants in high-temperature flue gas. According to the invention, ozone gas is introduced into a fixed bed reactor of a catalytic reaction. According to the catalyst in the fixed bed reactor, carbon nano-tubes, activated carbon, titanium dioxide, silica, or a composition thereof is adopted as a carrier; and Mn2O3, MnO2, CeO2, CuO, Cu2O, V2O5, Fe2O3, FeO, or a composition thereof is adopted as an active component. The active component accounts for 1-50% of total mass of the catalyst. The concentration of the introduced ozone gas is in a range of 0.1-50mg / L. According to the invention, a strong oxidant ozone is introduced in a catalytic decomposition process, such that active oxygen in the system is increased, catalytic decomposition of pollutant molecules is promoted, catalytic decomposition efficiency of the catalyst upon the volatile organic pollutants is substantially improved, and carbon dioxide selectivity is greatly improved. Therefore, an optimal effect of volatile organic pollutant low-temperature catalytic decomposition is achieved.

Owner:ZHEJIANG UNIV

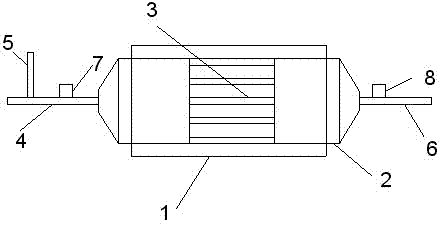

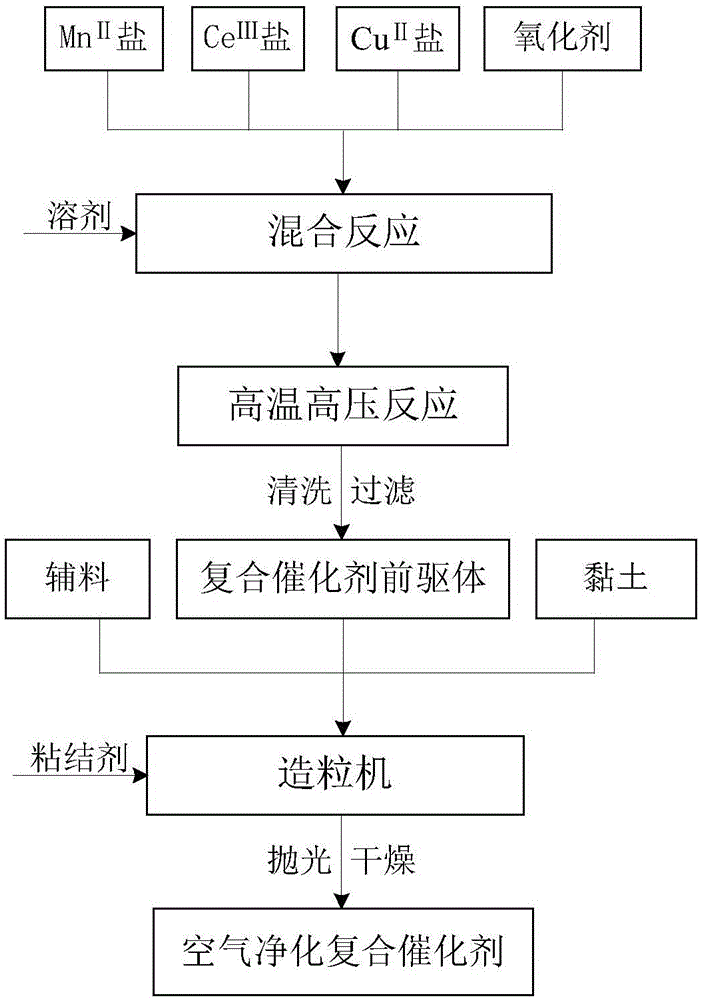

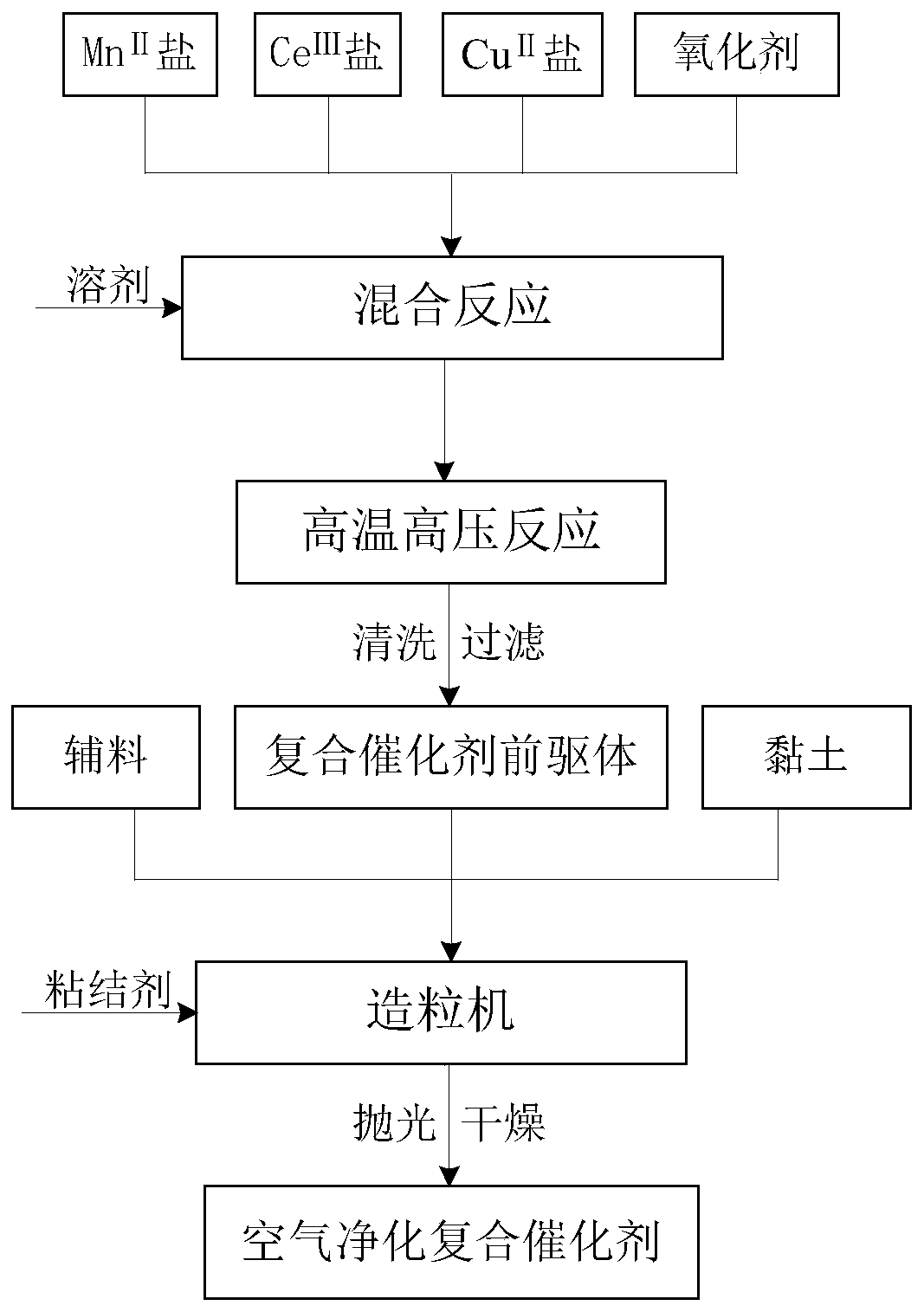

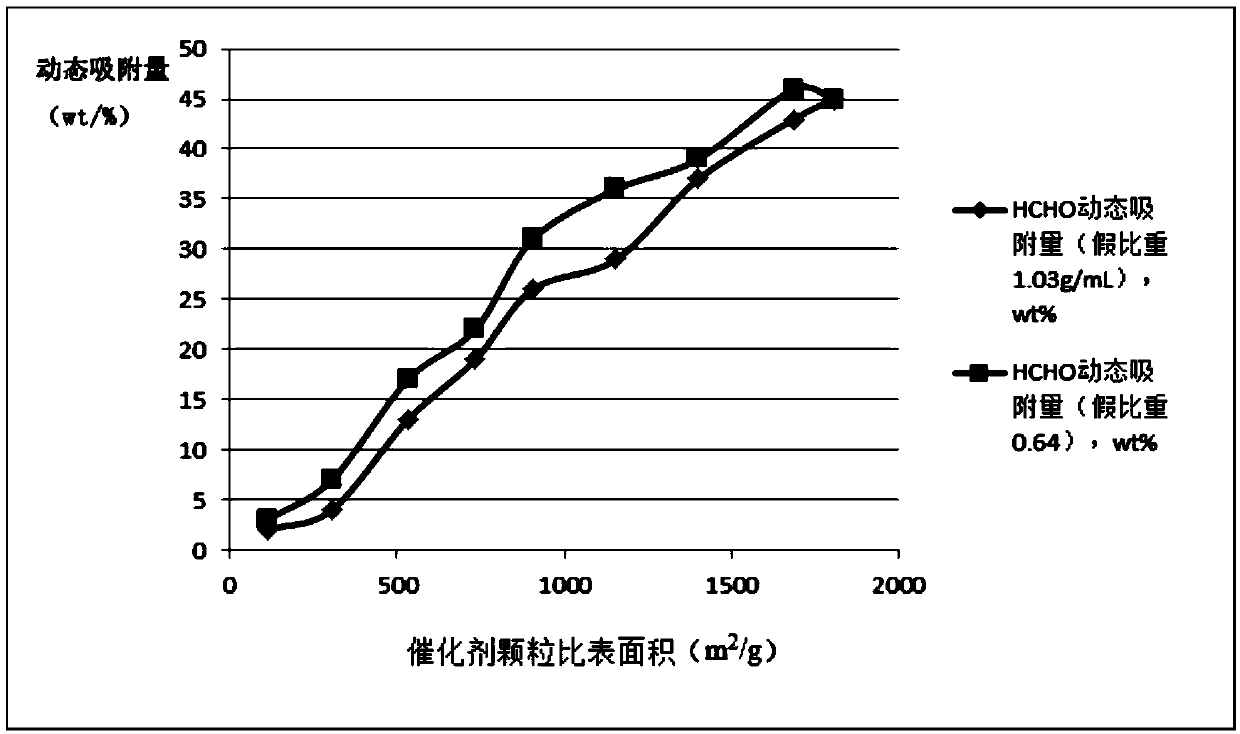

Composite air purification catalyst and preparation method thereof

ActiveCN106334565AImprove surface activityRealize catalytic decomposition reactionMolecular sieve catalystsHeterogenous catalyst chemical elementsCopper oxideSolvent

The invention discloses a composite air purification catalyst and a preparation method thereof. The composite air purification catalyst is prepared from manganese oxide composite copper oxide and cerium oxide. The preparation method comprises the steps that an oxidant, MnII salt, CuII salt and CeIII salt are dissolved in a solvent, the mixture is transferred to a high-pressure reaction kettle after mixing reaction, performs high temperature and high pressure reaction and then is filtered, cleaned and dried to obtain a composite catalyst precursor; the composite catalyst precursor is mixed with auxiliary materials and clay to get compound granulation powder; the compound granulation powder is granulated to obtain the composite air purification catalyst. The composite air purification catalyst prepared by adopting the preparation method is high in surface activity and high in catalytic performance.

Owner:UCHEER PURIFICATION & POLLUTION CONTROL TECH ZHEJIANG CO LTD

Supported metallic oxide catalyst for assisting microwave denitration and preparation method and using method thereof

ActiveCN105170150AHigh activityReduce loadDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen oxidesCatalytic decomposition

The invention discloses a supported metallic oxide catalyst for assisting microwave denitration and a preparation method and a using method thereof. The catalyst is the supported catalyst using carbon as a carrier and using a metallic oxide as an active ingredient. The carrier of the catalyst is carbon-based, is convenient to obtain, large in specific surface area and capable of playing a very good dispersing role on the active ingredient of the catalyst, and the phenomenon of ingredient agglomeration is not produced. The metallic oxide is high in activity, and required supporting amount is small. The carbon-supported metallic oxide has very good microwave absorbing ability, can well play the synergistic effect of microwaves and the catalyst, the catalytic decomposition efficiency of nitrogen oxide is high, the NO decomposition rate can be above 98%, and the catalytic decomposition temperature is low and the loss of the carbon carrier is low by means of the method.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

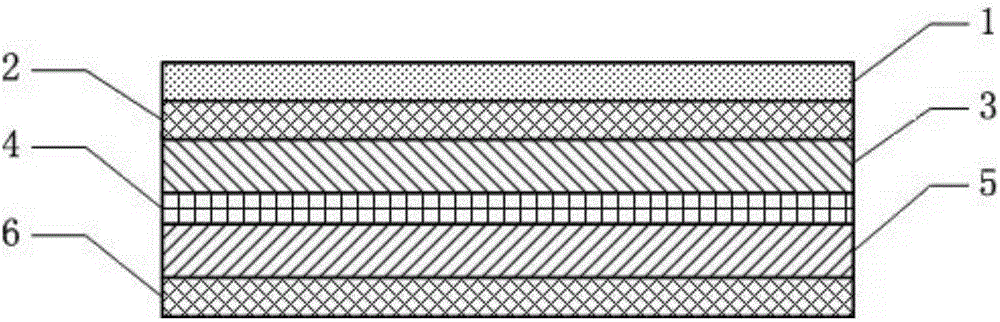

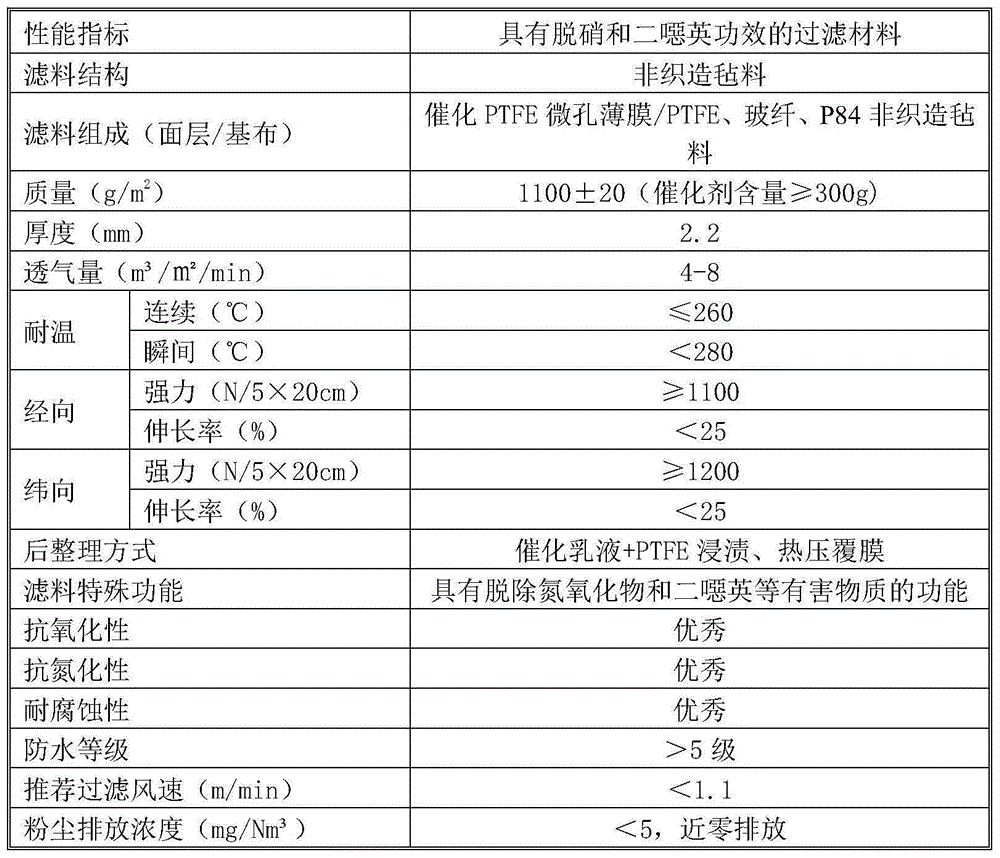

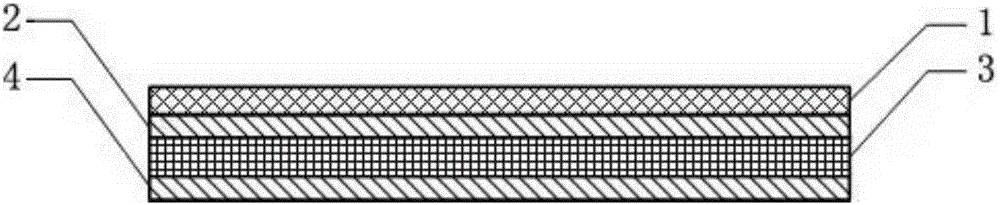

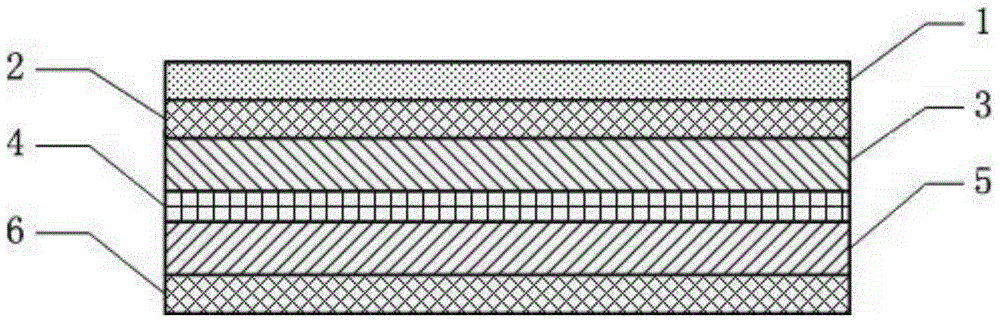

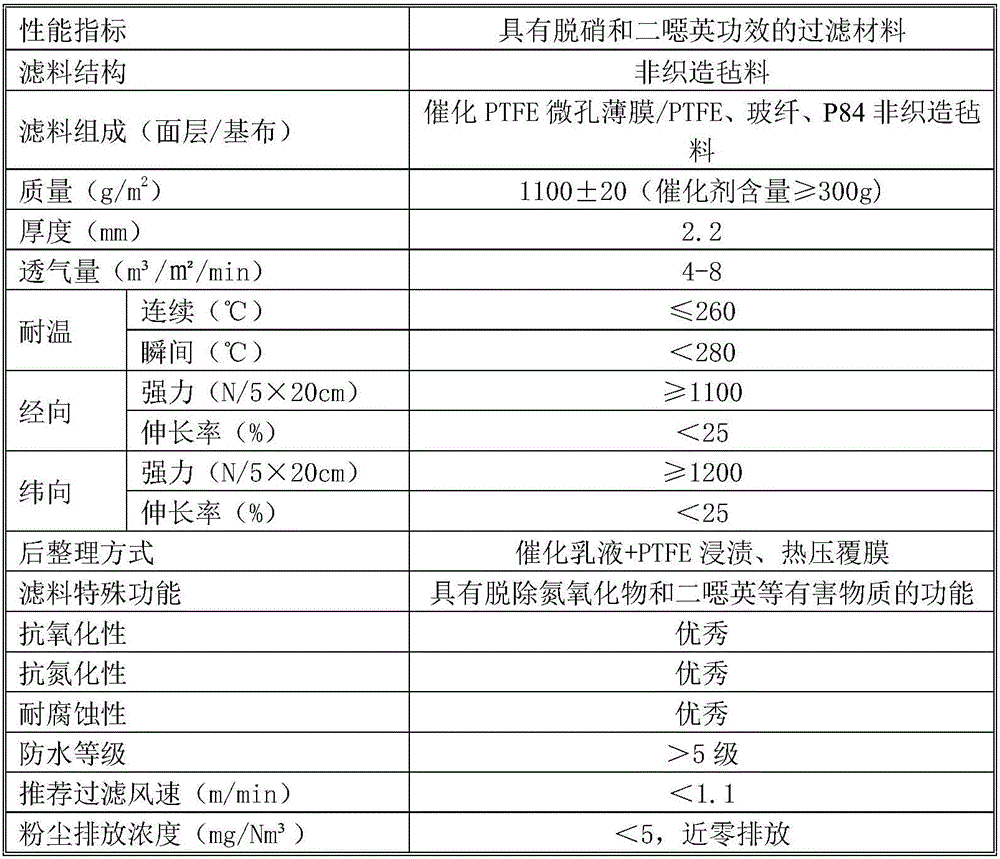

Filter material with denitration and dioxin-removal effects and preparation method thereof

ActiveCN104998467AApplicable to a wide range of working conditionsReduce consumption costsDispersed particle filtrationSynthetic resin layered productsEmulsionFiltration

The invention provides a preparation method of a filter material with denitration and dioxin-removal effects. The preparation method comprises the following steps: (1) after an active metal catalyst powder and PTFE resin powder are mixed, catalyst-containing PTFE fiber and a catalyst-containing PTFE micro-porous membrane are respectively prepared; (2) the catalyst-containing PTFE fiber and high-strength PTFE fiber are made into warp beams by a 1-10:1-10 alternate arrangement mode, and a PTFE base cloth layer is prepared by a weaving mode; (3) the catalyst-containing PTFE short fiber and a base material undergo composite acupuncture or spunlace on the surface of the PTFE base cloth layer so as to prepare a PTFE felt layer; (4) an active metal catalyst emulsion and a PTFE emulsion are mixed to prepare a catalyst mixed treating fluid, and the PTFE felt layer undergoes mass-impregnation treatment and then is sintered at 300-350 DEG C; and (5) the sintered PTFE felt layer and the catalyst-containing PTFE micro-porous membrane are simultaneously introduced into a hot laminator to undergo surface hot-press lamination processing. According to the invention, filtration accuracy and denitration and dioxin-removal efficiency can be enhanced remarkably.

Owner:辽宁新洪源环保材料有限公司

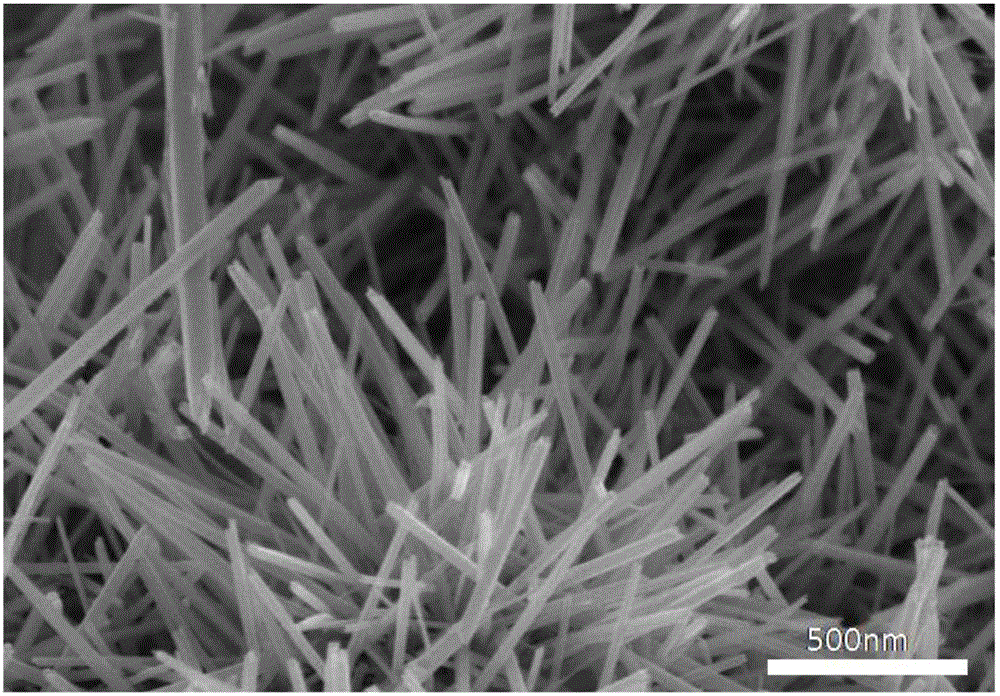

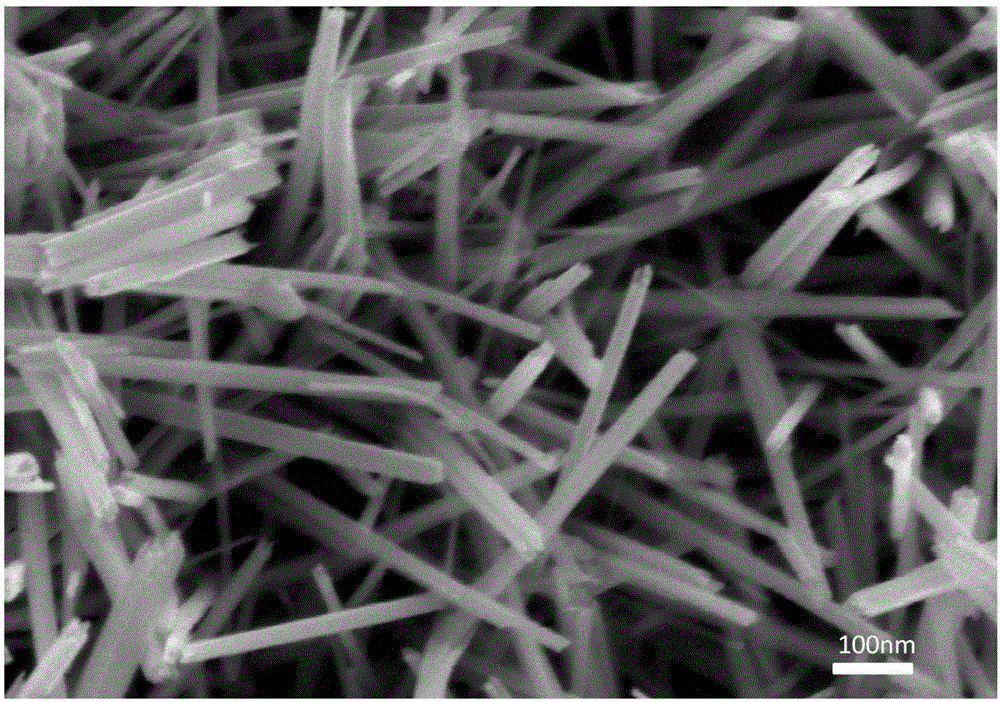

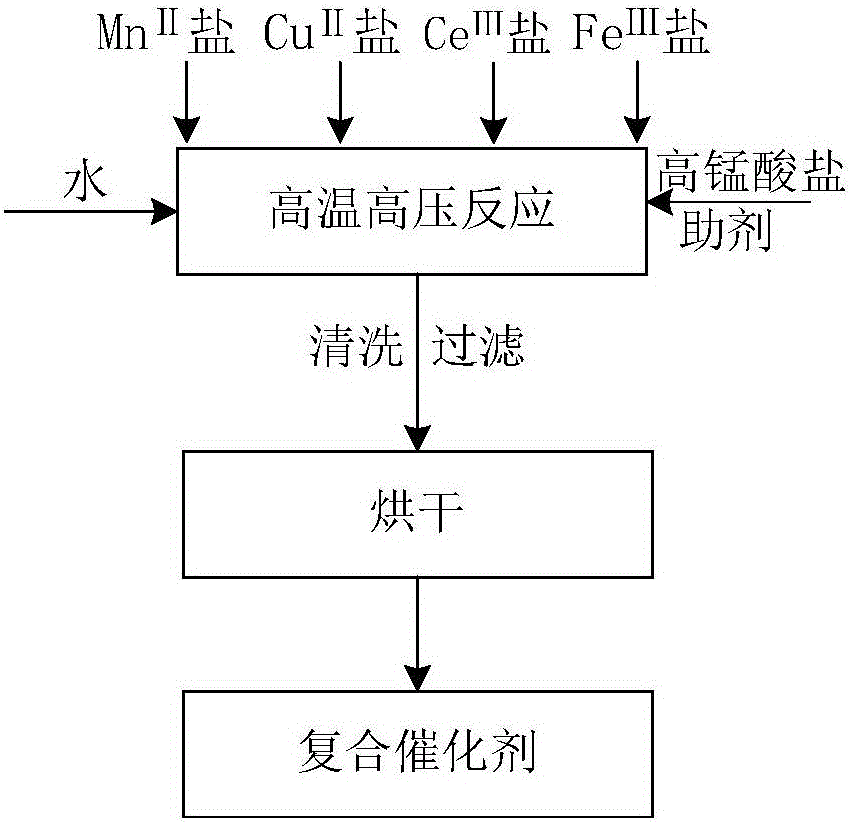

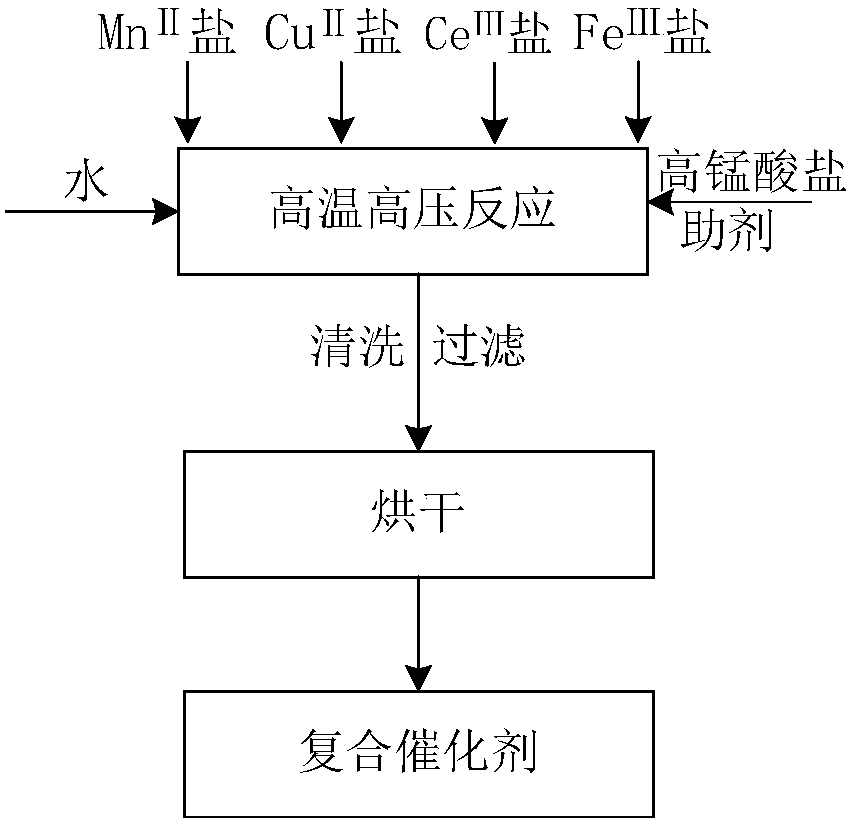

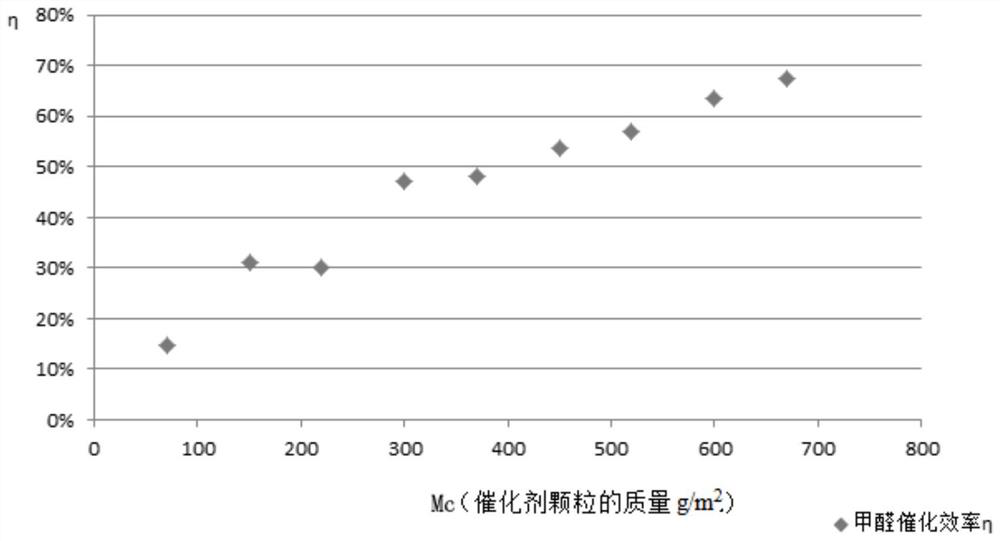

Composite catalyst for catalyzing formaldehyde decomposition and preparation method thereof

ActiveCN106238065AEasy to makeLow costHeterogenous catalyst chemical elementsDispersed particle separationRoom temperatureCatalytic decomposition

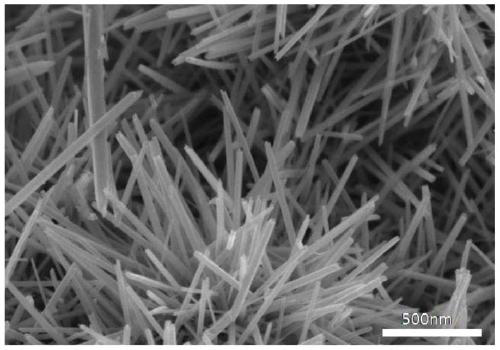

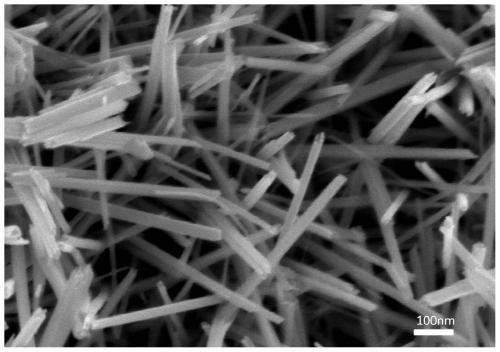

A composite catalyst for catalyzing formaldehyde decomposition and a preparation method thereof are disclosed. The preparation method comprises the following steps: successively dissolving permanganate, MnII salt, CuII salt, FeIII salt and CeIII salt in a solvent to obtain a primary mixed liquor, adding a proper amount of an auxiliary agent to obtain a secondary mixed liquor, letting the secondary mixed liquor react at high temperature and at high pressure, cleaning, filtering, and drying. The composite catalyst for catalyzing formaldehyde decomposition is nano-scale rodlike, and diameter is 10 nm. The preparation process of the composite catalyst is simple; and cost is low. The prepared composite catalyst has advantages of full doping of materials and high catalytic decomposition efficacy, and can spontaneously catalyze formaldehyde decomposition under the condition of room temperature.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

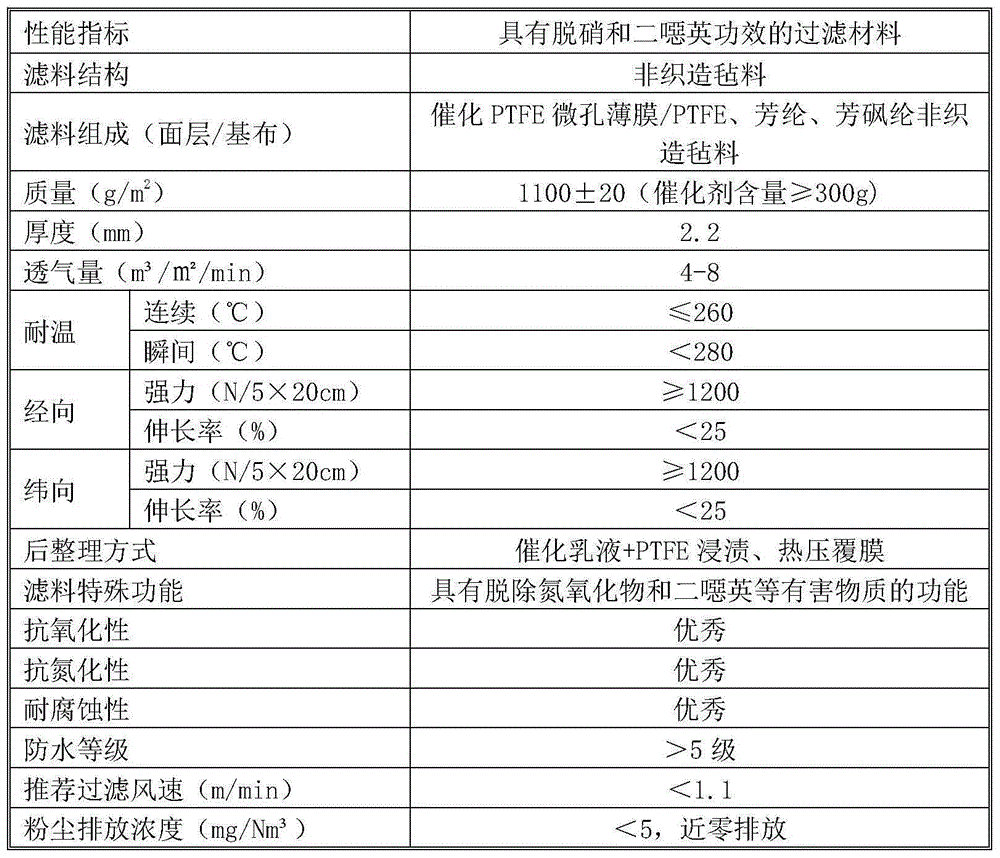

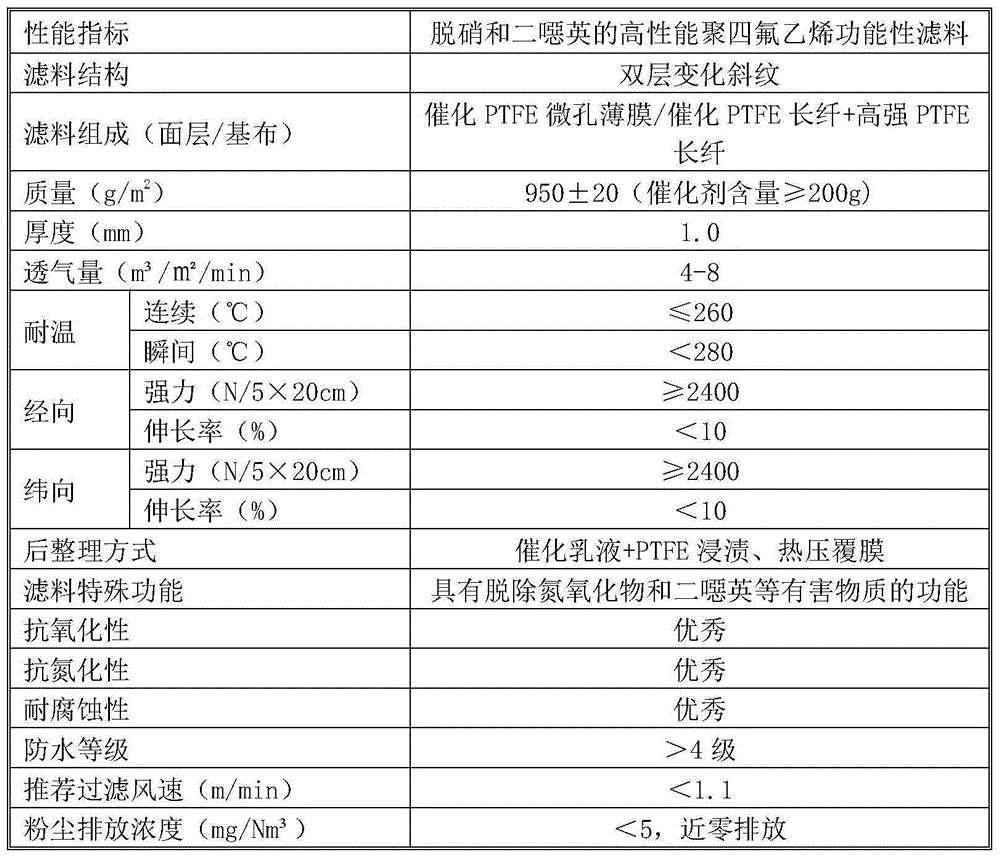

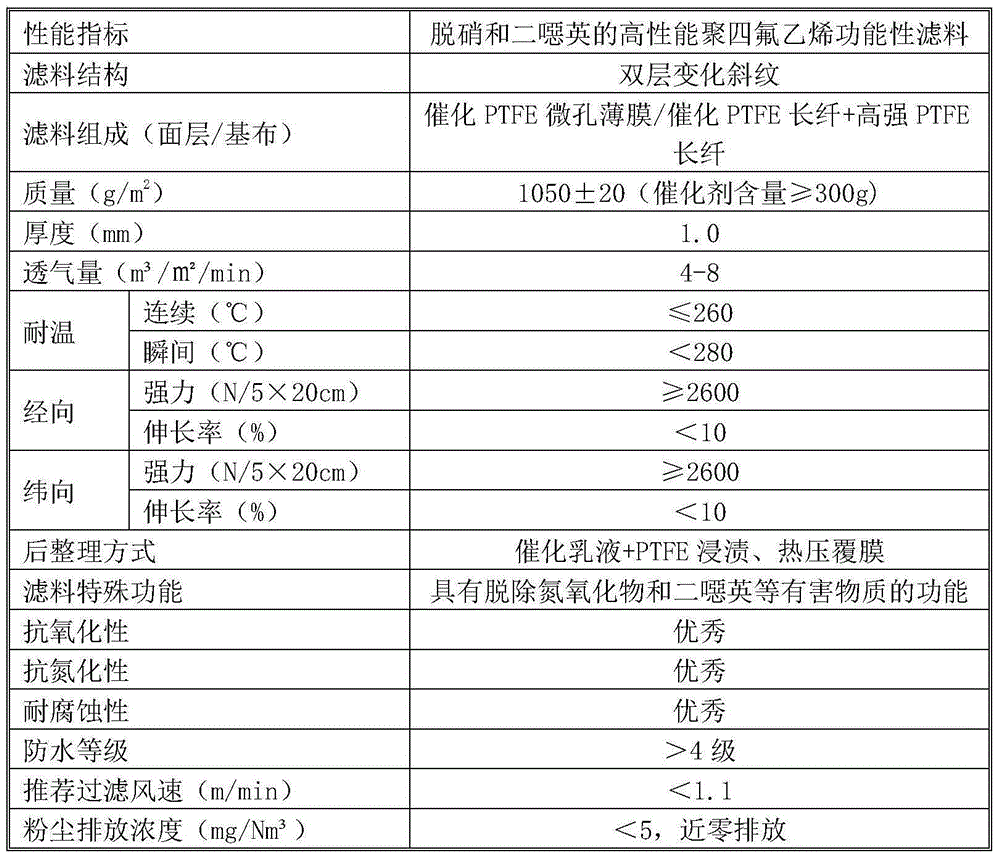

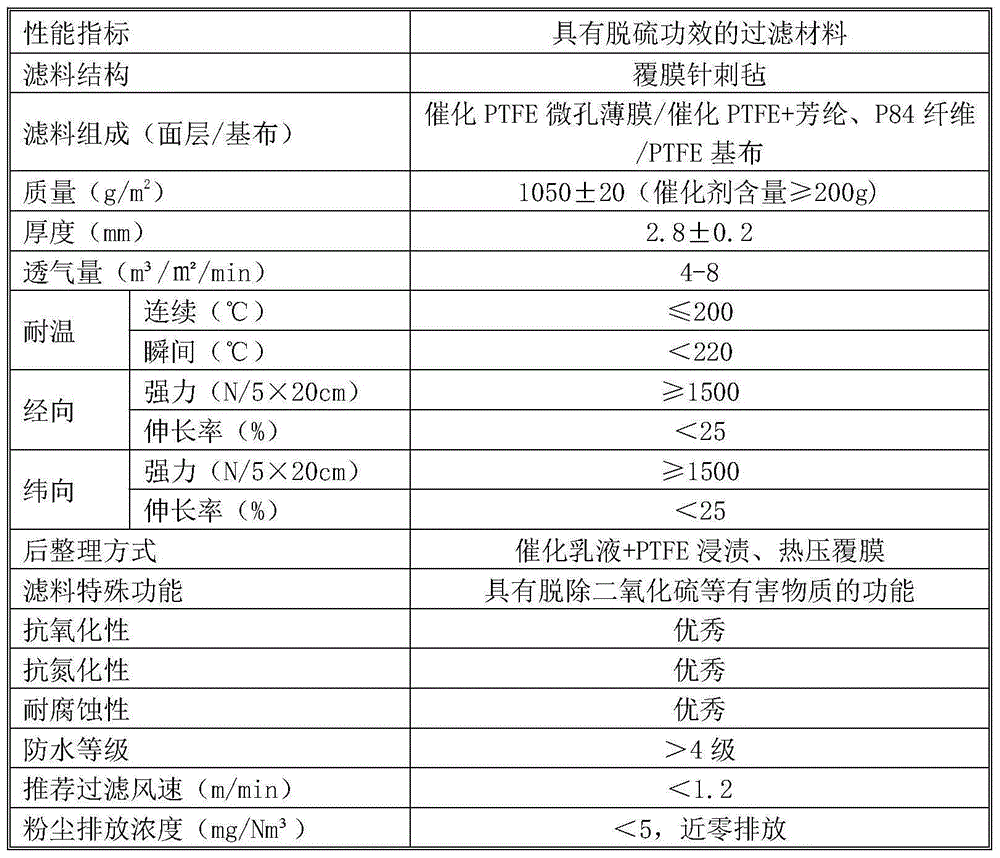

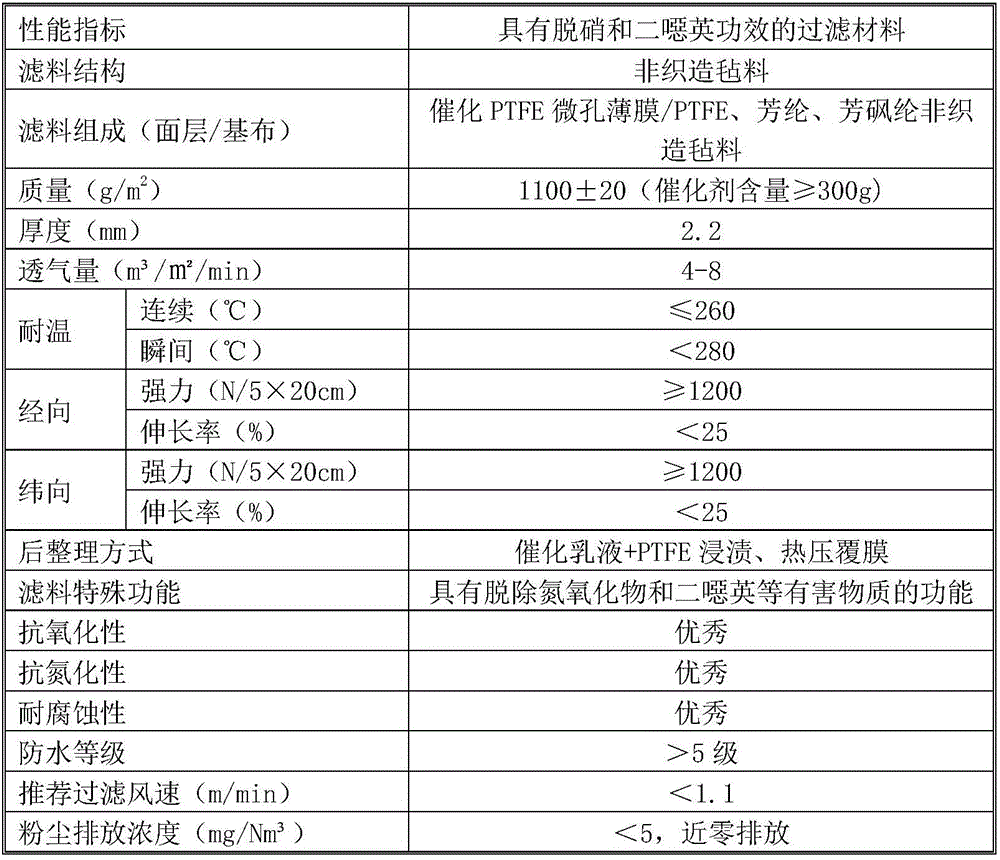

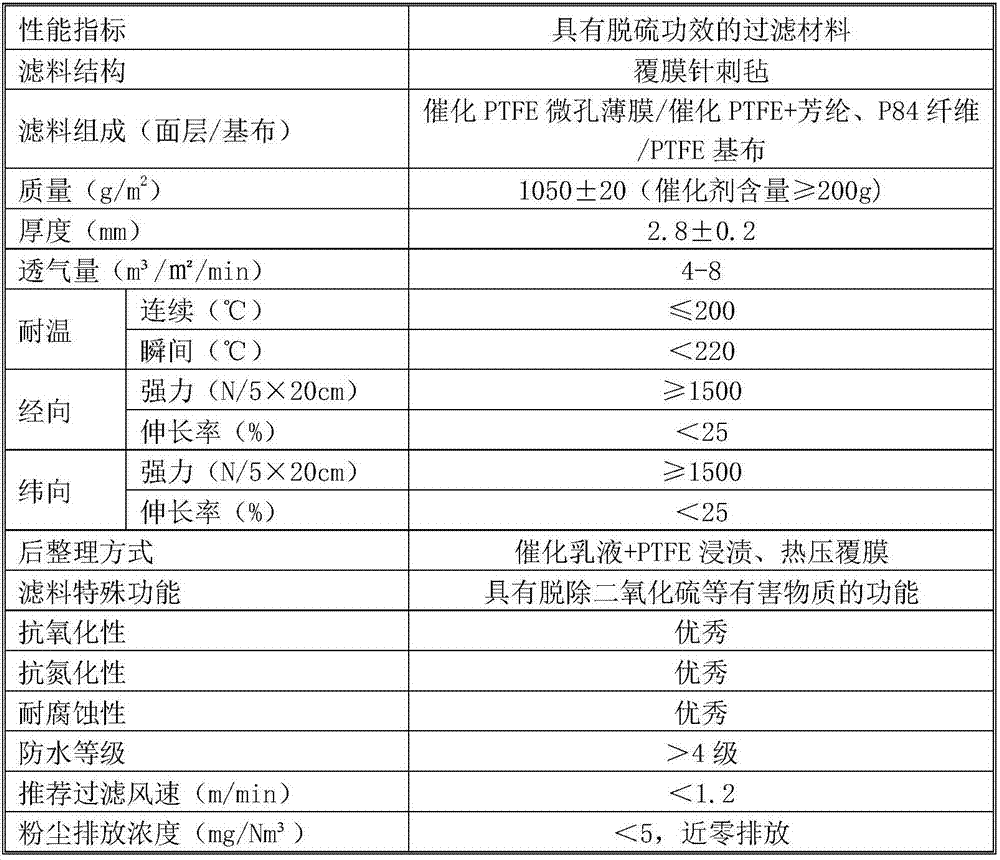

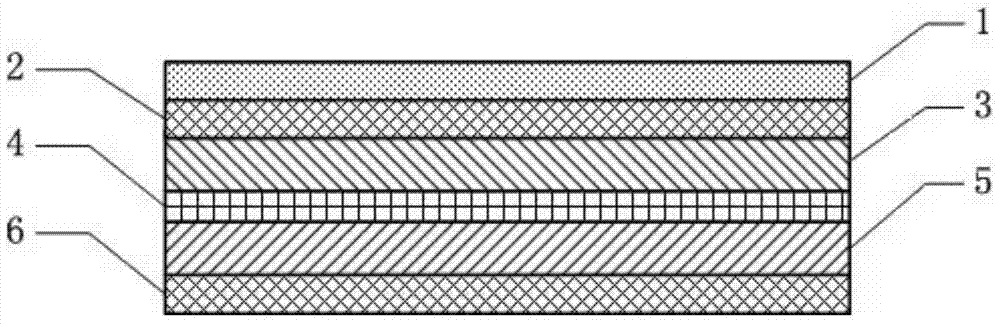

High performance polytetrafluoroethylene functional filter material for denitration and dioxin removal and preparation method thereof

ActiveCN105169807AApplicable to a wide range of working conditionsReduce consumption costsOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsEmulsionMetal catalyst

The invention provides a preparation method of a high performance polytetrafluoroethylene functional filter material for denitration and dioxin removal. The method includes the steps of: (1) mixing active metal catalyst powder with PTFE resin powder to make catalyst-containing PTFE fiber and a catalyst-containing PTFE microporous film respectively; (2) making the catalyst-containing PTFE fiber and high strength PTFE fiber into a warp beam by means of 1-10:1-10 alternate arrangement, and making a PTFE base cloth layer by machine weaving; (3) mixing an active metal catalyst emulsion with a PTFE emulsion to prepare a catalyst mixed treatment solution, conducting overall impregnation treatment on the PTFE base cloth layer, and then performing sintering at 300-350DEG C; and (4) introducing the sintered PTFE base cloth layer and the catalyst-containing PTFE microporous film into a hot film laminator simultaneously, and carrying out hot pressing laminating processing. The high performance polytetrafluoroethylene functional filter material provided by the invention can significantly improve the filtering precision and the efficiency of denitration and dioxin removal.

Owner:辽宁新洪源环保材料有限公司

Harmless decomposition method for chlorine absorption product NaClO

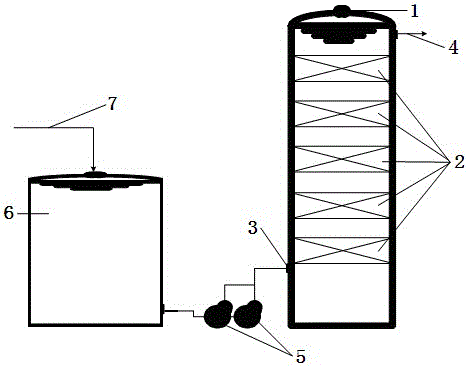

InactiveCN105800706AImprove catalytic decomposition efficiencyPlay a synergistic roleGas treatmentWater contaminantsLiquid wasteLiquid storage tank

The invention relates to a harmless decomposition method for chlorine absorption product NaClO. At present, a method capable of really realizing efficient harmless decomposition of the chlorine absorption product NaClO does not exist. Equipment used in the invention comprises a NaClO decomposition tower, a flow control pump and a liquid storage tank, wherein a catalyst tower plate in the NaClO decomposition tower is filled with a catalyst, the catalyst is formed by mixing manganese dioxide and a synergist in any proportion, and the synergist is one or more than two of copper oxide, iron oxide, nickel oxide and cobalt oxide. The method comprises the following steps: enabling tail gas containing chlorine to enter the liquid storage tank and be absorbed by absorption liquid in the liquid storage tank, so that sodium hypochlorite waste liquor is generated, transporting the sodium hypochlorite waste liquor in the liquid storage tank into the NaClO decomposition tower, enabling the sodium hypochlorite waste liquor to pass through the catalyst tower plate layer by layer from bottom to top to be subjected to catalytic decomposition reaction with the catalyst, so that waste water with the sodium hypochlorite content reaching the standard is generated, and discharging the waste water. The harmless decomposition method provided by the invention can really realize efficient harmless decomposition.

Owner:浙江钛合工程技术有限公司

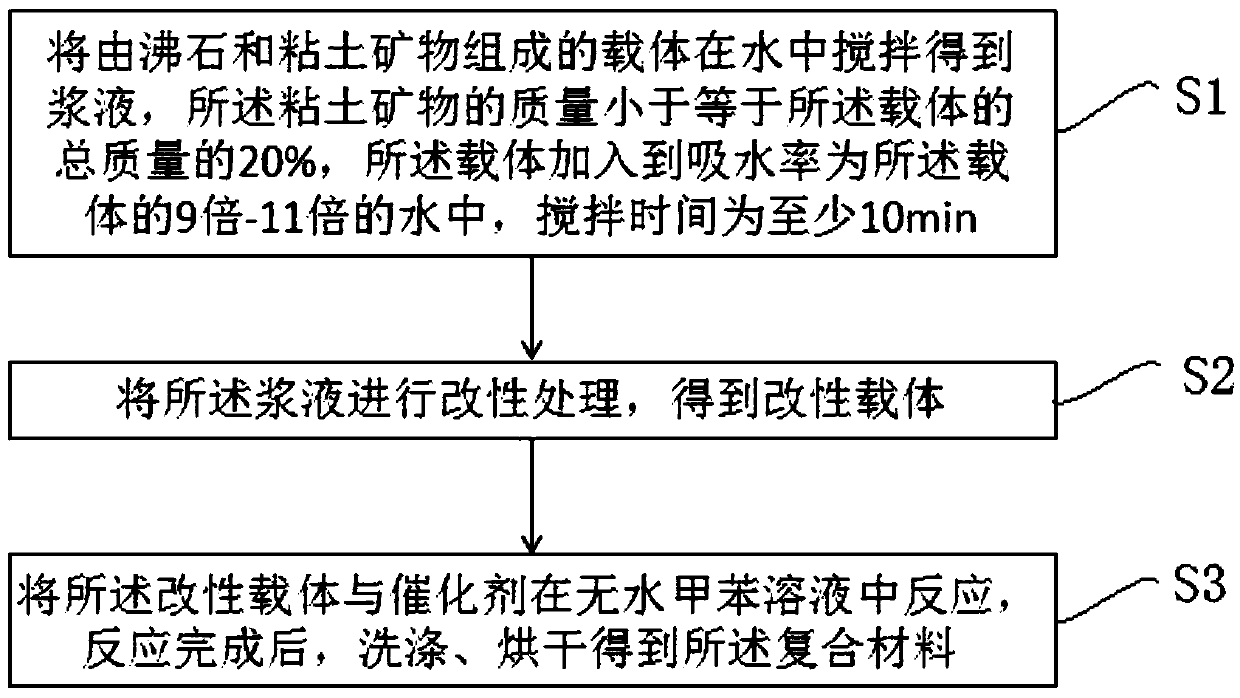

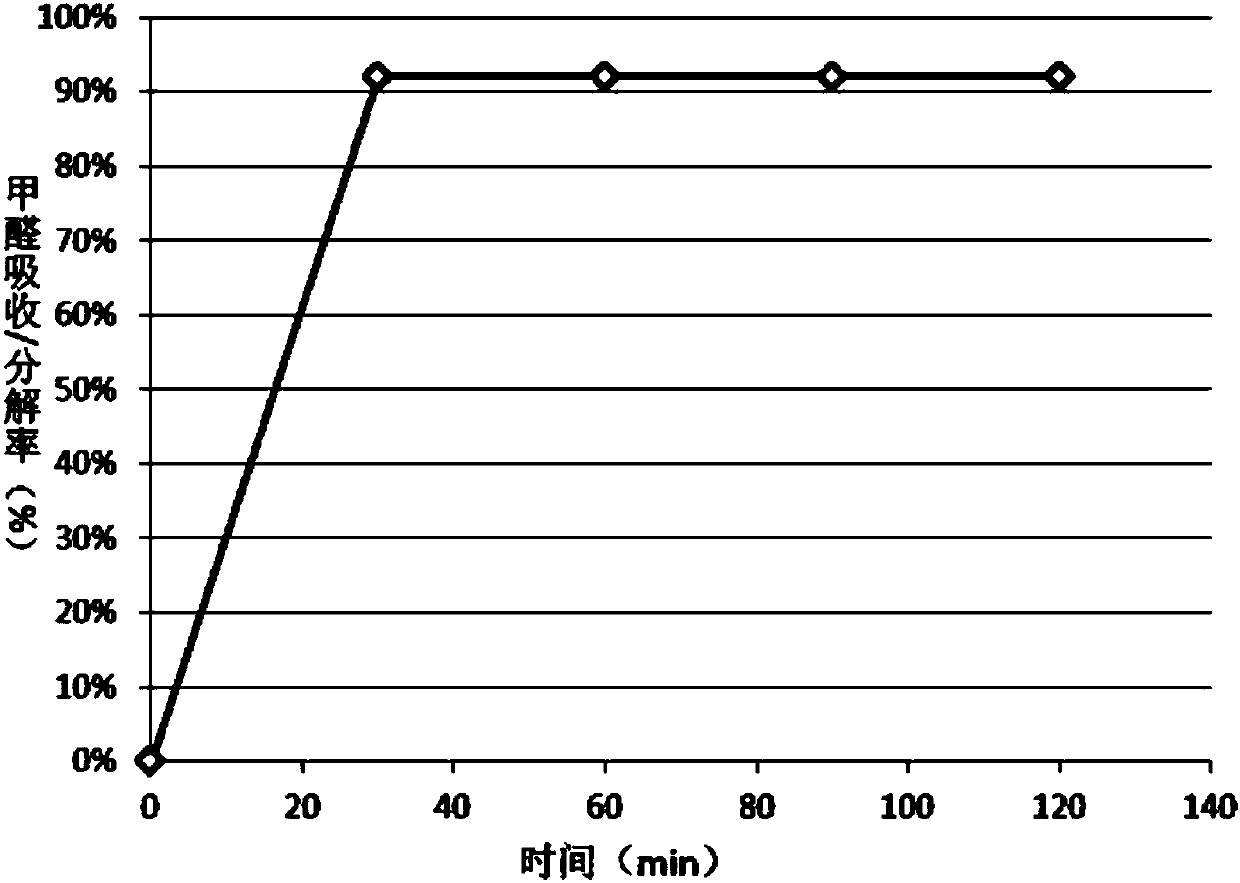

Composite material for catalyzing formaldehyde decomposition and preparation method thereof

InactiveCN107552084AAbsorptiveNon-existent problemMolecular sieve catalystsOther chemical processesClay mineralsDecomposition

The invention provides a composite material for catalyzing formaldehyde decomposition and a preparation method thereof. The preparation method of the composite material for catalyzing the formaldehydedecomposition comprises the following steps: S1, stirring a carrier comprising zeolite and clay mineral in water to obtain a slurry, wherein the mass of the clay mineral is lower than or equal to 20%of the total mass of the carrier, the carrier is added into water of which the water absorption is 9-11 times of that of the carrier, and the stirring time is at least 10min; S2, modifying the slurryto obtain a modified carrier; S3, performing a reaction on the modified carrier and a catalyst in an anhydrous toluene solution, and after the reaction, washing and drying to obtain the composite material. According to the preparation method of the composite material for catalyzing the formaldehyde decomposition, provided by the embodiment of the invention, raw materials are easy to obtain, the preparation method is simple and convenient, and the reaction is convenient to control; the composite material prepared by preparation method has high formaldehyde adsorbing capacity; the composite material can efficiently decompose formaldehyde without additional energy delivery.

Owner:江苏龙商环保科技有限公司

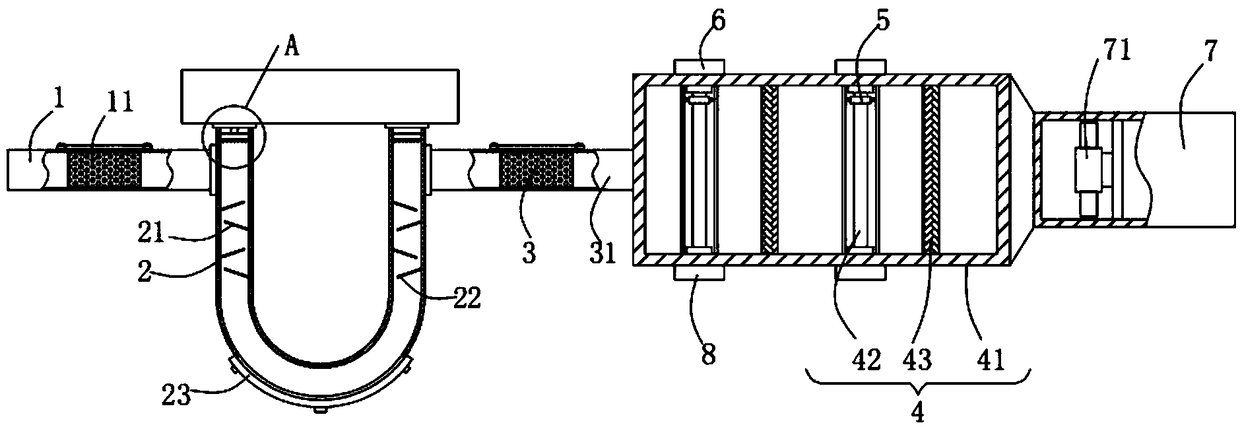

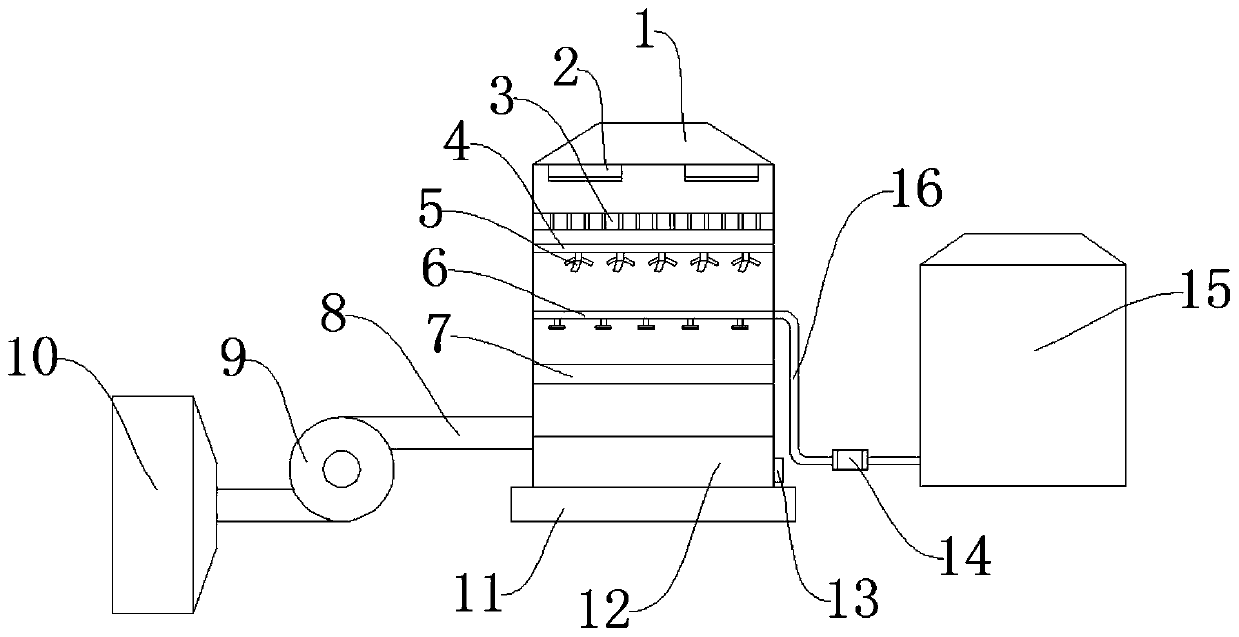

Photocatalytic decomposition purification system for organic waste gas

PendingCN109276968ASpeed up circulationImprove filtering effectCombination devicesGas treatmentFiltrationFlue gas

The invention relates to the field of air purification technology, in particular to a photocatalytic decomposition purification system for organic waste gas, comprising an air inlet pipe, a dust removal pipe, a circulation pipe, a catalysis mechanism, a cleaning mechanism, a first traction mechanism, an exhaust pipe, a second traction mechanism and a spraying mechanism. The circulation pipe of a U-shaped structure can prolong the flow speed of flue gas, so that the solid particles can gather at the bottom of the circulation pipe, and obliquely distributed first and second baffles can be used for filtering out of the solid particles, thereby further improving the filtration effect; the spraying mechanism communicating with the top of the circulation pipe can accelerate the falling speed ofthe solid particles, and can cause a neutralize reaction with the flue gas to further improve the separation effect; and the first traction mechanism and the second traction mechanism can drive the cleaning mechanism to move up and down to scrape off dirt attached to the outer wall of an ultraviolet lamp, thereby ensuring the illumination intensity of the ultraviolet lamp, and improving the catalytic decomposition efficiency.

Owner:谢响玲

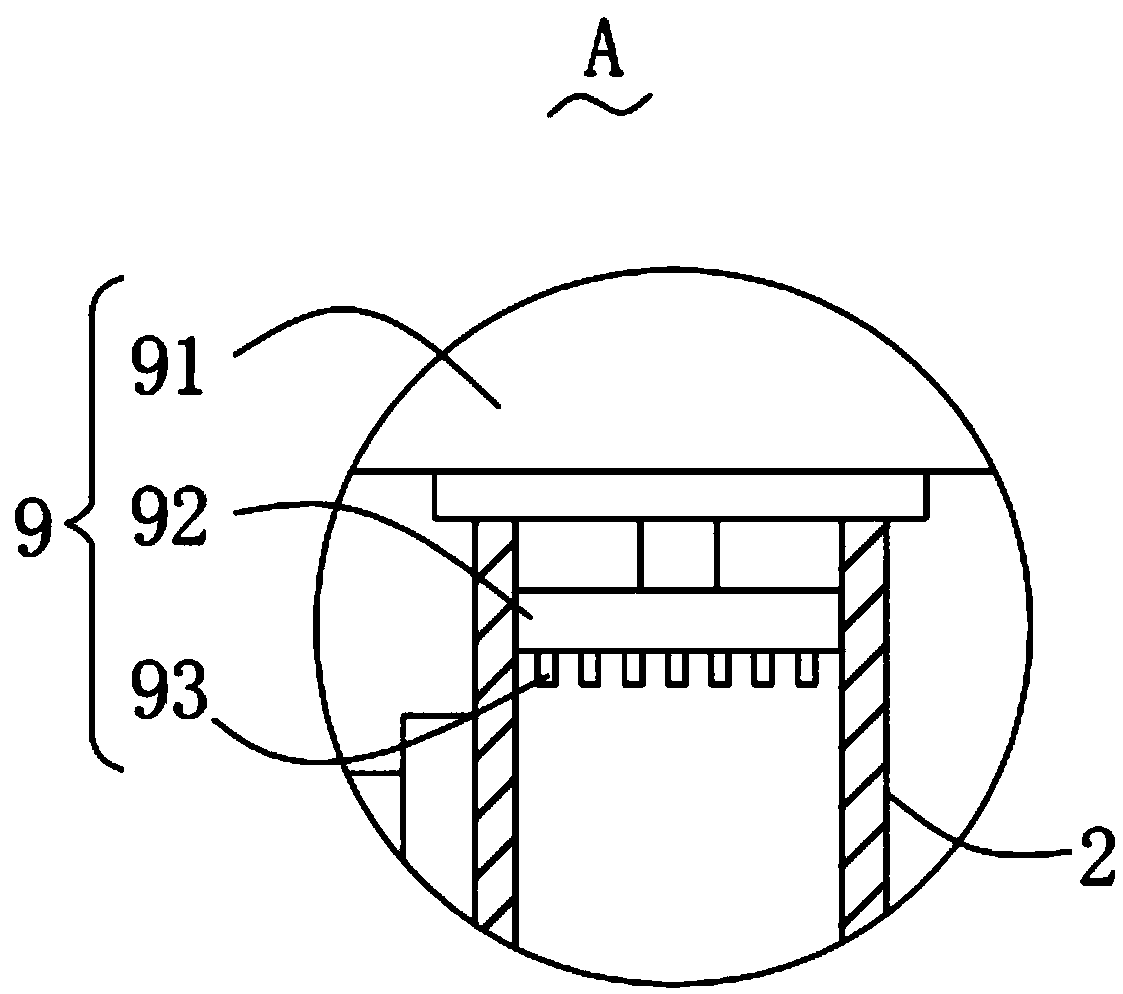

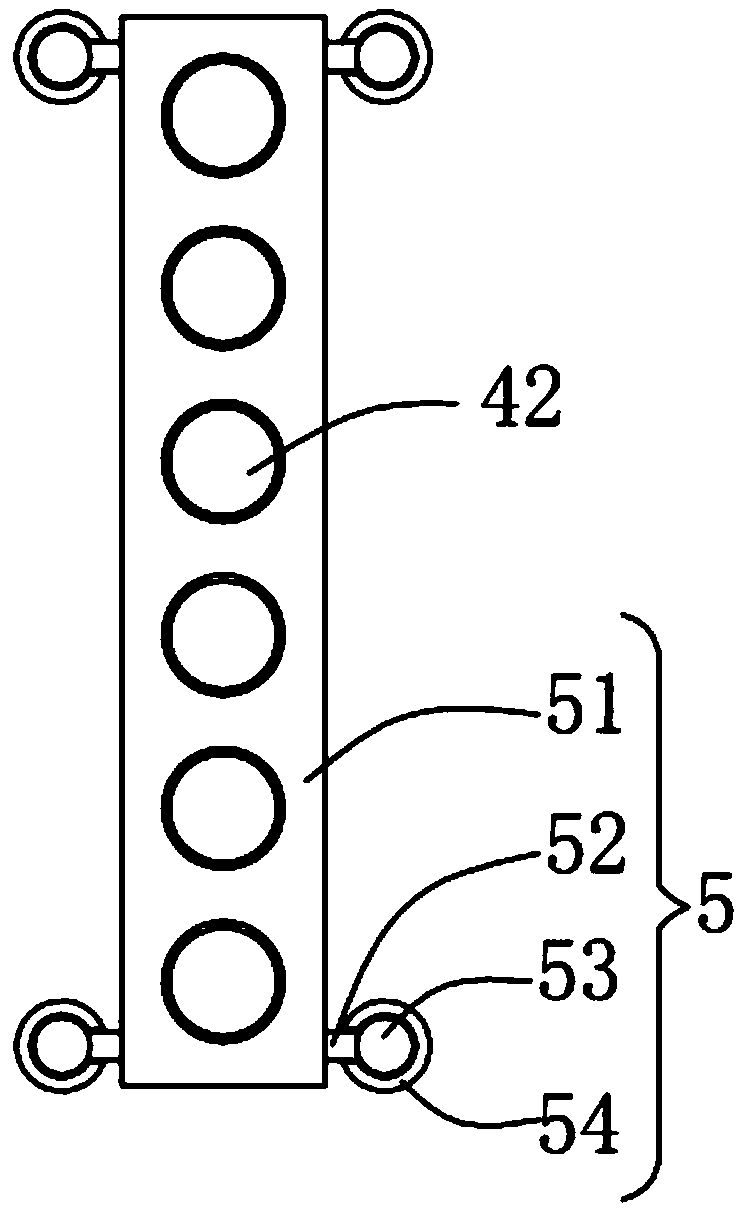

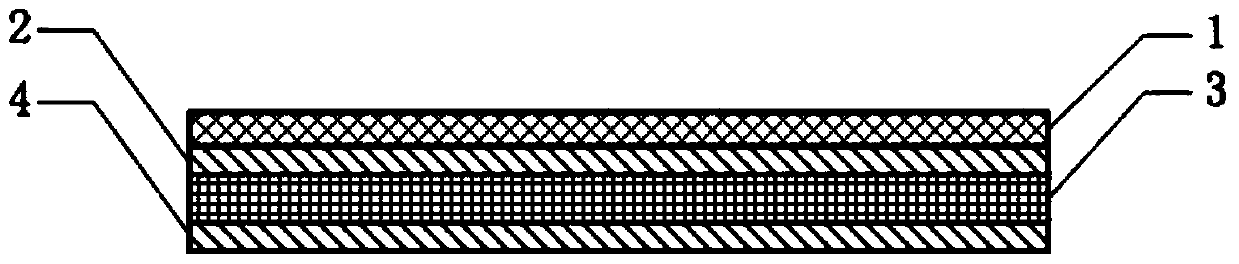

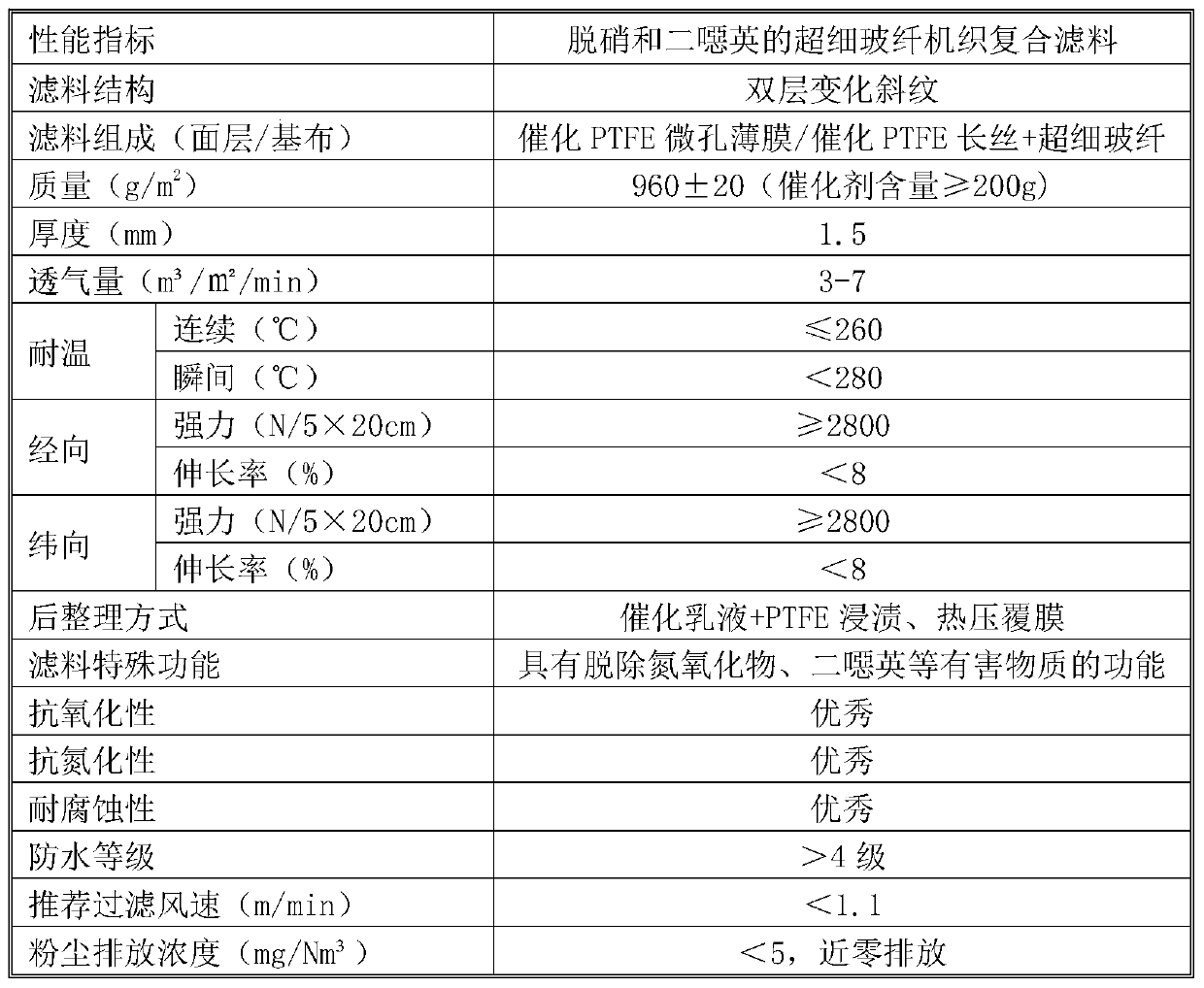

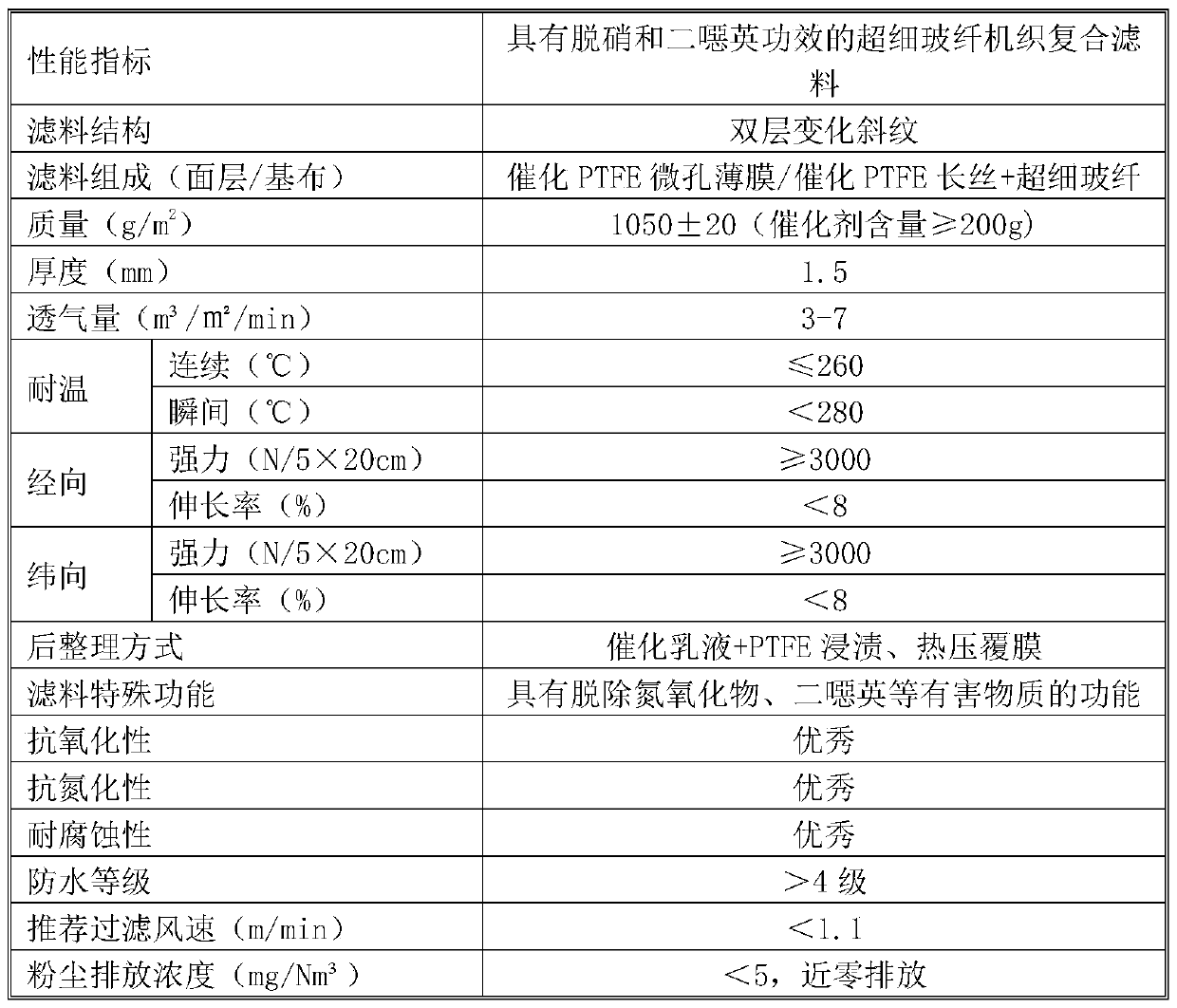

A kind of ultra-fine glass fiber woven composite functional filter material for denitrification and dioxin and preparation method thereof

ActiveCN105032034BApplicable to a wide range of working conditionsReduce consumption costsOrganic-compounds/hydrides/coordination-complexes catalystsGlass/slag layered productsYarnFiltration

The invention provides a method for preparing an ultrafine glass fiber woven composite functional filter material for denitrification and dioxin, which comprises the following steps: (1) after mixing active metal catalyst powder and PTFE resin, respectively making catalyst-containing PTFE fibers and PTFE microporous films containing catalysts; (2) blending PTFE fibers containing catalysts with ultrafine glass fibers to make composite yarns, and weaving them into ultrafine glass fibers and catalytic PTFE fiber blending machines Weaving layer; (3) Mix the active metal catalyst emulsion and PTFE emulsion to make a mixed catalyst treatment solution, and then sinter at 300-350°C after overall impregnation of the ultrafine glass fiber and catalytic PTFE fiber blended woven fabric layer; (4) The sintered superfine glass fiber and catalytic PTFE fiber blended woven fabric layer and the PTFE microporous film containing the catalyst are simultaneously introduced into a thermal laminating machine for surface thermal pressing lamination. The invention can remarkably improve the filtration precision and the efficiency of denitrification and dioxin removal.

Owner:辽宁新洪源环保材料有限公司

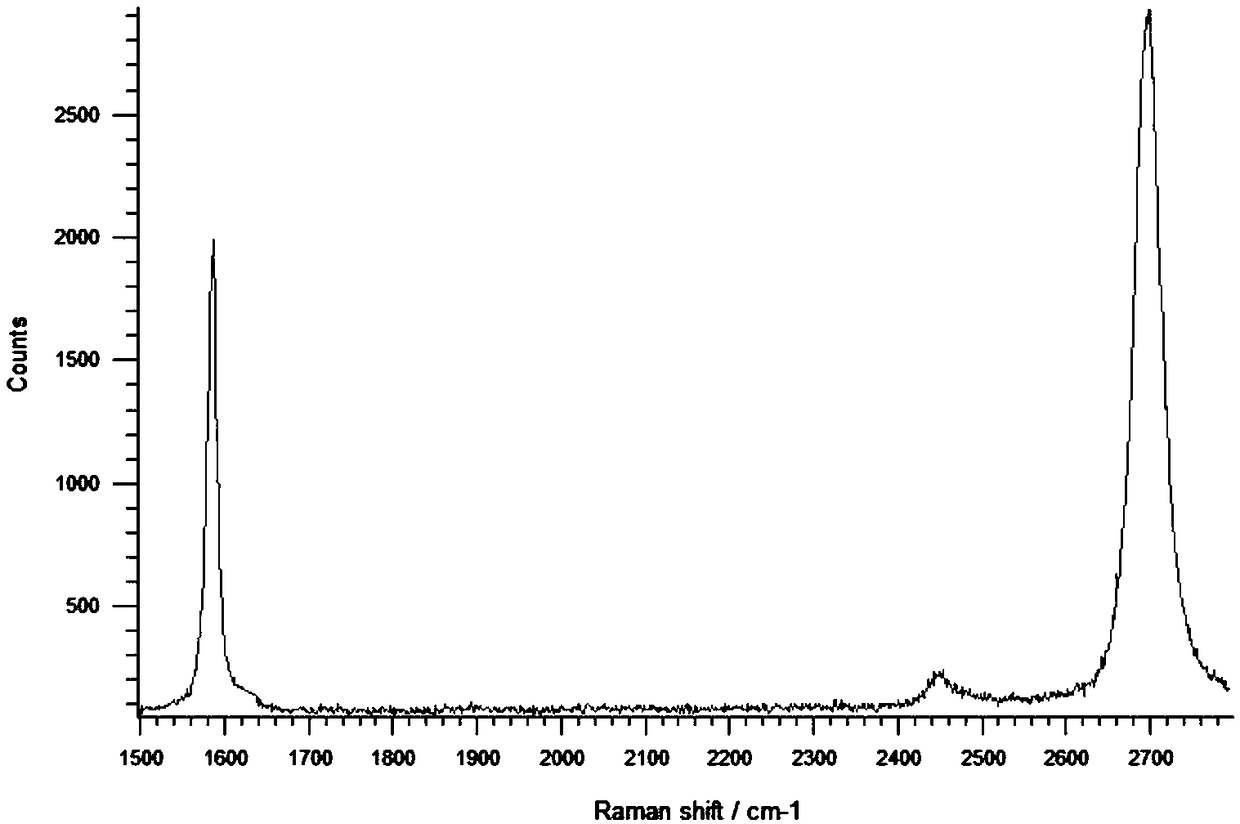

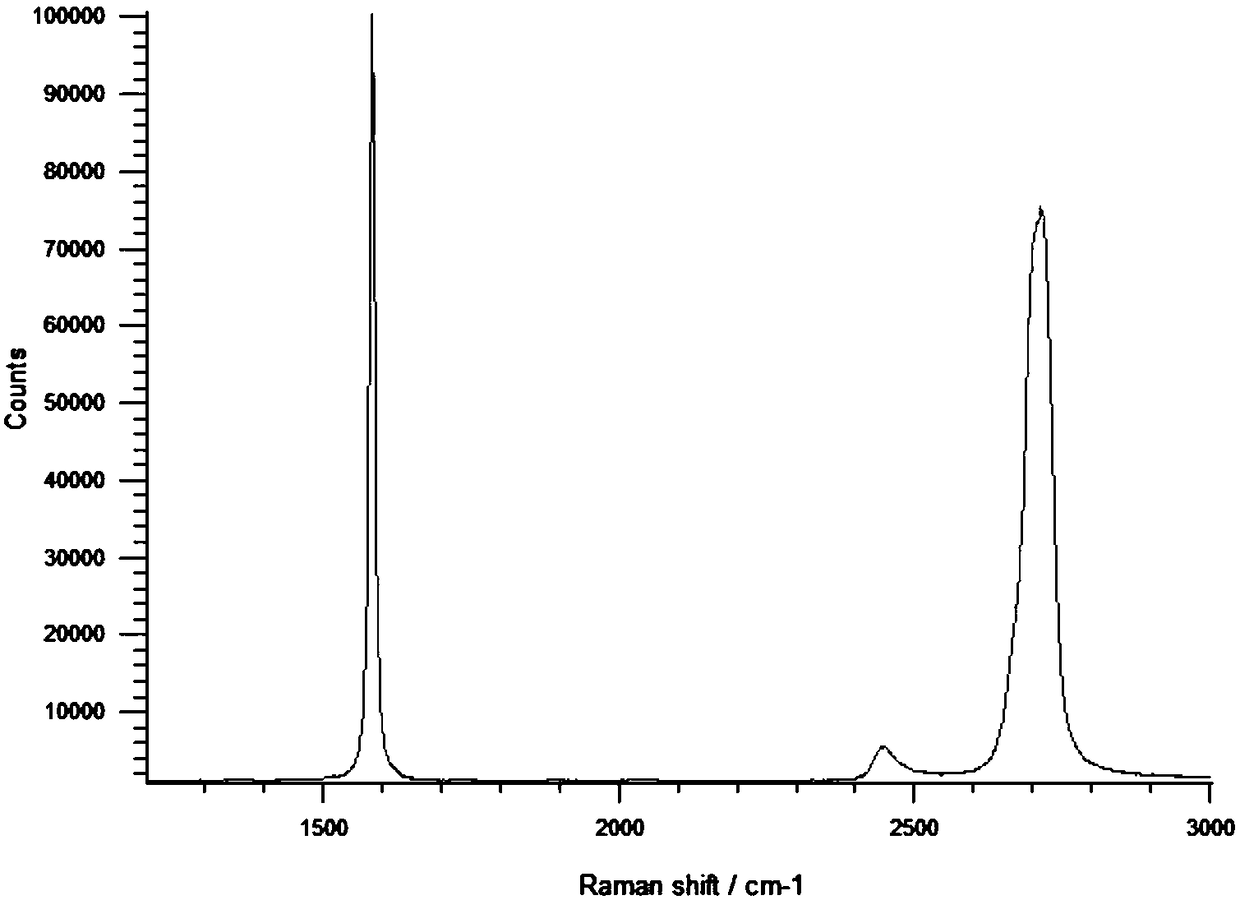

Method for growing copper-based multilayered graphene

The invention discloses a method for growing copper-based multilayered graphene. The method comprises following steps: (1) after pre-treating a copper foil substrate, putting into a bracket; (2) covering the outer surface of the bracket with one layer of metal foil; (3) putting the bracket covered with the metal foil into a vacuum system and carrying out annealing treatment; (4) introducing carbon-containing gas and reacting for 30 to 60 minutes; after cooling, forming the multilayered graphene on the surface of a copper foil. According to the method disclosed by the invention, the copper-based graphene grows by adopting a low-pressure vapor phase deposition method, the safety is good and the growth speed is high; the outer surface of the bracket is covered with one layer of the metal foilso that the catalytic decomposition efficiency of the carbon-containing gas can be improved and the concentration of carbon atoms is increased; meanwhile, the evaporation of the copper foil substrateis inhibited and the multilayered graphene is easy to form. The method disclosed by the invention is simple and easy to operate; the outer-layer coated metal foil can be repeatedly utilized and additional energy consumption is not increased; the high-quality and high-multilayer-rate graphene can be formed.

Owner:WUXI HUICHENG GRAPHITE ALKENE TECH APPL CO LTD

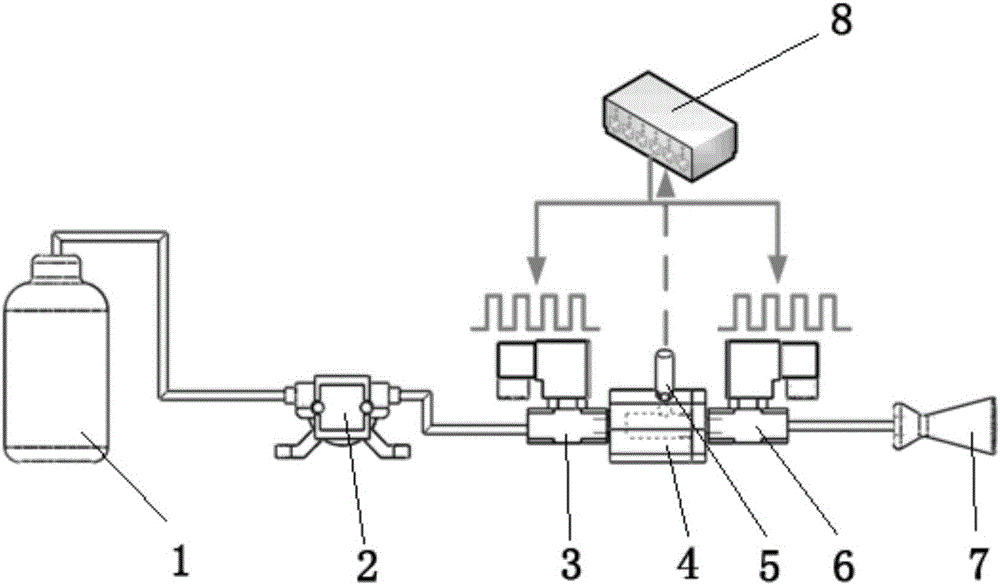

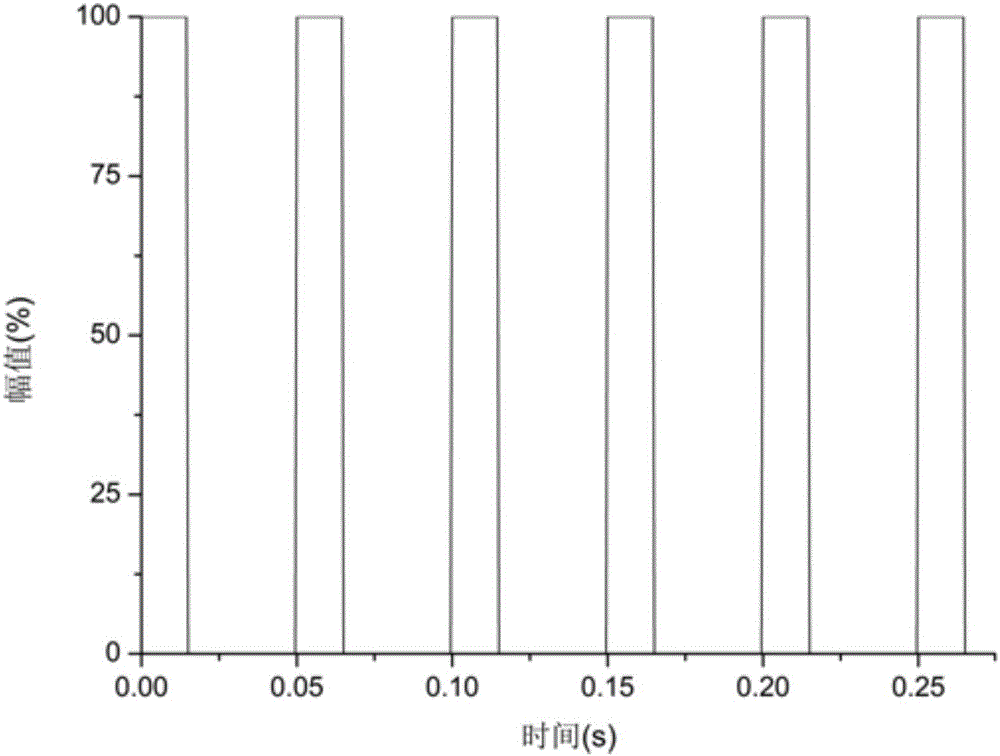

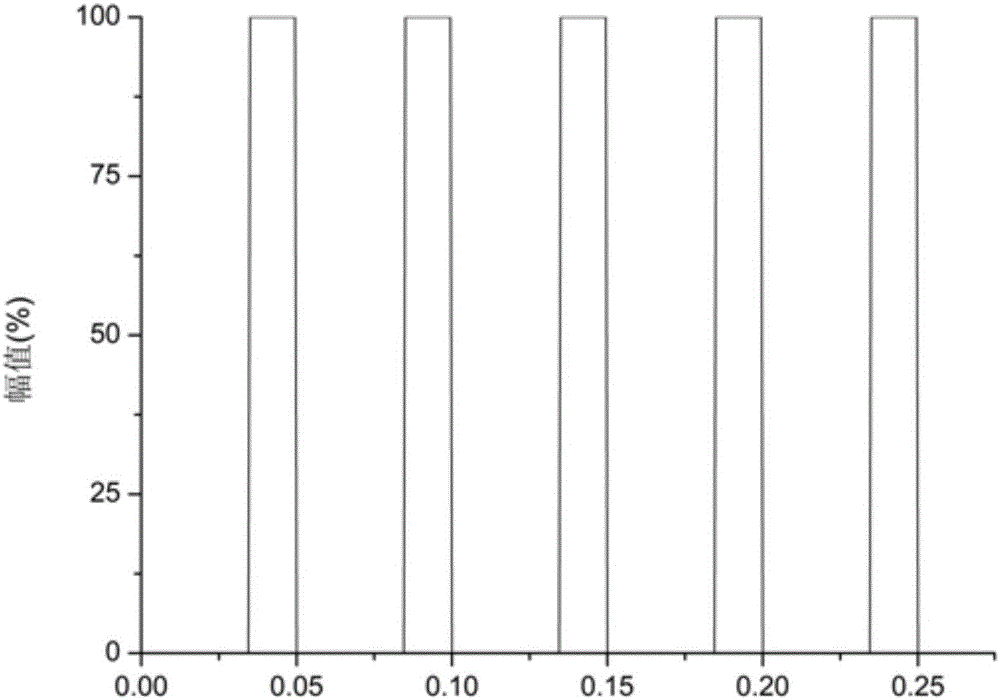

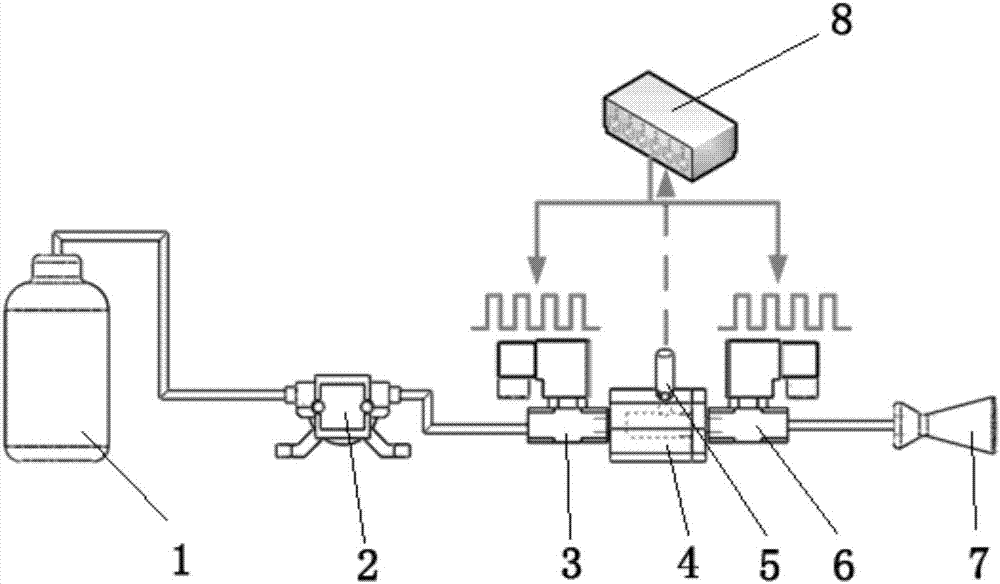

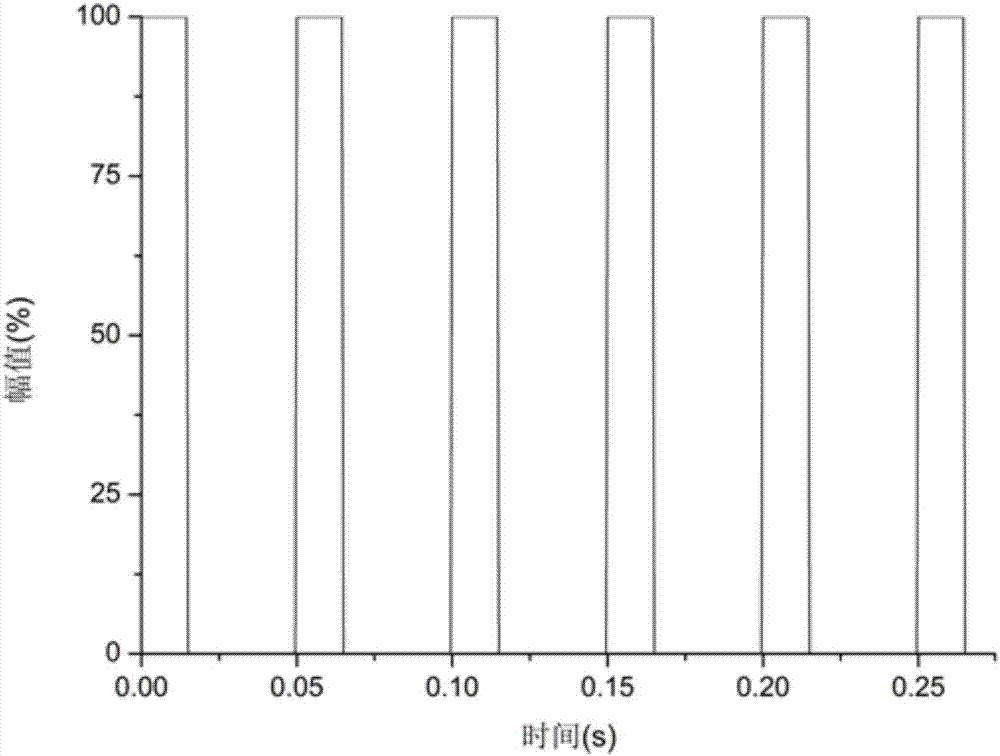

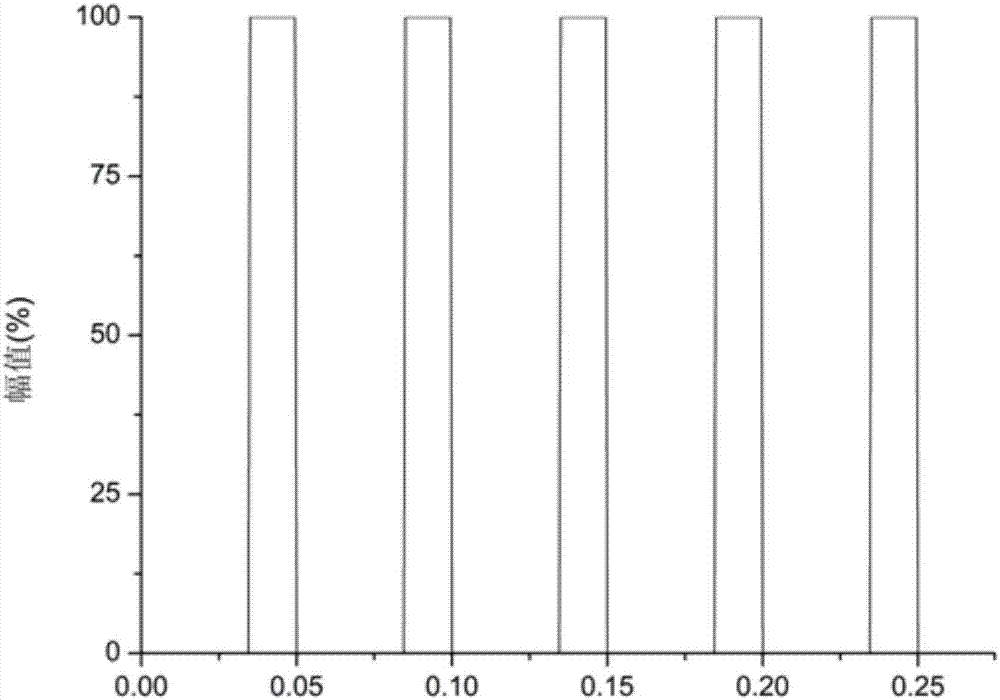

Impulse-type bionic power device based on single-component fuel and control method thereof

InactiveCN105977511ALower activation energyImprove power densityReactant parameters controlExoskeleton robotControl signal

The invention provides an impulse-type bionic power device based on a single-component fuel. The device mainly consists of a fuel supply system and an impulse-type reaction system, wherein the fuel supply system is used for realizing storage and flow regulation and control of single-component fuels; the single-component fuels sequentially pass through an inlet high-frequency switch valve and a catalyst bed of the impulse-type reaction system and are decomposed from a liquid state into a gas state under the action of a catalyst, so that the internal pressure of the catalyst bed increases rapidly; the whole process can be divided into three stages, namely an input stage, a reaction stage and a spraying stage; during the input stage, the inlet high-frequency switch valve is opened, and an outlet high-frequency switch valve is closed; during the reaction stage, the inlet high-frequency switch valve and the outlet high-frequency switch valve are closed; during the spraying stage, the outlet high-frequency switch valve is opened, and the inlet high-frequency switch valve is closed. The device is capable of obtaining the flow of a flow pump and parameter values such as PWM control signal duty ratio of the inlet high-frequency switch valve and the outlet high-frequency switch valve by use of formulae of thermodynamics and hydromechanics according to the output force requirement, and generating a continuous impulse spraying effect. The impulse-type bionic power device has the advantages of high power density, environmental friendliness, simple structure, high efficiency and the like, and is applicable to power systems of devices such as exoskeleton robots and jet packs.

Owner:NAT UNIV OF DEFENSE TECH

A kind of composite catalyst for catalyzing the decomposition of formaldehyde and preparation method thereof

ActiveCN106238065BEasy to makeLow costHeterogenous catalyst chemical elementsDispersed particle separationRoom temperatureCatalytic decomposition

A composite catalyst for catalyzing formaldehyde decomposition and a preparation method thereof are disclosed. The preparation method comprises the following steps: successively dissolving permanganate, MnII salt, CuII salt, FeIII salt and CeIII salt in a solvent to obtain a primary mixed liquor, adding a proper amount of an auxiliary agent to obtain a secondary mixed liquor, letting the secondary mixed liquor react at high temperature and at high pressure, cleaning, filtering, and drying. The composite catalyst for catalyzing formaldehyde decomposition is nano-scale rodlike, and diameter is 10 nm. The preparation process of the composite catalyst is simple; and cost is low. The prepared composite catalyst has advantages of full doping of materials and high catalytic decomposition efficacy, and can spontaneously catalyze formaldehyde decomposition under the condition of room temperature.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

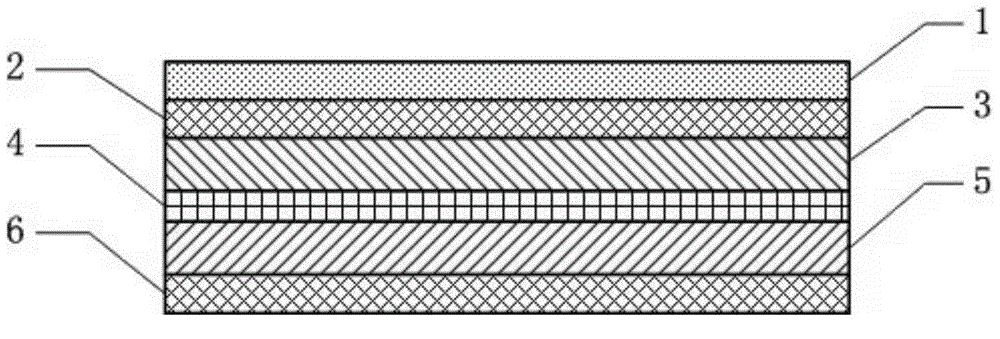

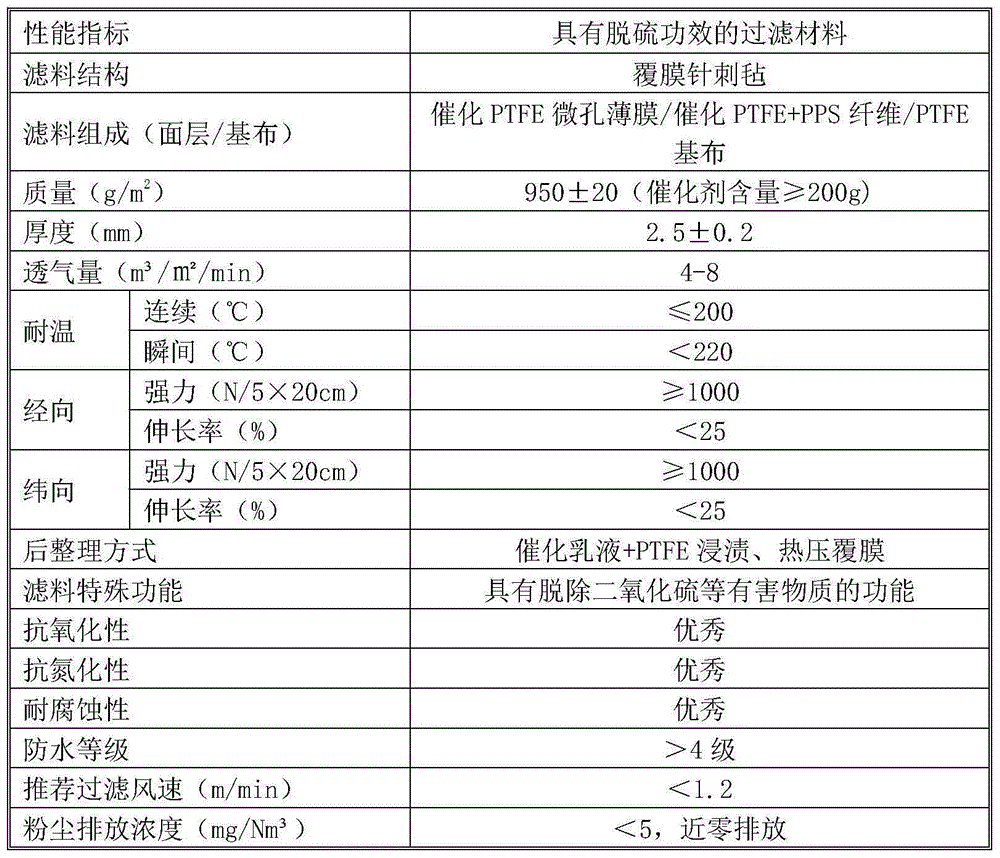

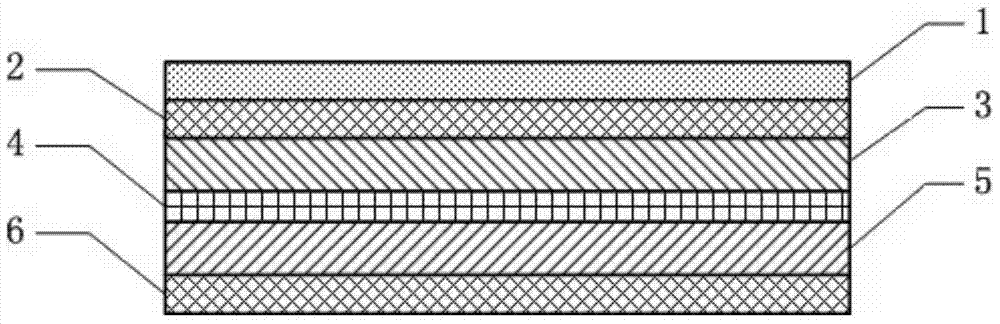

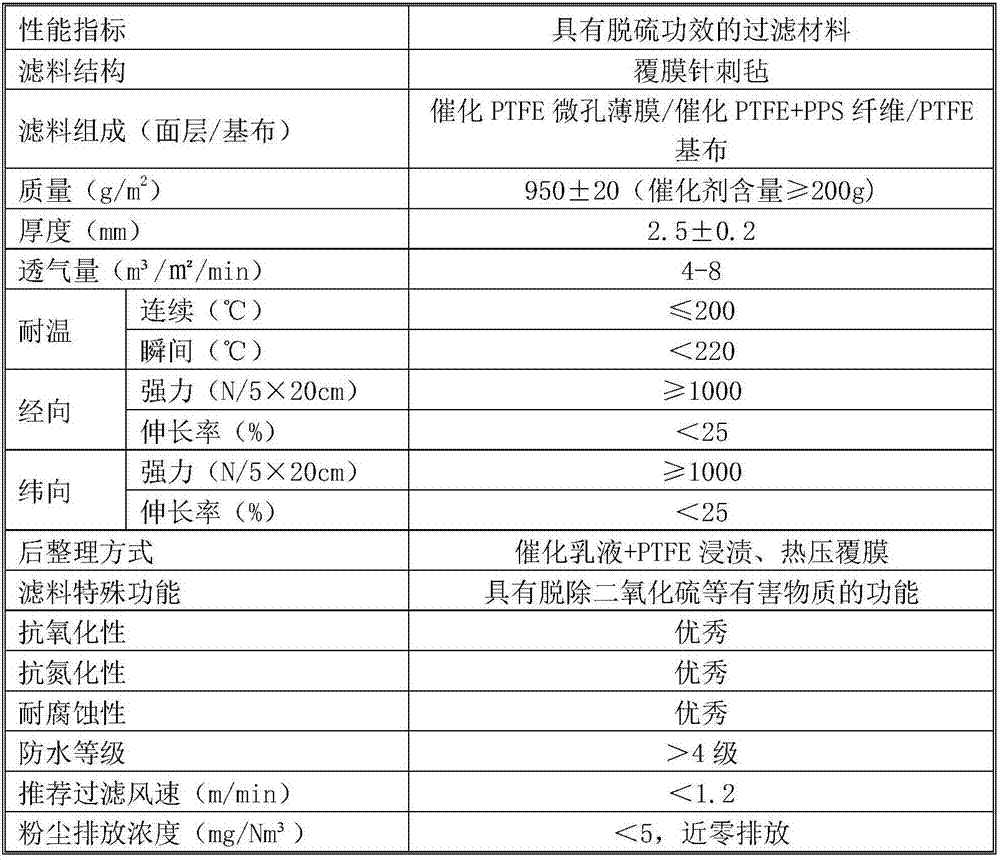

Filtering material possessing desulphurization efficacy and preparation method thereof

ActiveCN105013250AApplicable to a wide range of working conditionsReduce consumption costsDispersed particle filtrationSynthetic resin layered productsEmulsionFiltration

The invention provides a preparation method of a filtering material possessing desulphurization efficacy, which comprises the following steps: 1)active metal catalyst powder and PTFE resin powder are mixed and respectively prepared to catalyst-containing PTFE fiber and catalyst-containing PTFE micropore film; 2) catalyst-containing PTFE fiber and high-strength PTFE fiber employs an alternative arrangement mode with 1-10: 1-10 to prepare warp beam, a PTFE base cloth layer is prepared by employing a machine knitting mode; 3)the base material and catalyst-containing PTFE fiber are mixed, and then placed in a needle loom with the PTFE base cloth layer to prepare PTFE composite needled felt; 4)an active metal catalyst emulsion and a PTFE emulsion are mixed to prepare a catalyst mixing treatment fluid, the PTFE composite needled felt is performed with integral dipping treatment and sintered at temperature of 280-350 DEG C; and 5)the sintered PTFE composite needled felt and the catalyst-containing PTFE micropore film are simultaneously introduced into a heat film covering machine, and the surface is performed with hot pressing and laminating. According to the invention, filtration accuracy as well as desulphurization efficiency can be greatly increased.

Owner:辽宁新洪源环保材料有限公司

A kind of filter material with denitration and dioxin efficacy and preparation method thereof

ActiveCN104998467BApplicable to a wide range of working conditionsReduce consumption costsDispersed particle filtrationSynthetic resin layered productsEmulsionMetal catalyst

The invention provides a preparation method of a filter material with denitration and dioxin-removal effects. The preparation method comprises the following steps: (1) after an active metal catalyst powder and PTFE resin powder are mixed, catalyst-containing PTFE fiber and a catalyst-containing PTFE micro-porous membrane are respectively prepared; (2) the catalyst-containing PTFE fiber and high-strength PTFE fiber are made into warp beams by a 1-10:1-10 alternate arrangement mode, and a PTFE base cloth layer is prepared by a weaving mode; (3) the catalyst-containing PTFE short fiber and a base material undergo composite acupuncture or spunlace on the surface of the PTFE base cloth layer so as to prepare a PTFE felt layer; (4) an active metal catalyst emulsion and a PTFE emulsion are mixed to prepare a catalyst mixed treating fluid, and the PTFE felt layer undergoes mass-impregnation treatment and then is sintered at 300-350 DEG C; and (5) the sintered PTFE felt layer and the catalyst-containing PTFE micro-porous membrane are simultaneously introduced into a hot laminator to undergo surface hot-press lamination processing. According to the invention, filtration accuracy and denitration and dioxin-removal efficiency can be enhanced remarkably.

Owner:辽宁新洪源环保材料有限公司

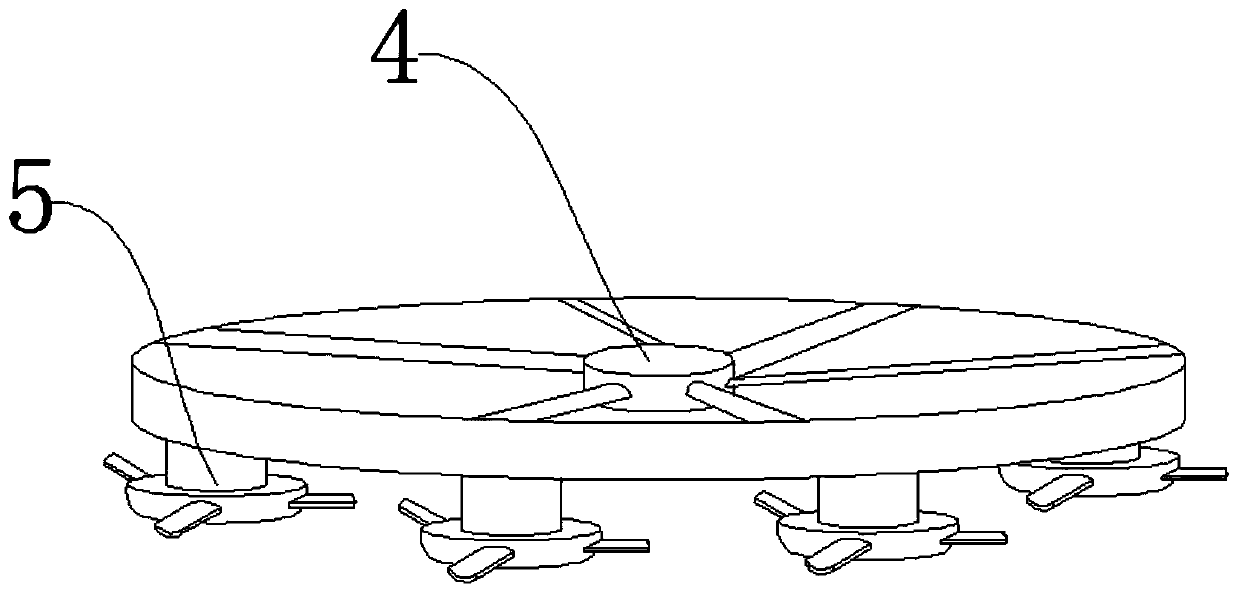

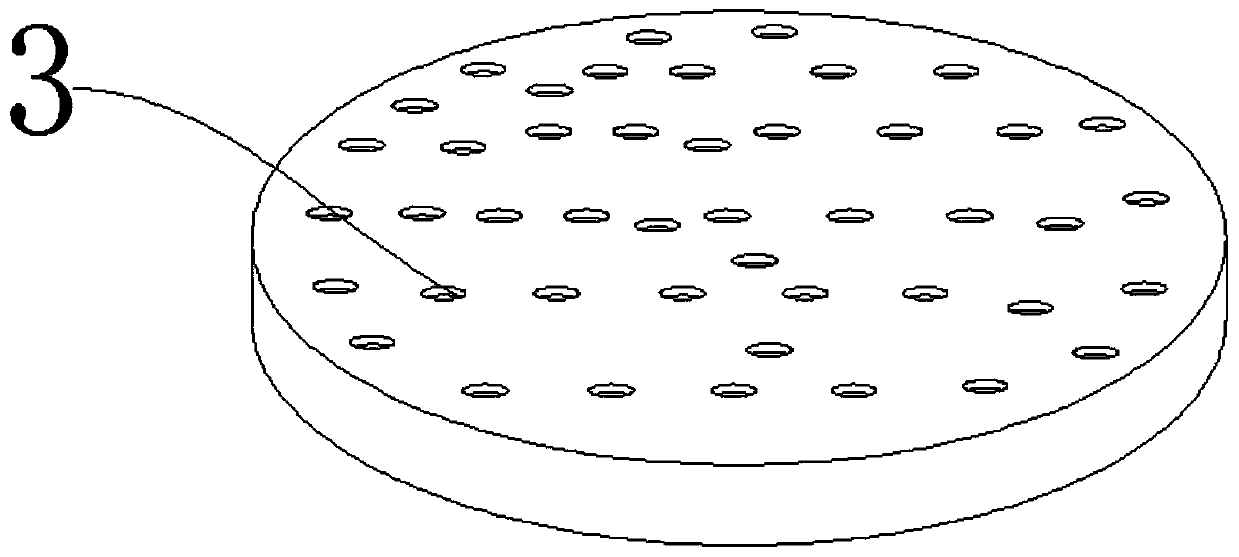

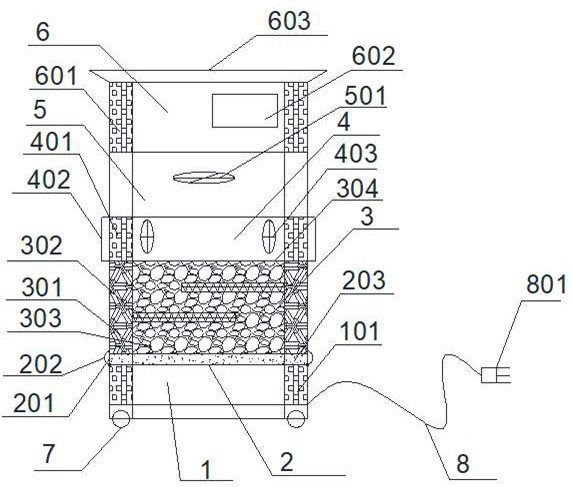

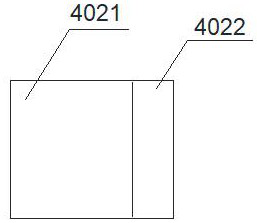

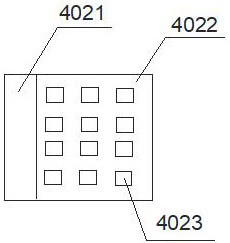

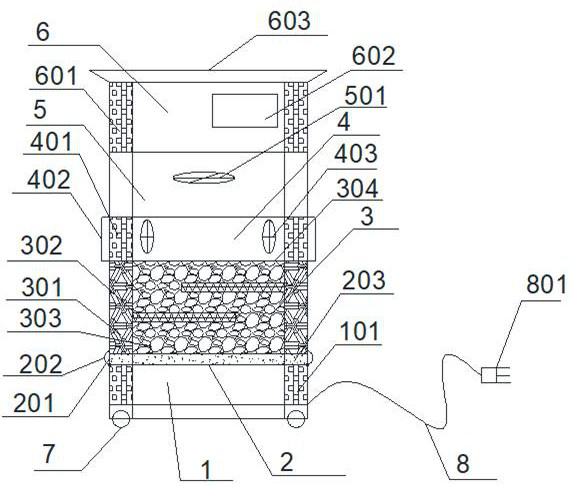

Waste gas treatment device of coating mechanical equipment

InactiveCN110559849AImprove catalytic decomposition efficiencyIncrease contact areaGas treatmentDispersed particle separationFixed frameFan blade

The invention discloses a waste gas treatment device of coating mechanical equipment, the waste gas treatment device comprises a filtering tower, a fixing frame and fan blades, the inner wall of the filtering tower is connected with the fixing frame through bolts, and the bottom end of the fixing frame is connected with the fan blades through bearings. The device has the beneficial effects that byarranging the filtering tower, the fixing frame and the fan blades, circulating waste gas can be disturbed and scattered, the contact area between the waste gas and the device is increased, the catalytic decomposition efficiency of the waste gas is improved, and the cost is saved.

Owner:夏枫

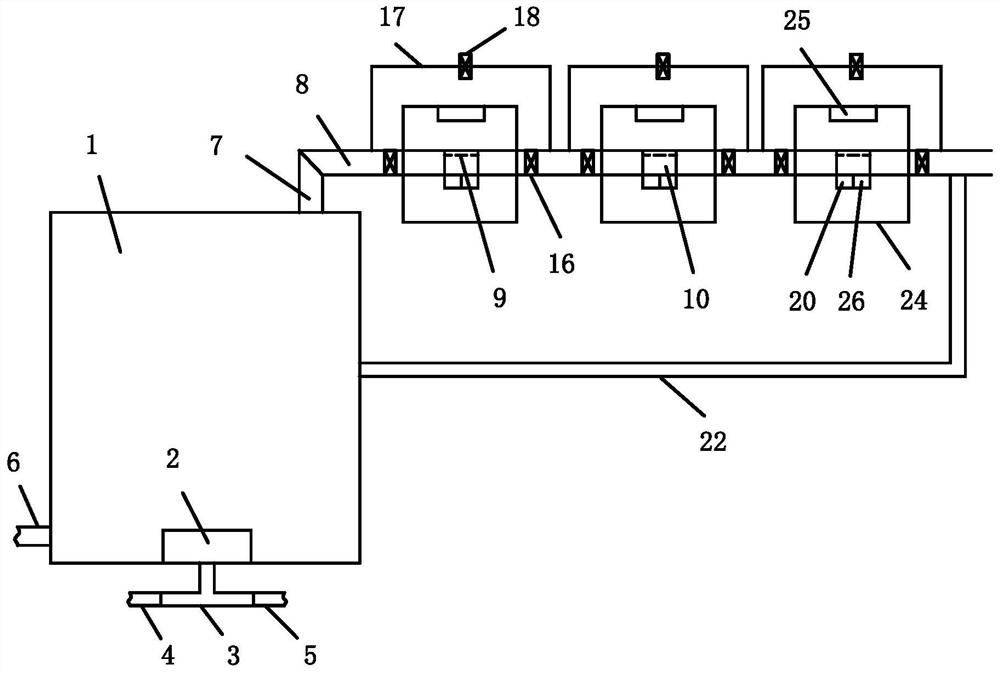

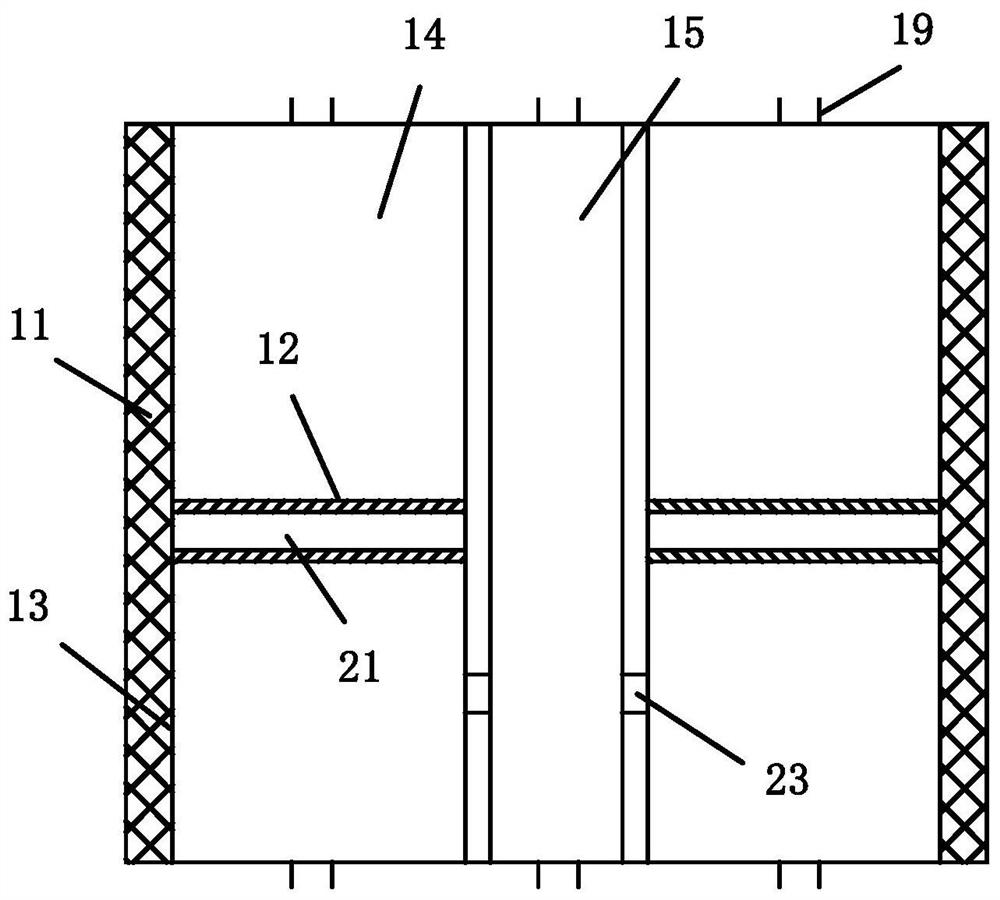

A method and equipment for treating sewage with nano-microwave ion induction technology

ActiveCN110028184BAchieve independent operationReduce pollutionMultistage water/sewage treatmentWater/sewage treatment apparatusPhysical chemistrySewage

The invention discloses a device for treating sewage with nano-microwave ion induction technology, which includes an aeration tank, an aeration plate is arranged at the bottom of the aeration tank, a water outlet is arranged at the top of the aeration tank, and a degradation treatment pipe is connected to the water outlet to degrade the waste water. There are several threaded holes fixed on the processing pipe, and a degradation treatment tank is threadedly connected to each threaded hole, a filter screen is arranged on the surface of the degradation treatment tank, a container is inserted into the degradation treatment tank, and several The first degradation chamber, the center of the container is fixed with the second degradation chamber, the two ends of each threaded hole are provided with a first stop valve, the two ends of each threaded hole are connected with a bypass pipe, and the bypass pipe is provided with There is a second cut-off valve, a microwave source and an ion source are installed at the bottom of the degradation treatment tank, and the end of the degradation treatment pipe is connected to the aeration tank through a return pipe. The invention can improve the deficiencies of the prior art and improve the operating rate of sewage treatment equipment.

Owner:广州绿邦环境技术有限公司

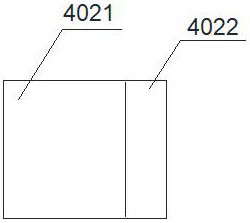

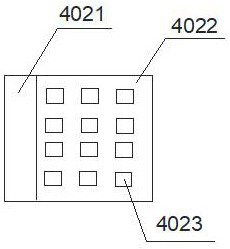

Fresh air handling unit with purification, sterilization and disinfection functions and purification, sterilization and disinfection process thereof

ActiveCN112963929AIncrease the heating areaExtended stayMechanical apparatusLighting and heating apparatusParticulatesBacterial virus

The invention discloses a fresh air handling unit with purification, sterilization and disinfection functions and a purification, sterilization and disinfection process thereof. The fresh air handling unit comprises an air inlet chamber, a gas purifying chamber, a gas heating and disinfecting chamber, a gas mixing chamber, a fan chamber and an air outlet chamber from bottom to top. Air inlets are formed in the four side walls of the air inlet chamber, and a filter screen mounting opening is formed in one side of the gas purifying chamber. A filter screen sealing element is arranged outside the filter screen mounting opening. A gas purification filter screen is mounted in the gas purifying chamber, heat insulation layers are arranged on the four side walls of the gas heating and disinfecting chamber, heating plates are mounted in the gas heating and disinfecting chamber, catalytic ceramic particles are filled between the heating plates, and a porous partition plate is mounted at the top of the gas heating and disinfecting chamber. An air supplementing opening is formed in the opposite side wall of the gas mixing chamber, an air supplementing adjusting plate is arranged outside the air supplementing opening, and a gas mixing fan is installed in the gas mixing chamber. The fresh air handling unit with the purification and disinfection functions can effectively remove particulate matter, VOC and other harmful gases in the air, kill bacteria, viruses and other microorganisms in the air, purify and disinfect the air and can also be used for heating in winter.

Owner:江苏舒源空调制造有限公司

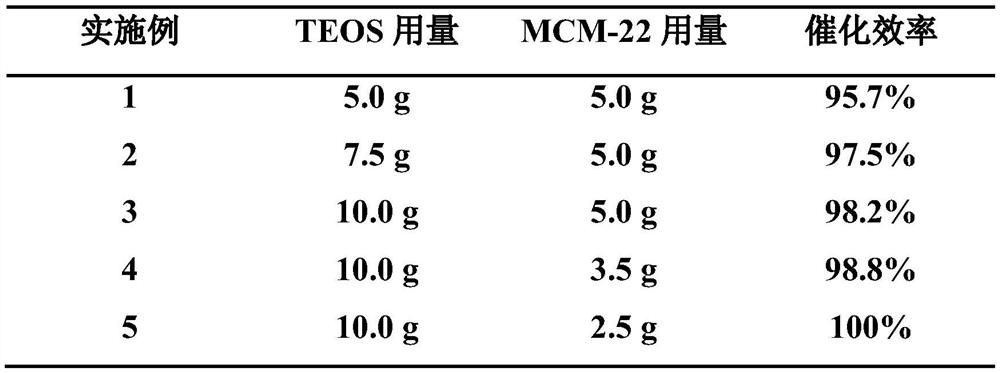

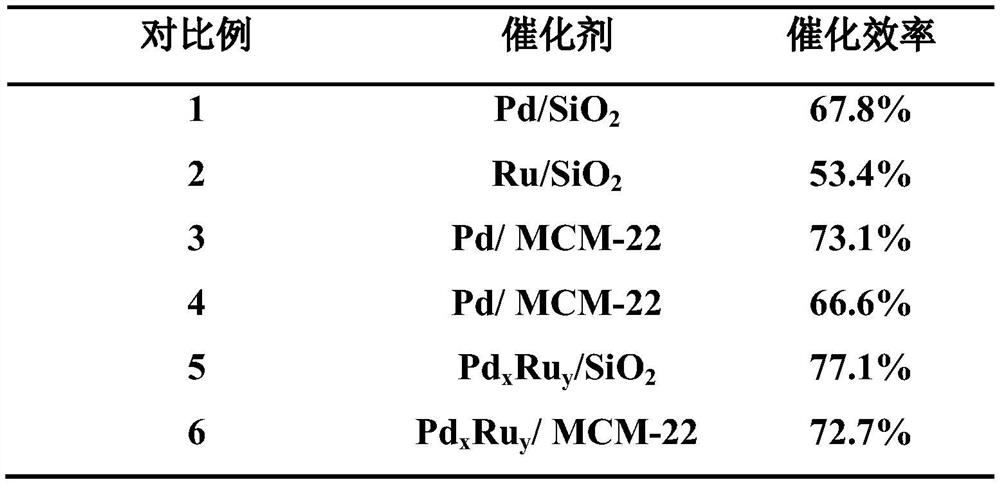

Composite metal catalyst for online hydrocarbon removal instrument and preparation method thereof

ActiveCN111822042ASolve the technical problem of low hydrocarbon removal efficiencyImprove catalytic decomposition efficiencyMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a composite metal catalyst for an online hydrocarbon removal instrument and a preparation method of the composite metal catalyst. The method is used for solving the technical problem of low catalytic efficiency of hydrocarbon substances of an online hydrocarbon removal instrument in the prior art. The method comprises the following steps of: S1, dissolving a template, Pd(NO3)2.6H2O and RuCl3.3H2O in a solvent I, and adding an alkaline solution to obtain a mixture; performing heating and separating to obtain a solid I; S2, adding the solid I, CTMAB, TEOS and a solvent IIinto a container, adding a precipitant for reaction, performing separation to obtain a solid II, and calcining the solid II to obtain PdxRuy / SiO2 nanoparticles; and S3, treating the PdxRuy / SiO2 nanoparticles, MCM-22 and water to obtain a molecular sieve water slurry, covering the surface of a carrier with the molecular sieve water slurry, performing drying, and conducting calcining to obtain the composite metal catalyst. The technical scheme of the invention is implemented, precious metals Pd and Ru are used as active components and are uniformly mixed with SiO2 and an MCM-22 molecular sieve,finally, the mixture is uniformly coated on the surface of a zeolite carrier to prepare the PdxRuy / SiO2 / MCM-22 / Zeolite composite metal catalyst, so that the catalytic decomposition efficiency of the online hydrocarbon removal instrument is effectively improved.

Owner:上海麦越环境技术有限公司

A kind of bactericidal and aldehyde-removing air filter membrane

ActiveCN107051232BImprove filtering effectPurification and decompositionSemi-permeable membranesBreathing filtersAir filtrationFiber

The invention discloses an air filtration membrane with functions of killing bacteria and removing formaldehyde. The air filtration membrane is of a three-layer nanofiber membrane composite structure, wherein the upper layer is an activated carbon nanofiber membrane, the middle layer is a pure TiO2 nanofiber membrane, and the lower layer is a nano-silver antibacterial fiber membrane; the pure TiO2 nanofiber membrane is prepared from a high polymer material / TiO2 precursor composite nanofiber membrane through heat treatment, and the high polymer material / TiO2 precursor composite nanofiber membrane is prepared with an electrospinning method; the activated carbon nanofiber membrane is an electrospun activated carbon nanoparticle / high polymer material composite nanofiber membrane; the nano-silver antibacterial fiber membrane is an electrospun nano-silver particle / high polymer material composite nanofiber membrane. The air filtration membrane not only can filter solid particulate pollutants very well, but also is good in breathability, and can remove and decompose formaldehyde in air and filter and kill harmful bacteria in air, thereby guaranteeing health of a respiratory system better.

Owner:保定源汉升新材料科技有限公司

A fresh air unit with purification, sterilization and disinfection functions and its purification, sterilization and disinfection process

ActiveCN112963929BIncrease the heating areaExtended stayMechanical apparatusLighting and heating apparatusParticulatesMicroorganism

The invention discloses a fresh air unit with purifying, sterilizing and disinfecting functions and its purifying, sterilizing and disinfecting process, which comprises an inlet chamber, a gas purification chamber, a gas heating and disinfection chamber, a gas mixing chamber, a fan chamber, and an air outlet chamber from bottom to top. There are air inlets on the four side walls of the gas chamber, a filter installation port on one side of the gas purification chamber, and a filter seal on the outside of the filter installation port, a gas purification filter installed in the gas purification chamber, and a gas heating and disinfection chamber on all four sides. The wall is provided with a heat insulation layer, and a heating plate is installed inside the gas heating and disinfection chamber, and catalytic ceramic particles are filled between the heating plates, a porous partition is installed on the top of the gas heating and disinfection chamber, and an air supply port is opened on the opposite side wall of the gas heating and disinfection chamber. , There is an air supply regulating plate outside the air supply port, and an air mixing fan is installed inside the air mixing chamber. The fresh air unit with purification and disinfection functions of the present invention can effectively remove harmful gases such as particulate matter and VOC in the air, kill microorganisms such as bacteria and viruses in the air, purify and disinfect the air, and can also be used for heating in winter.

Owner:江苏舒源空调制造有限公司

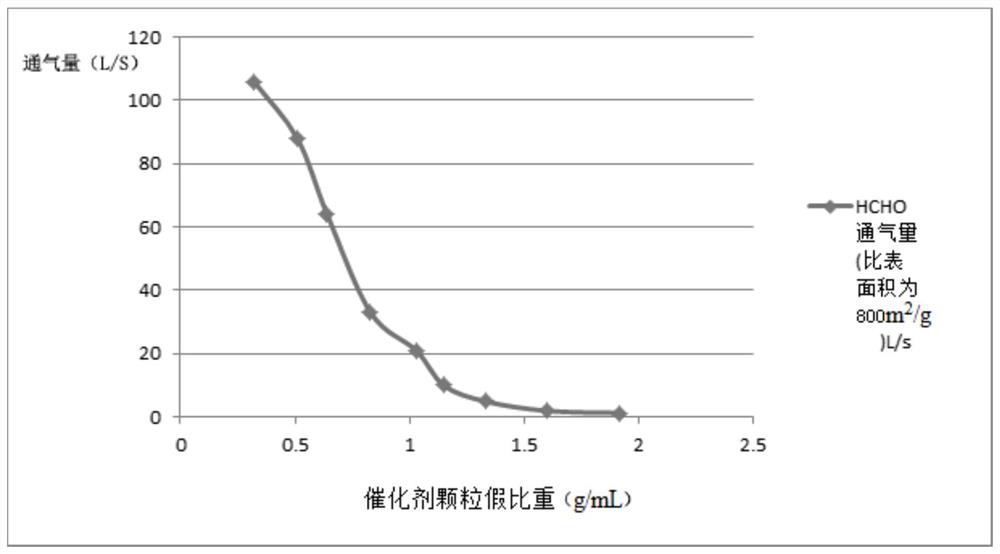

A composite material for air purification

ActiveCN110624398BHigh VOC enrichment capacityGood aerodynamic passabilityGas treatmentDispersed particle filtrationPtru catalystFiltration

The invention discloses an air purification composite material, which includes a VOC catalytic digestion layer, wherein the VOC catalytic digestion layer includes an active component, an activator and a catalyst carrier. The invention provides a low-resistance and high-efficiency air-purifying composite material, which can achieve extremely high interception efficiency by superimposing multi-layer filter materials; adopts multi-stage filtration to classify solid pollutants, and has a better filtering effect , The service life and effect of the material are longer.

Owner:ZHEJIANG CHENWEI ENVIRONMENTAL TECH CO LTD

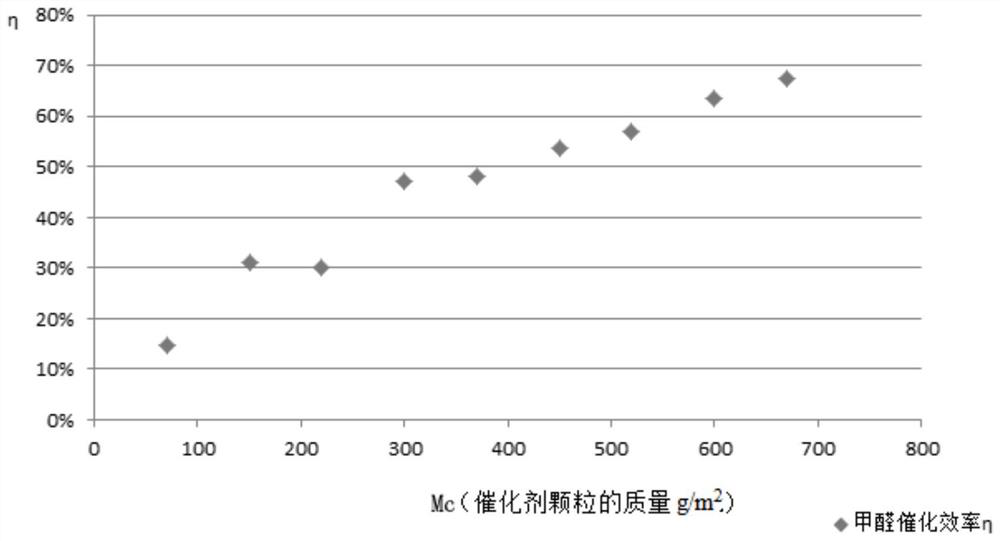

A recovery and treatment process of sodium chloride electrolysis industrial tail gas

ActiveCN105833703BRealize truly harmless recyclingAchieve recyclingDispersed particle separationAlkali metal chloridesElectrolysisFiltration

The invention relates to a process for recovery of sodium chloride electrolysis industrial exhaust. There is no process for recycling of sodium chloride solution at present. The process for recovery of sodium chloride electrolysis industrial exhaust comprises the steps that sodium hydroxide solution is made into foam by means of a dynamic wave absorption device and makes full contact with sodium chloride electrolysis industrial exhaust to form absorption liquid containing sodium hypochlorite, the absorption liquid enters an absorption tower to absorb sodium chloride electrolysis industrial exhaust in a circulating mode till a set value is obtained when the concentration of sodium hypochlorite in the absorption liquid is smaller than the set value, the absorption liquid is then delivered to a decomposition tower, a catalyst is formed by mixing of copper oxide and manganese dioxide and decomposes sodium hypochlorite in the absorption liquid into oxygen and sodium chloride, and after the absorption liquid enters a regulating tank, Na2SO3 used as a reducing agent, sodium hydroxide used as a pH regulator and BaCl2 used as a precipitator are added in sequence for filtration, so that sodium chloride solution meeting the requirement of the sodium chloride electrolysis process is obtained. Recycling of sodium chloride solution can be achieved through the process.

Owner:浙江钛合工程技术有限公司

A filter material with desulfurization effect and preparation method thereof

ActiveCN105013250BApplicable to a wide range of working conditionsReduce consumption costsDispersed particle filtrationSynthetic resin layered productsEmulsionMetal catalyst

The invention provides a preparation method of a filtering material possessing desulphurization efficacy, which comprises the following steps: 1)active metal catalyst powder and PTFE resin powder are mixed and respectively prepared to catalyst-containing PTFE fiber and catalyst-containing PTFE micropore film; 2) catalyst-containing PTFE fiber and high-strength PTFE fiber employs an alternative arrangement mode with 1-10: 1-10 to prepare warp beam, a PTFE base cloth layer is prepared by employing a machine knitting mode; 3)the base material and catalyst-containing PTFE fiber are mixed, and then placed in a needle loom with the PTFE base cloth layer to prepare PTFE composite needled felt; 4)an active metal catalyst emulsion and a PTFE emulsion are mixed to prepare a catalyst mixing treatment fluid, the PTFE composite needled felt is performed with integral dipping treatment and sintered at temperature of 280-350 DEG C; and 5)the sintered PTFE composite needled felt and the catalyst-containing PTFE micropore film are simultaneously introduced into a heat film covering machine, and the surface is performed with hot pressing and laminating. According to the invention, filtration accuracy as well as desulphurization efficiency can be greatly increased.

Owner:辽宁新洪源环保材料有限公司

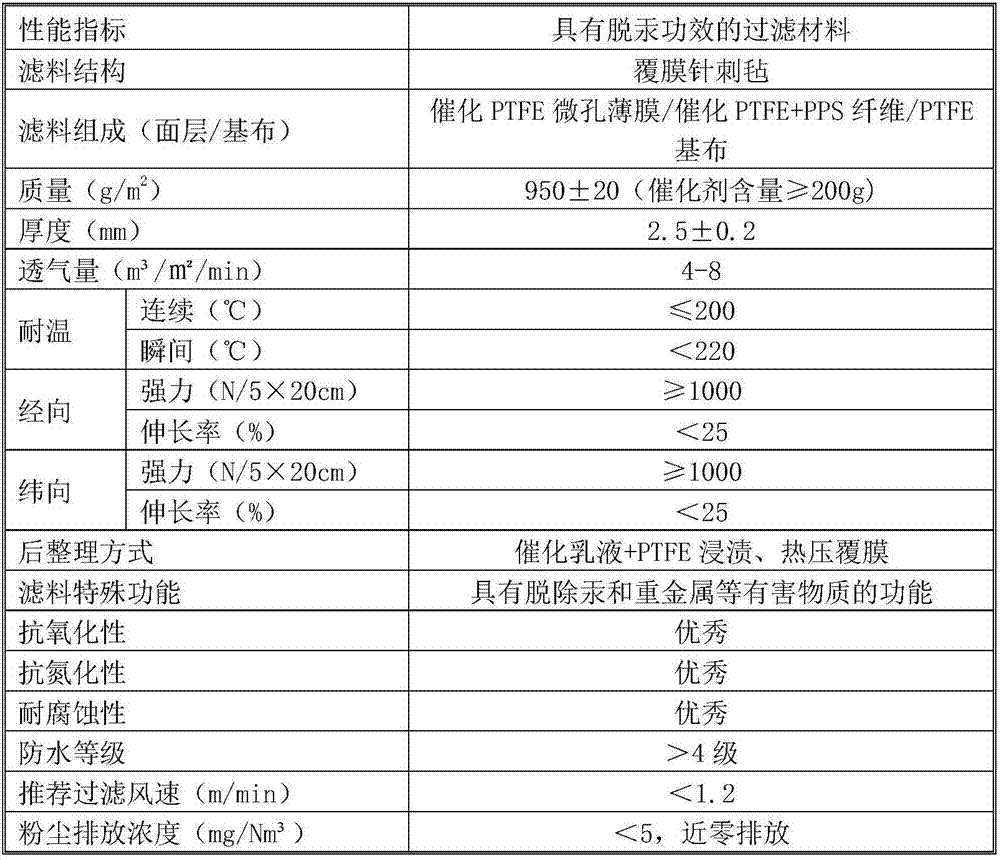

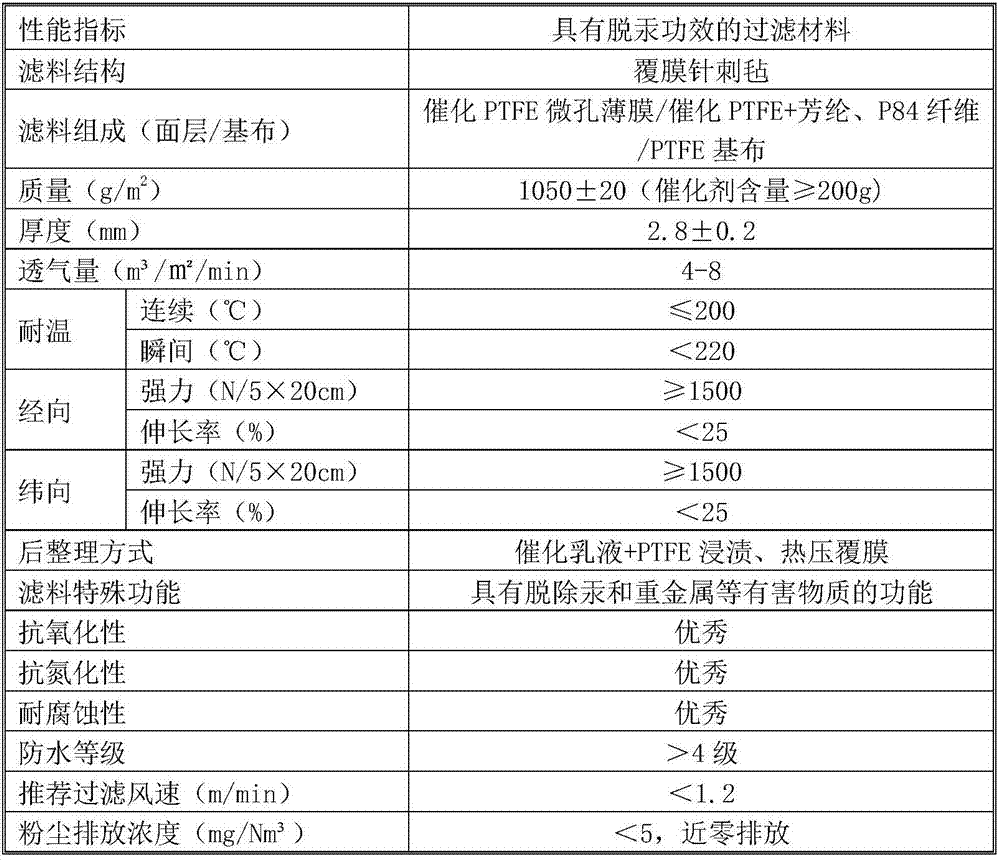

A filter material with mercury removal effect and preparation method thereof

ActiveCN105013246BApplicable to a wide range of working conditionsReduce consumption costsSynthetic resin layered productsDispersed particle separationEmulsionPolymer science

The invention provides a method for preparing a filter material with mercury removal effect, comprising the following steps: (1) After mixing active metal catalyst powder and PTFE resin powder, respectively making PTFE fibers containing catalyst and PTFE microparticles containing catalyst Porous film; (2) the PTFE fiber that contains catalyst and the high-strength PTFE fiber adopt the mode that 1-10:1-10 is alternately arranged to make warp beam, adopt the mode of weaving to make PTFE base cloth layer; (3) base Material is mixed with PTFE short fibers containing catalyst and then put into needle punching machine together with PTFE base cloth layer to make PTFE composite needle felt; (4) Mix active metal catalyst emulsion and PTFE emulsion to make catalyst mixed treatment liquid. The PTFE composite needle felt is sintered at 280-350°C after the overall impregnation treatment; (5) The sintered PTFE composite needle felt and the PTFE microporous film containing the catalyst are simultaneously introduced into the hot laminating machine, and the surface is hot pressed Laminating processing. The invention can remarkably improve the filtering accuracy and the mercury and heavy metal removal efficiency.

Owner:辽宁新洪源环保材料有限公司

Supported metal oxide catalyst for assisted microwave denitrification, preparation method and use method thereof

ActiveCN105170150BHigh activityReduce loadDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMicrowaveActive component

The invention discloses a supported metal oxide catalyst for assisting microwave denitrification, a preparation method and a use method thereof. The catalyst is a supported catalyst with carbon as a carrier and metal oxide as an active component; the catalyst The carrier is carbon, not only the source is convenient, but also the specific surface area is large, which can play a good role in dispersing the active components of the catalyst, and there will be no agglomeration between the components; the metal oxides used have high activity and the required loading The amount is small; carbon-supported metal oxides have good microwave absorption capacity, and can well exert the synergistic effect of microwaves and catalysts. The catalytic decomposition efficiency of nitrogen oxides is high, and the decomposition rate of NO can be as high as 98%. The catalytic decomposition temperature of the method is low, and the loss of the carbon carrier is low.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

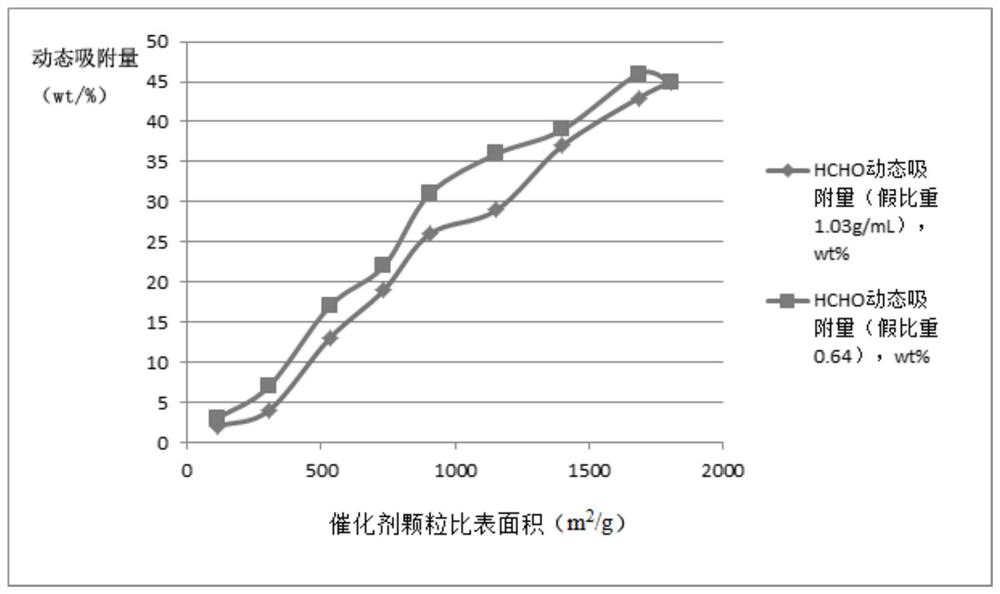

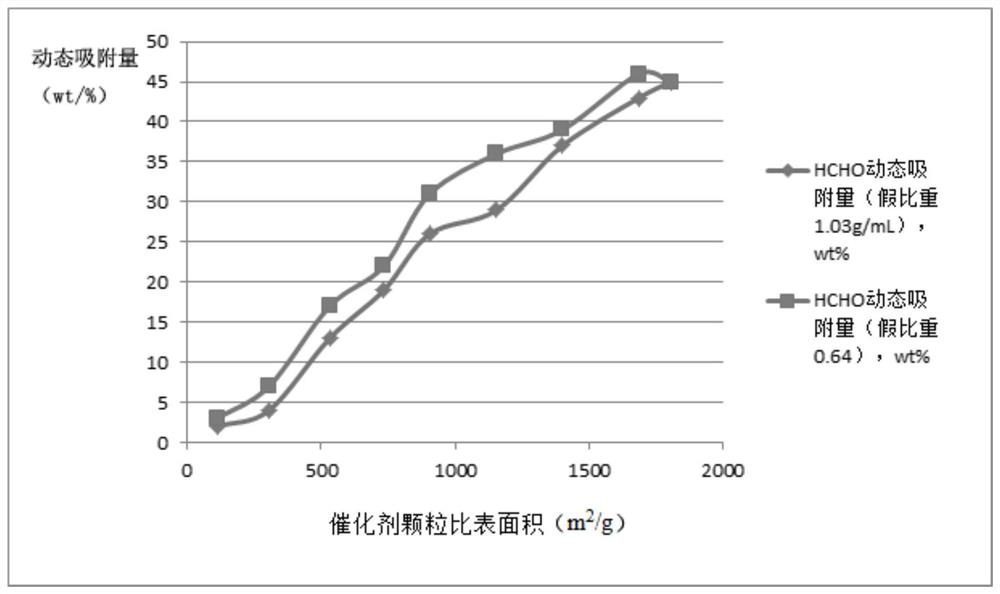

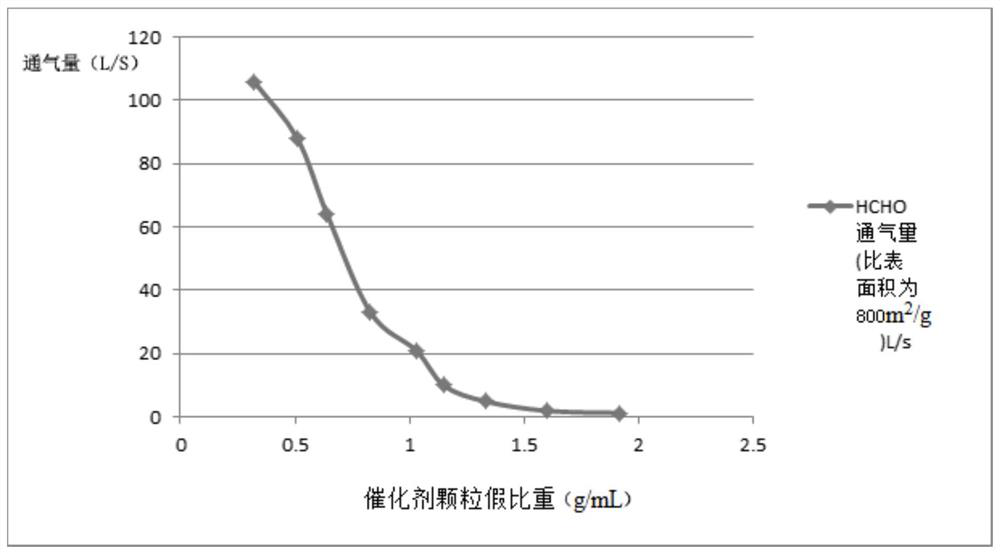

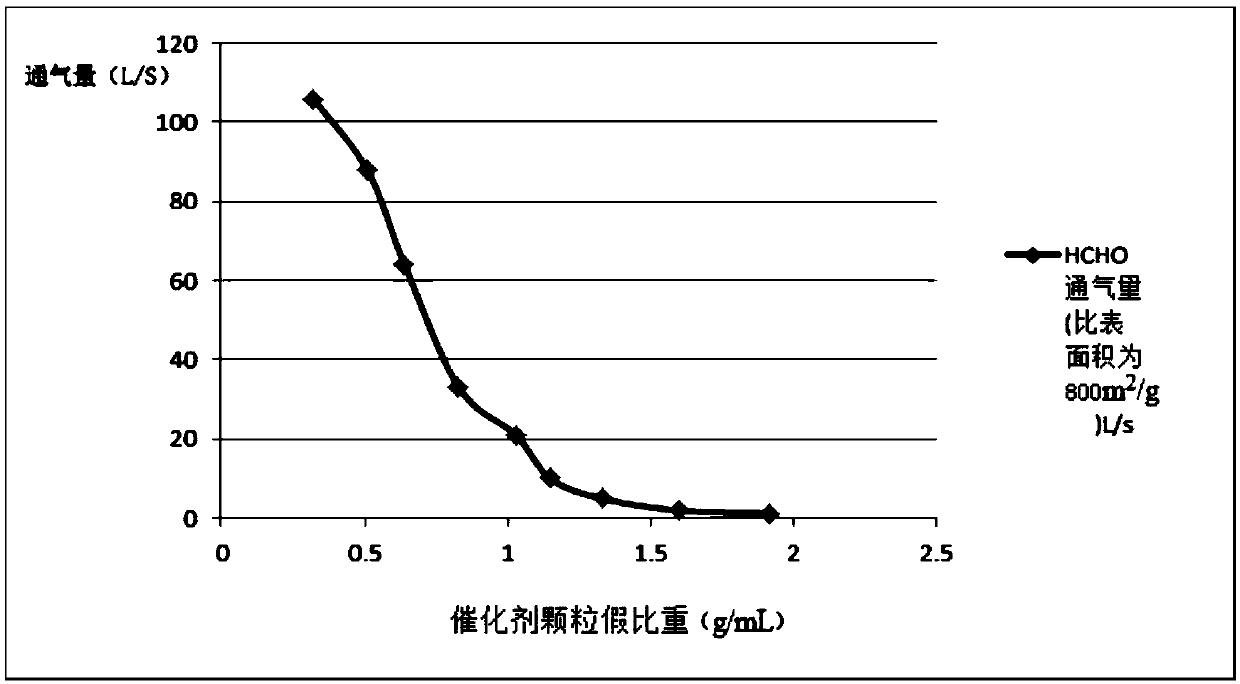

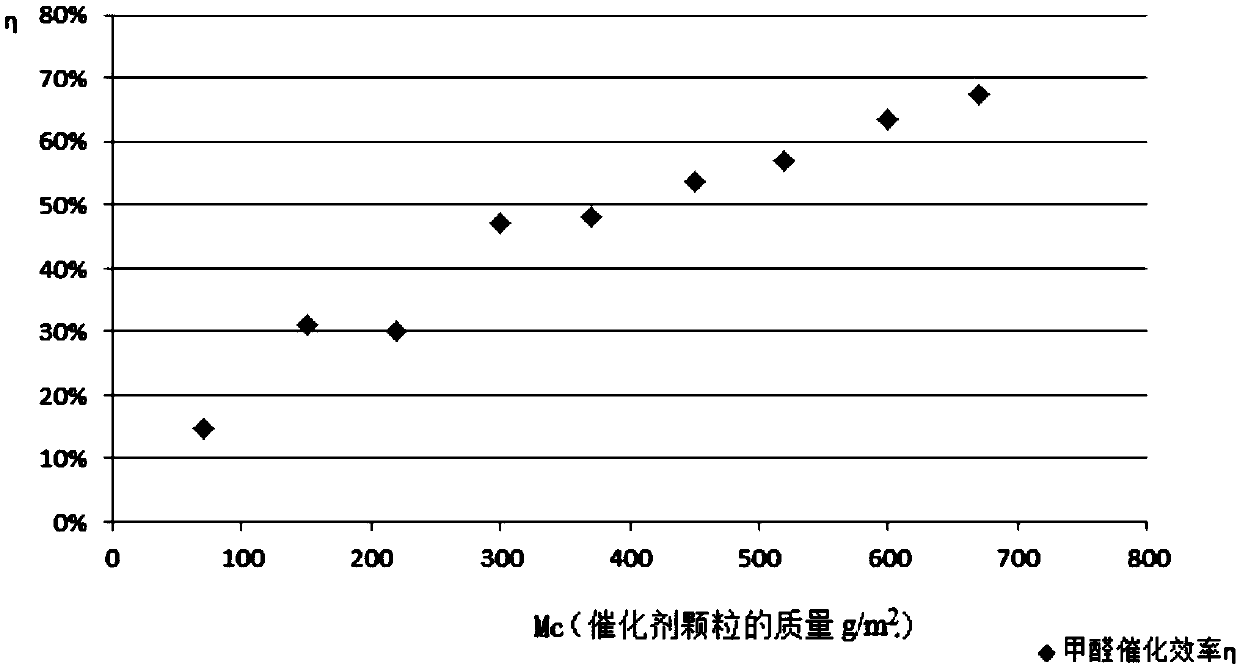

Preparation method of supported catalyst

ActiveCN110624544BFine adjustment of evaporation speedControl macroscopicGas treatmentDispersed particle separationPtru catalystCatalyst support

The invention discloses a method for preparing a supported catalyst, which comprises heating the mixture of active components, catalyst supports and pore-forming agents, wherein the heating temperature is above the boiling point of the pore-forming agents. The preparation method can not only change the macroscopic morphology of the supported catalyst, but also control the macroscopic morphology of its particles and affect the internal microscopic morphology.

Owner:ZHEJIANG CHENWEI ENVIRONMENTAL TECH CO LTD

A pulsed biomimetic power device based on monocomponent fuel and its control method

InactiveCN105977511BLower activation energyImprove power densityReactant parameters controlExoskeleton robotControl signal

The invention provides an impulse-type bionic power device based on a single-component fuel. The device mainly consists of a fuel supply system and an impulse-type reaction system, wherein the fuel supply system is used for realizing storage and flow regulation and control of single-component fuels; the single-component fuels sequentially pass through an inlet high-frequency switch valve and a catalyst bed of the impulse-type reaction system and are decomposed from a liquid state into a gas state under the action of a catalyst, so that the internal pressure of the catalyst bed increases rapidly; the whole process can be divided into three stages, namely an input stage, a reaction stage and a spraying stage; during the input stage, the inlet high-frequency switch valve is opened, and an outlet high-frequency switch valve is closed; during the reaction stage, the inlet high-frequency switch valve and the outlet high-frequency switch valve are closed; during the spraying stage, the outlet high-frequency switch valve is opened, and the inlet high-frequency switch valve is closed. The device is capable of obtaining the flow of a flow pump and parameter values such as PWM control signal duty ratio of the inlet high-frequency switch valve and the outlet high-frequency switch valve by use of formulae of thermodynamics and hydromechanics according to the output force requirement, and generating a continuous impulse spraying effect. The impulse-type bionic power device has the advantages of high power density, environmental friendliness, simple structure, high efficiency and the like, and is applicable to power systems of devices such as exoskeleton robots and jet packs.

Owner:NAT UNIV OF DEFENSE TECH

A kind of air purification composite catalyst and preparation method thereof

ActiveCN106334565BImprove surface activityRealize catalytic decomposition reactionMolecular sieve catalystsHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

An air purification composite catalyst and a preparation method thereof. The air purification composite catalyst comprises a manganese oxide, a composite copper oxide and a cerium oxide. The preparation method comprises the following steps: dissolving an oxidizing agent, an Mn(II) salt, a Cu(II) salt and a Ce(III) salt into a solvent, mixing and reacting the same, transferring the mixture to a high-pressure reaction vessel, performing a high-temperature high-pressure reaction, filtering, cleaning and drying the same to obtain a composite catalyst precursor; mixing the composite catalyst precursor with an auxiliary material and clay to obtain composite granulated powders; and granulating the composite granulation powder to obtain an air purification composite catalyst. The prepared composite catalyst is high in surface activity and high in catalytic performance.

Owner:UCHEER PURIFICATION & POLLUTION CONTROL TECH ZHEJIANG CO LTD

Supported catalyst preparation method

ActiveCN110624544AFine adjustment of evaporation speedControl macroscopicGas treatmentDispersed particle separationBoiling pointActive component

The invention discloses a supported catalyst preparation method, which comprises: heating a mixture of an active component, a catalyst carrier and a pore-forming agent, wherein the heating temperatureis higher than the boiling point of the pore-forming agent. According to the invention, with the preparation method, the macroscopic form of the supported catalyst can be changed, the macroscopic form of the particles of the supported catalyst can be controlled, and the internal microcosmic form can be affected.

Owner:ZHEJIANG CHENWEI ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com