Filter material with denitration and dioxin-removal effects and preparation method thereof

A filter material and efficacy technology, applied in the field of filter materials with denitration and dioxin effects and their preparation, to achieve the effects of wide range of applicable working conditions, improved catalytic decomposition efficiency, reduced energy consumption and operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

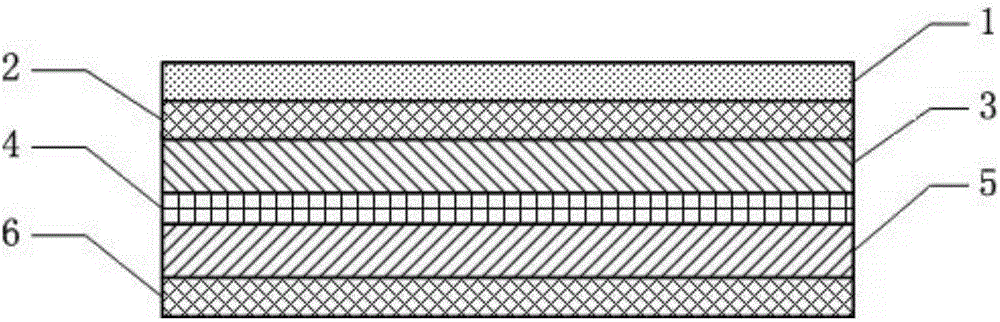

Image

Examples

preparation example Construction

[0030] A preparation method of a filter material with denitrification and dioxin effects, comprising the following steps: (1) after mixing active metal catalyst powder and PTFE resin powder, respectively making PTFE fibers containing catalyst and PTFE micropores containing catalyst film; (2) the PTFE fibers containing the catalyst and the high-strength PTFE fibers are alternately arranged in 1-10:1-10 to make a warp beam, and the PTFE base cloth layer is made by weaving in a weaving manner; (3) in PTFE The surface of the base cloth layer is composited with needle-punched or hydroentangled PTFE short fibers containing a catalyst and a base material to make a PTFE felt layer; (4) mixing the active metal catalyst emulsion with the PTFE emulsion to make a catalyst mixed treatment liquid, which is used for the PTFE felt The material layer is impregnated as a whole, and then sintered at 300-350°C; (5) The sintered PTFE felt layer and the PTFE microporous film containing the catalyst ...

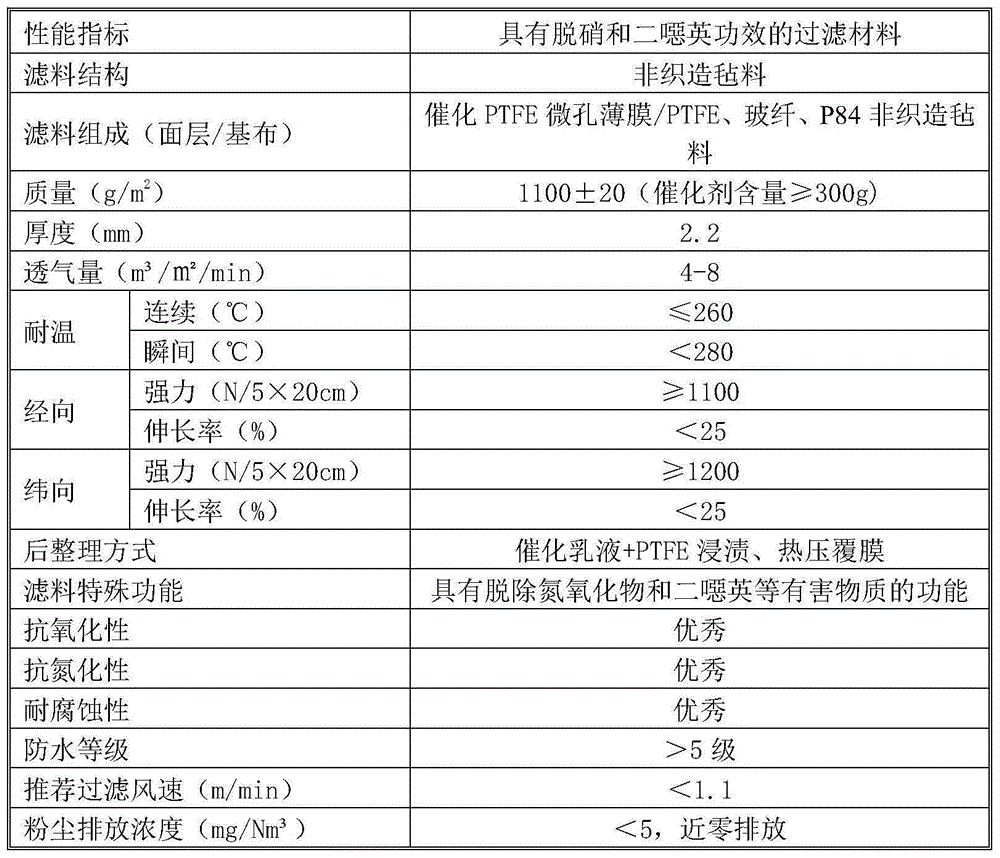

Embodiment 1

[0033] The active catalyst WO 3 、MoO 3 / TiO 2 The micropowder and PTFE resin are uniformly mixed together at a mass ratio of 3:97 to make PTFE fibers containing catalysts and PTFE microporous films containing catalysts respectively; among them, the type and quality of additives can be arbitrarily selected according to needs. The PTFE fiber containing the catalyst is mainly used to make woven filter cloth, and the PTFE microporous film containing the catalyst is finally coated on the surface of the filter material. By implanting an active catalyst in the filter material, it can achieve the effect of removing harmful substances such as nitrogen oxides and dioxins in the flue gas while filtering the flue dust. Specific steps are as follows:

[0034]One is the warping process of PTFE fibers containing catalysts and high-strength PTFE fibers before weaving. The warp beam is made by alternately arranging the mass ratio of 2:1, and the PTFE base cloth layer is made by weaving. 4;...

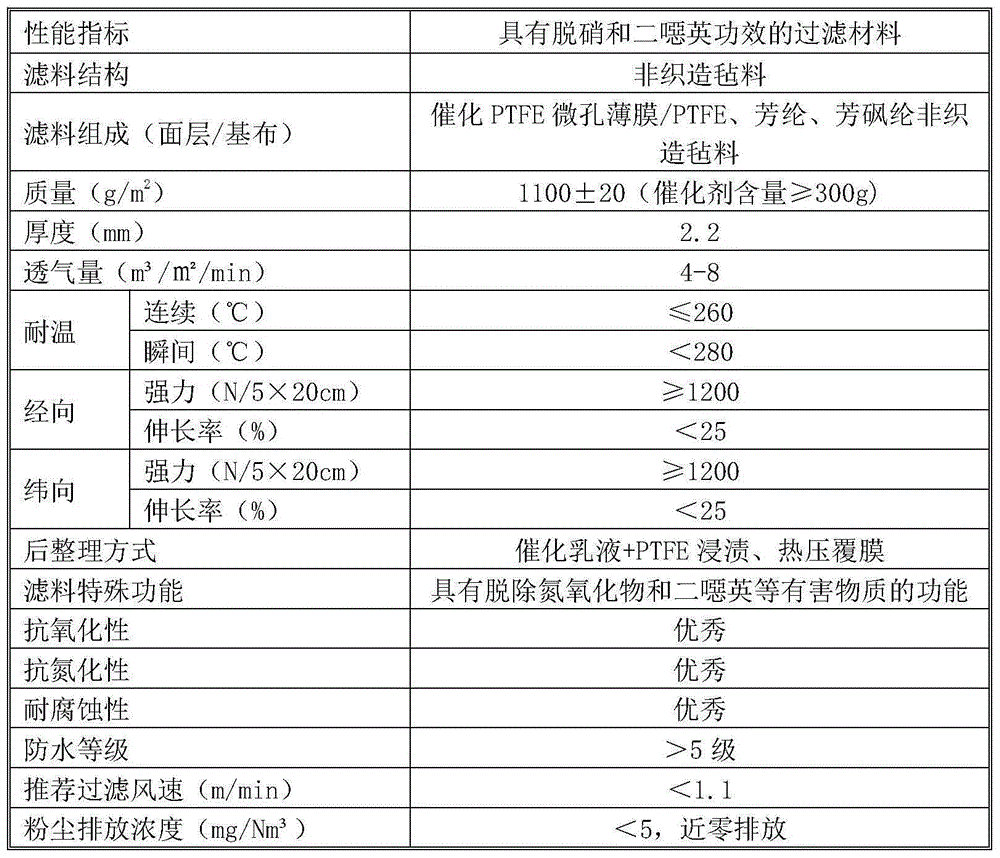

Embodiment 2

[0043] The active catalyst V 2 o 5 / TiO 2 The micropowder and PTFE resin are uniformly mixed together at a mass ratio of 10:90 to make PTFE fibers containing catalysts and PTFE microporous films containing catalysts respectively; among them, the type and quality of additives can be arbitrarily selected according to needs. The PTFE fiber containing the catalyst is mainly used to make woven filter cloth, and the PTFE microporous film containing the catalyst is finally coated on the surface of the filter material. By implanting an active catalyst in the filter material, it can achieve the effect of removing harmful substances such as nitrogen oxides and dioxins in the flue gas while filtering the flue dust. Specific steps are as follows:

[0044] One is the warping process of PTFE fibers containing catalysts and high-strength PTFE fibers before weaving. The warp beams are made by alternately arranging the mass ratio of 2:2, and the PTFE base cloth layer is made by weaving. 4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com