Filtering material possessing desulphurization efficacy and preparation method thereof

A filter material and efficiency technology, which is applied in the field of environmental protection, dust removal and flue gas purification, to achieve the effects of a wide range of applicable working conditions, reduced operation and maintenance costs, and improved catalytic decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

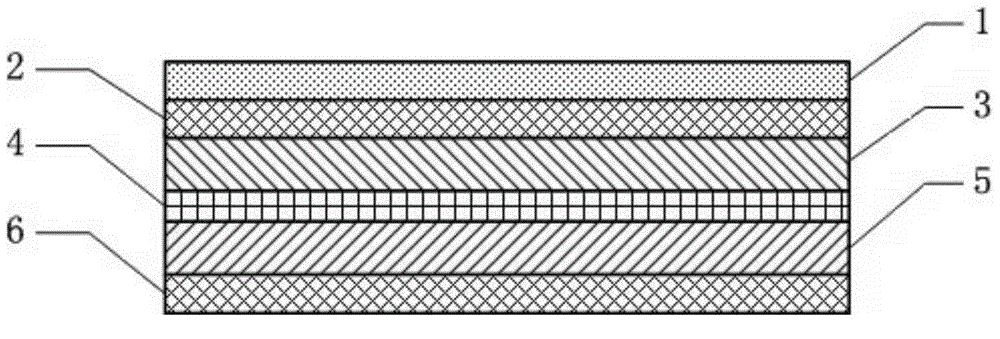

[0030] A preparation method of a filter material with desulfurization effect, comprising the following steps: (1) after mixing active metal catalyst powder and PTFE resin powder, respectively making PTFE fiber containing catalyst and PTFE microporous film containing catalyst; (2 ) The PTFE fiber containing the catalyst and the high-strength PTFE fiber are made into a warp beam in a 1-10:1-10 alternate arrangement, and the PTFE base cloth layer is made into a PTFE base cloth layer by weaving; (3) the base material and the catalyst-containing Put the PTFE staple fiber into the needle punching machine together with the PTFE base cloth layer after mixing, and form a catalytic PTFE fiber strength layer on both sides of the PTFE base cloth layer to make a PTFE composite needle felt; (4) mix the active metal catalyst emulsion with PTFE emulsion is mixed to make a catalyst mixed treatment solution, and the PTFE composite needle felt is impregnated as a whole, and then sintered at 280-3...

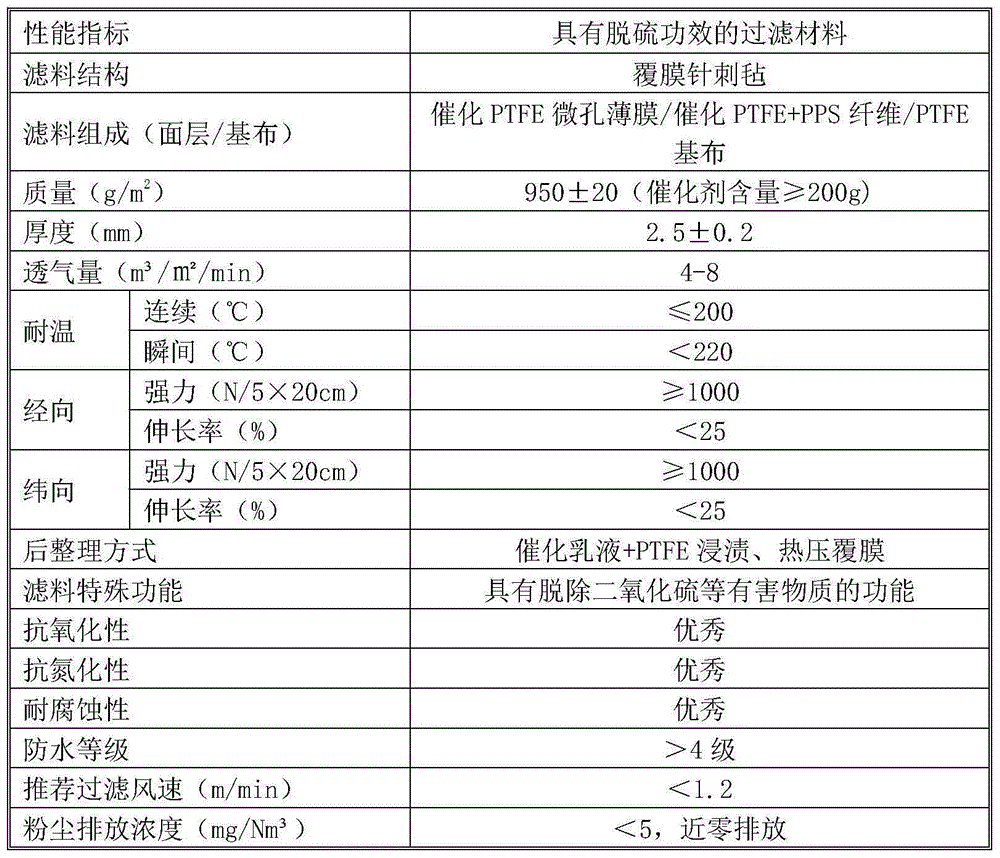

Embodiment 1

[0033] The active catalyst V 2 o 5 / TiO 2 The micropowder and PTFE resin are uniformly mixed together at a ratio of 5:95 to make PTFE fibers containing catalysts and PTFE microporous films containing catalysts respectively; among them, the type and quality of additives can be arbitrarily selected according to needs. The PTFE fiber containing the catalyst is mainly used to make woven filter cloth, and the PTFE microporous film containing the catalyst is finally coated on the surface of the filter material. By implanting an active catalyst in the filter material, it can achieve the effect of removing sulfur dioxide and other harmful substances in the flue gas while filtering the flue dust. Specific steps are as follows:

[0034] One is the warping process of PTFE fibers containing catalysts and high-strength PTFE fibers before weaving, using a 1:1 alternate arrangement to make warp beams, and weaving them into PTFE base fabrics by weaving to obtain PTFE base fabric layers 4;...

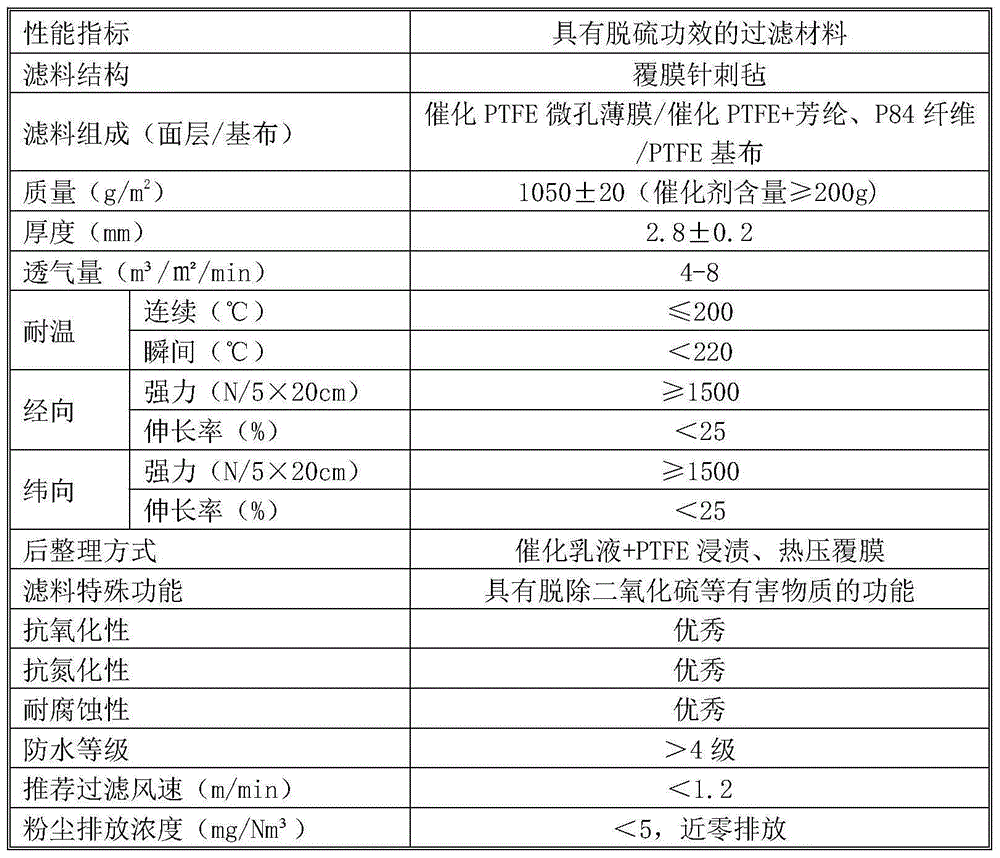

Embodiment 2

[0043] The active catalyst V 2 o 5 -WO 3 / TiO 2 The micropowder and PTFE resin are uniformly mixed together at a ratio of 8:92 to make PTFE fibers containing catalysts and PTFE microporous films containing catalysts respectively; among them, the type and quality of additives can be arbitrarily selected according to needs. The PTFE fiber containing the catalyst is mainly used to make woven filter cloth, and the PTFE microporous film containing the catalyst is finally coated on the surface of the filter material. By implanting an active catalyst in the filter material, it can achieve the effect of removing sulfur dioxide and other harmful substances in the flue gas while filtering the flue dust. Specific steps are as follows:

[0044] One is the warping process of PTFE fibers containing catalysts and high-strength PTFE fibers before weaving, using a 1:1 alternate arrangement to make warp beams, and weaving them into PTFE base fabrics by weaving to obtain PTFE base fabric lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com