Wharf platform pipeline cold insulation system and method of offshore LNG receiving station

A technology of receiving station and cooling system, applied in pipeline system, container discharge method, container filling method, etc., can solve the problems of large temperature difference between the upper and lower surfaces of low-temperature pipelines, and cannot be individually modified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

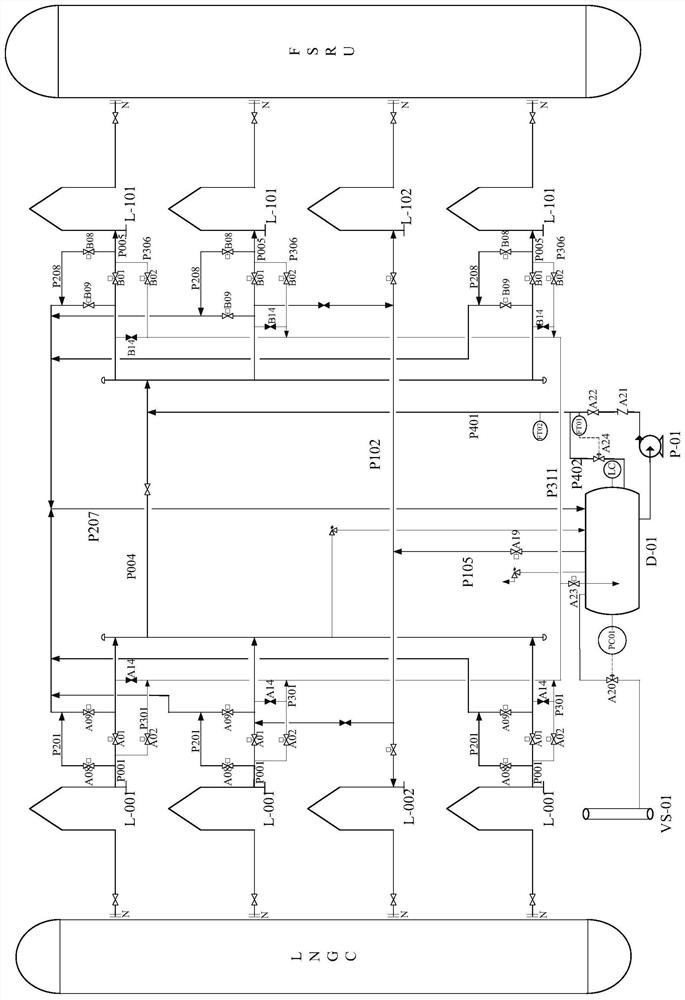

[0034] Such as figure 2 As shown, firstly, the cooling system of the dock platform pipeline of a kind of offshore LNG receiving station provided by the present invention is introduced, which has the ship unloading arm L-001, the Air arm L-002, of which:

[0035]The ship unloading arm L-001 is connected to the LNGC through the manifold port N, and each ship unloading arm L-001 is connected to the ship unloading main pipe P004 through the ship unloading branch pipe P001, and the ship unloading main pipe P004 is connected to the ship loading arm through each ship loading branch pipe P005 L-101, the loading arm L-101 is connected to the FSRU through the manifold port N, so as to transport the LNG in the LNGC to the storage tank of the FSRU to realize the loading action;

[0036] The loading air return arm L-102 is connected to the FSRU through the manifold port N, and is connected to the unloading air return arm L-002 through the BOG return air main pipe P102, and the ship unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com