Composite air purification catalyst and preparation method thereof

A composite catalyst and air purification technology, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of difficult to meet the needs of air purification, low performance activity, low specific surface area, etc., and achieve accelerated catalysis Decomposition efficiency, improved catalytic performance, high surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

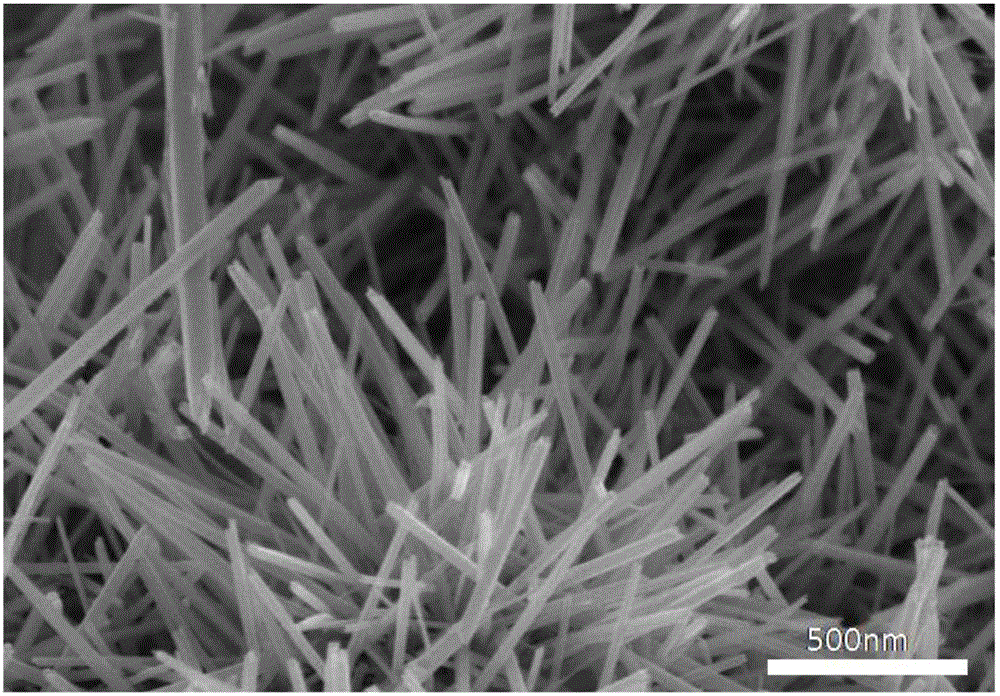

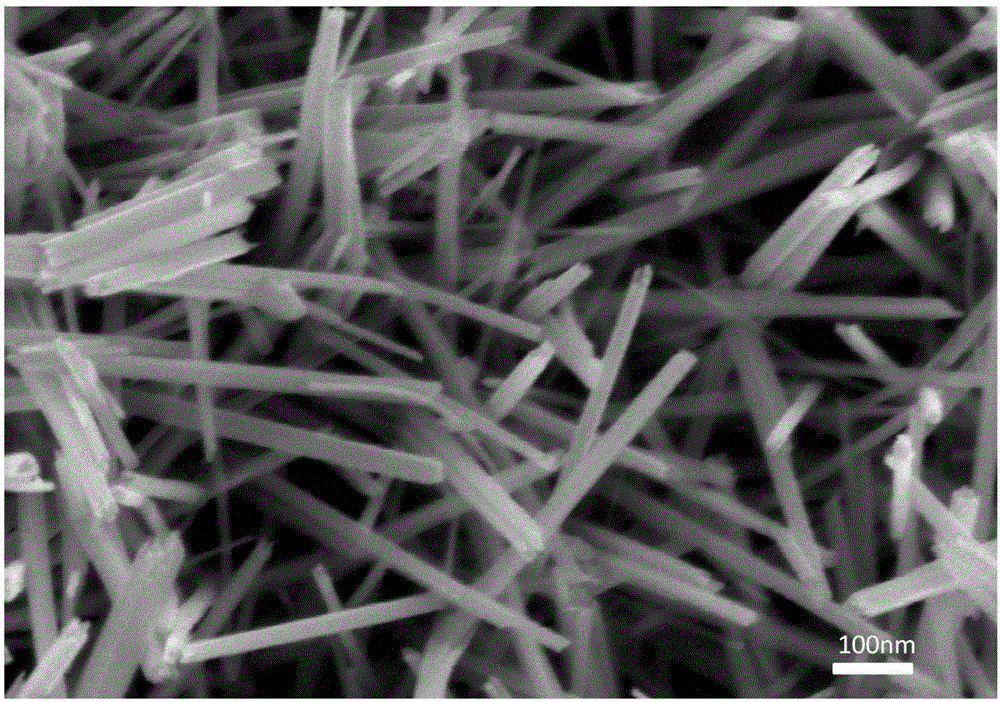

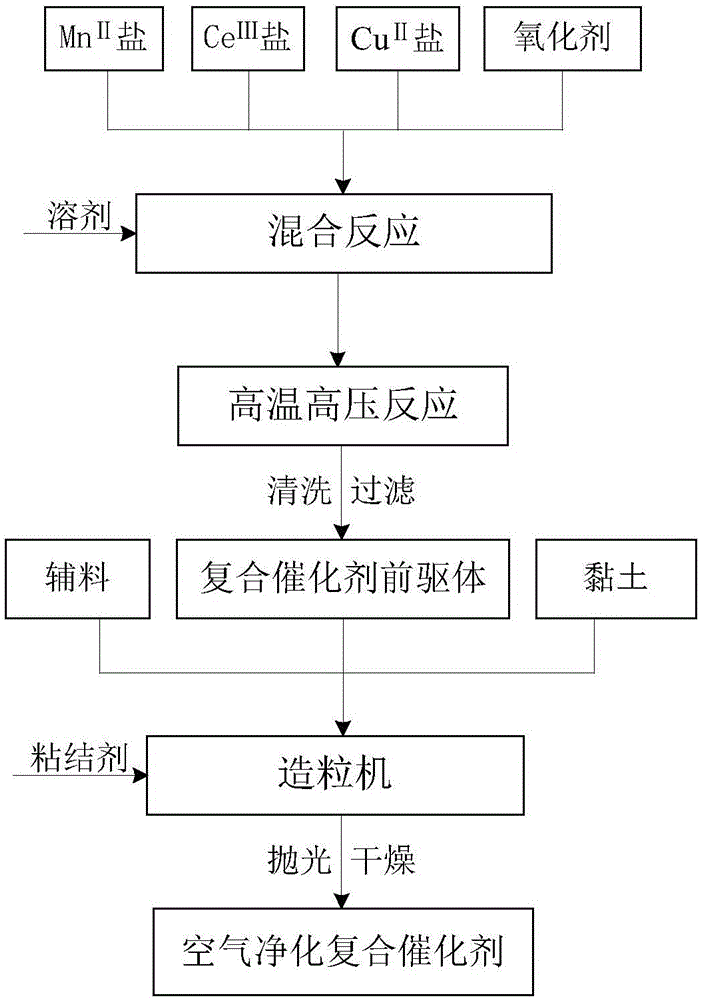

[0059] Add 39.5g of potassium permanganate, 19.8g of manganese chloride tetrahydrate, 12.5g of copper sulfate pentahydrate and 13.6g of cerium nitrate hexahydrate in 1708g of pure water in turn, stir until fully dispersed and dissolved, and the speed of the mixer is 10r / min , reacted at 0°C for 300min. The above mixed solution was transferred to a high-pressure reactor, set to react at 150°C for 16 hours, then taken out, washed and filtered, and then dried at 60°C for 30 hours to obtain the air purification composite catalyst precursor.

[0060] Mix the above-mentioned composite catalyst precursor, silicon dioxide and clay uniformly according to the mass ratio of 1:2:1 to obtain composite granulated powder for use. Select 0.1mm alumina particles and add them to the disc granulator at a rotation speed of 60r / min for granulation. Water is used as a binder during the granulation process, and the mass ratio of composite granulation powder to water is The ratio is 1:0.2, and the g...

Embodiment 2

[0067] Add 28g of potassium permanganate, 28.7g of manganese nitrate hexahydrate, 8.5g of copper chloride dihydrate and 17.7g of cerium chloride hexahydrate in sequence in 786g of pure water, stir until fully dispersed and dissolved, and the speed of the mixer is 1000r / min , reacted at 100°C for 10min. The above mixed solution was transferred to a high-pressure reactor, set to react at 100°C for 30 hours, then taken out, washed and filtered, and then dried at 200°C for 2 hours to obtain the air purification composite catalyst precursor.

[0068] Mix the above-mentioned composite catalyst precursor, silica micropowder and clay uniformly according to the mass ratio of 1:0.5:2 to obtain composite granulated powder for use. Select 0.2mm silica particles and add them to the disc granulator at a rotational speed of 45r / min for granulation. Water is used as the binder during the granulation process. The added mass of the composite granulation powder and water The ratio is 1:0.3, and...

Embodiment 3

[0072] Add 31.6g of potassium permanganate, 17.8g of manganese sulfate tetrahydrate, 1.2g of copper nitrate trihydrate and 6.4g of cerium sulfate tetrahydrate into 285g of pure water in turn, stir until fully dispersed and dissolved, and the speed of the mixer is 150r / min. React at 20°C for 180min. The above mixed solution was transferred to a high-pressure reactor, set to react at 180°C for 2 hours, then taken out, washed and filtered, and then dried at 100°C for 20 hours to obtain the air purification composite catalyst precursor.

[0073] The above composite catalyst precursor, diatomaceous earth and clay are uniformly mixed according to the mass ratio of 1:0.2:1 to obtain composite granulated powder for use. Select 0.2mm zirconia particles and add them to the disc granulator, and the rotation speed is 10r / min for granulation. Water is used as the binder in the granulation process, and the mass ratio of composite granulation powder to water is The ratio is 1:0.45, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com