Method for growing copper-based multilayered graphene

A multi-layer graphene and copper-based technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems affecting the number and quality of graphene layers, difficult to obtain and widely used, high price of single crystal copper, etc. Achieve the effect of improving catalytic decomposition efficiency, simple and easy operation, and high multi-layer ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for growing copper-based multilayer graphene: take a copper foil with a purity of 99.8% and a thickness of 25 microns, put it into a polishing solution, and polish it for 60 seconds at a voltage of 5V. The polished copper foil was taken out, cleaned three times in ethanol and blown dry. Put the treated copper foil into the quartz holder.

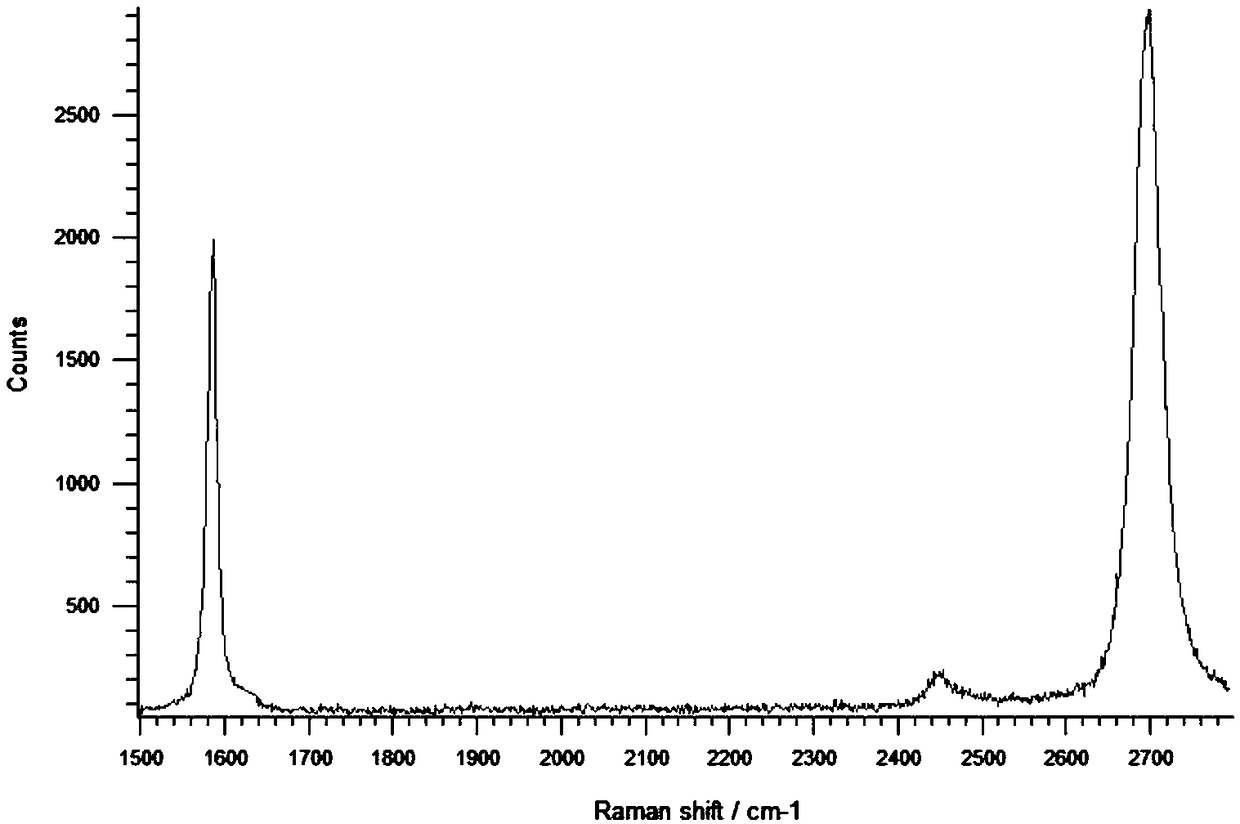

[0024] Take another piece of copper foil with a thickness of 18 μm and ultrasonically clean it with ethanol. This copper foil was carefully wrapped around the quartz holder and placed in the center of the atmosphere tube furnace. Argon was passed through the tube furnace for a period of time and then closed. Then pass hydrogen gas into the tube furnace and heat to 800° C. for 120 minutes for annealing. Continue to feed methane, stop heating after 60 minutes, and take out the quartz support after the tube furnace cools down to room temperature. Graphene grown on copper foil was characterized by scanning electron microscopy...

Embodiment 2

[0026] A method for growing copper-based multilayer graphene: take a copper foil with a purity of 99.8% and a thickness of 35 microns, put it into a polishing solution, and polish it for 60 seconds at a voltage of 5V. The polished copper foil was taken out, cleaned three times in ethanol and blown dry. Put the treated copper foil into the quartz holder.

[0027] Take another piece of nickel foil with a thickness of 18 μm and ultrasonically clean it with ethanol. This nickel foil was carefully wrapped around the quartz holder and placed in the center of the atmosphere tube furnace.

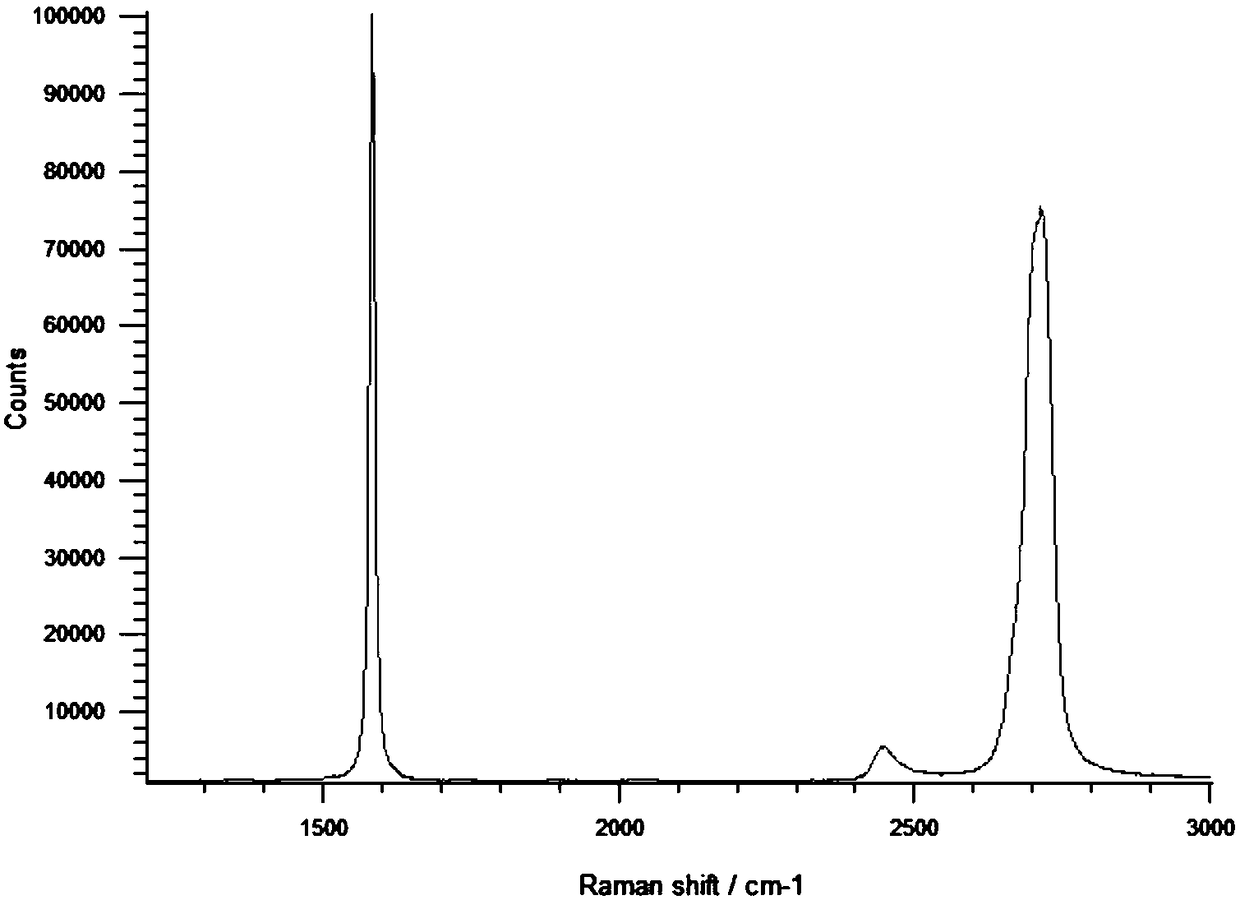

[0028] Nitrogen is passed through the tube for a period of time, then closed. Pass hydrogen into the tube and heat to 1100°C for 10 minutes for annealing. Continue to feed ethylene, keep it for 30 minutes, then stop heating, and take out the quartz support after the tube furnace cools down to room temperature. Graphene grown on copper foil was characterized by scanning electron microscopy and R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com