Impulse-type bionic power device based on single-component fuel and control method thereof

A power plant, pulsed technology, applied in fuel cells, fuel cell additives, reactant parameter control, etc., can solve difficult balance, noise, efficiency, pollution is difficult to break through, exoskeleton robots and jetpack endurance obstacles and other problems to achieve the effect of improving the reaction rate, high energy density, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

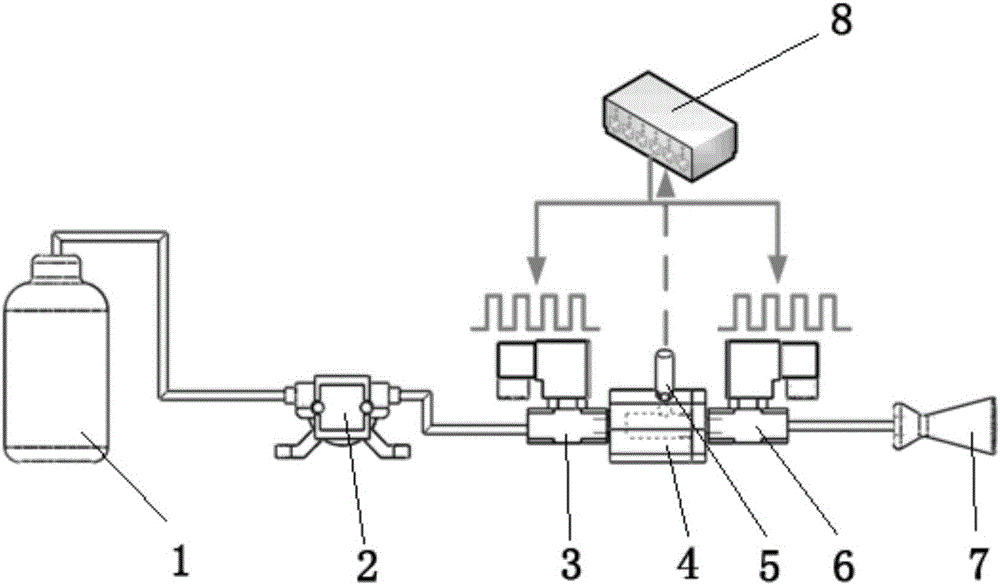

[0040] A specific design such as figure 1 The shown pulse type biomimetic power plant based on monocomponent fuel includes the following:

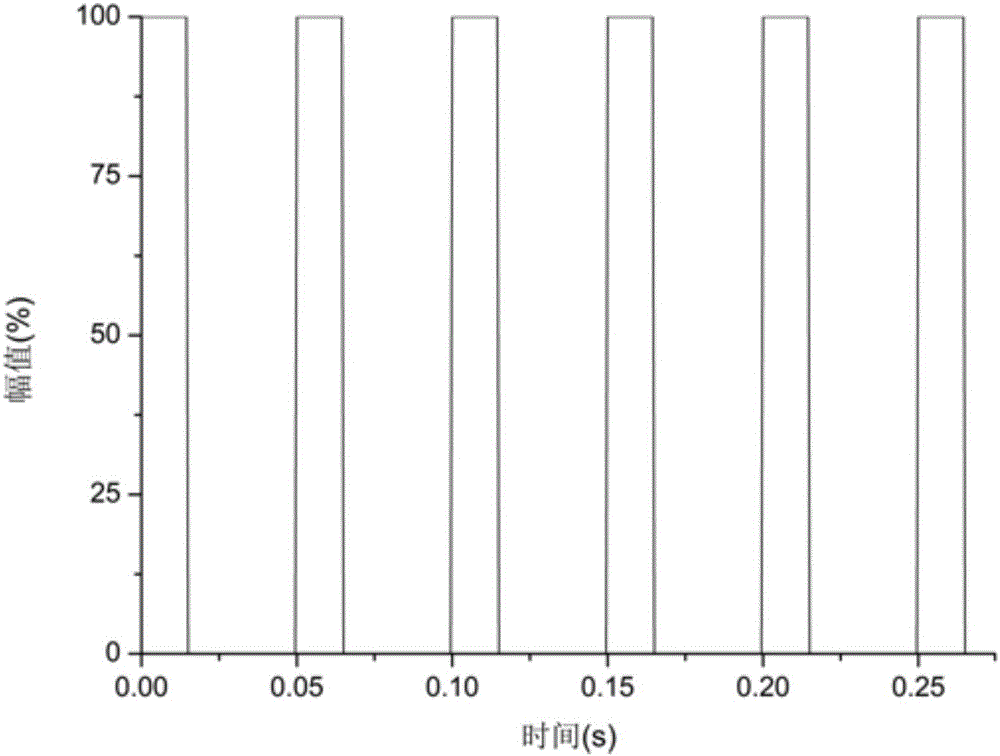

[0041] (1) The device includes a fuel supply system and a pulse reaction system. The fuel supply system includes a storage tank and a flow pump; the pulse reaction system includes an inlet high-frequency switching valve, a catalyst bed, a pressure sensor, an outlet high-frequency switching valve, and a PWM controller. ,nozzle. The storage tank is connected to the inlet of the catalyst bed through a flow pump, and the outlet of the catalyst bed is connected to the nozzle. The inlet and outlet of the catalyst bed are respectively equipped with an inlet high-frequency on-off valve and an outlet high-frequency on-off valve. A variable pressure sensor, the signal end of the pressure sensor is connected with the PWM controller, and the signal end of the PWM controller is connected with the inlet high-frequency switch valve, the outlet high-freq...

Embodiment 2

[0060] A specific design such as figure 1 The shown pulse type biomimetic power plant based on monocomponent fuel includes the following:

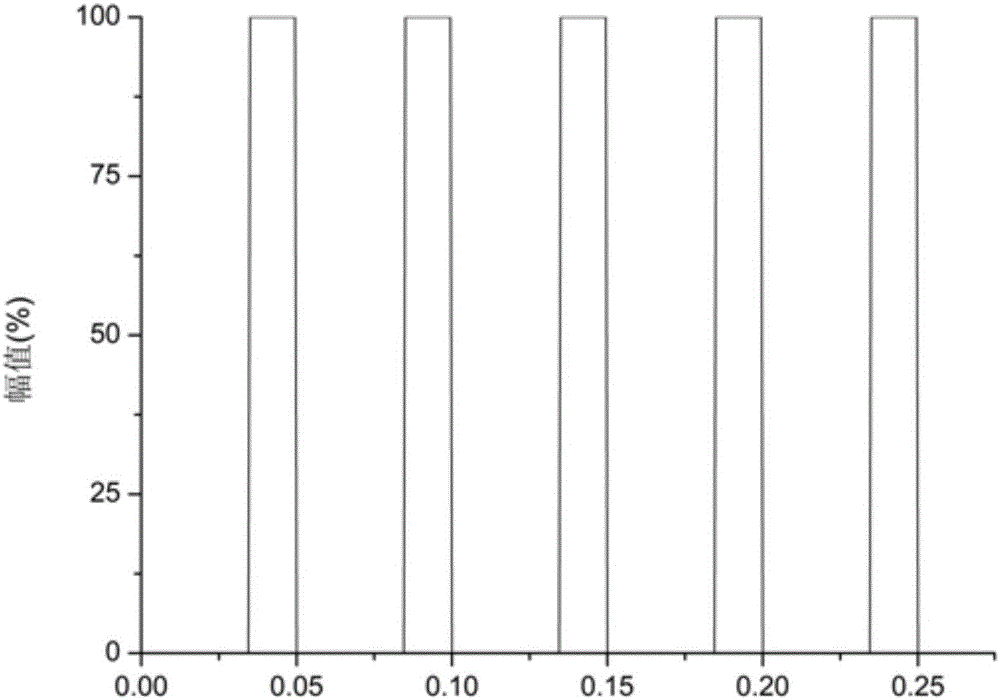

[0061] (1) The device includes a fuel supply system and a pulse reaction system. The fuel supply system includes a storage tank and a flow pump; the pulse reaction system includes an inlet high-frequency switching valve, a catalyst bed, a pressure sensor, an outlet high-frequency switching valve, and a PWM controller. ,nozzle. The storage tank is connected to the inlet of the catalyst bed through a flow pump, and the outlet of the catalyst bed is connected to the nozzle. The inlet and outlet of the catalyst bed are respectively equipped with an inlet high-frequency on-off valve and an outlet high-frequency on-off valve. A variable pressure sensor, the signal end of the pressure sensor is connected with the PWM controller, and the signal end of the PWM controller is connected with the inlet high-frequency switch valve, the outlet high-freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com