Harmless decomposition method for chlorine absorption product NaClO

A chlorine gas and product technology, applied in the field of harmless decomposition of chlorine gas absorption product NaClO, can solve the problems of toxic chlorine gas, chlorine gas leakage, secondary pollution, etc., and achieve the effect of efficient catalytic decomposition, simple structure and unique conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0027] Example.

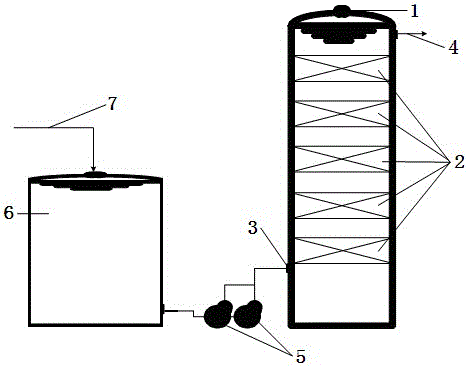

[0028] see figure 1 , the equipment used in the harmless decomposition method of chlorine gas absorption product NaClO comprises NaClO decomposition tower 1, flow control pump 5, liquid storage tank 6, chlorine gas inlet pipeline 7 and PLC control system, in the NaClO decomposition tower 1 in the present embodiment There are at least two layers of catalyst trays 2, each catalyst tray 2 is filled with a catalyst, the catalyst is mixed with manganese dioxide and a synergist in any ratio, and the synergist is copper oxide, iron oxide, nickel oxide and One or two or more mixtures mixed in any ratio in cobalt oxide, the bottom and top of the NaClO decomposition tower 1 are respectively provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com