Composite material for catalyzing formaldehyde decomposition and preparation method thereof

A composite material and formaldehyde decomposition technology, applied in separation methods, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of inconvenience and high cost, and achieve the effects of long service life, stable performance and high catalytic decomposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

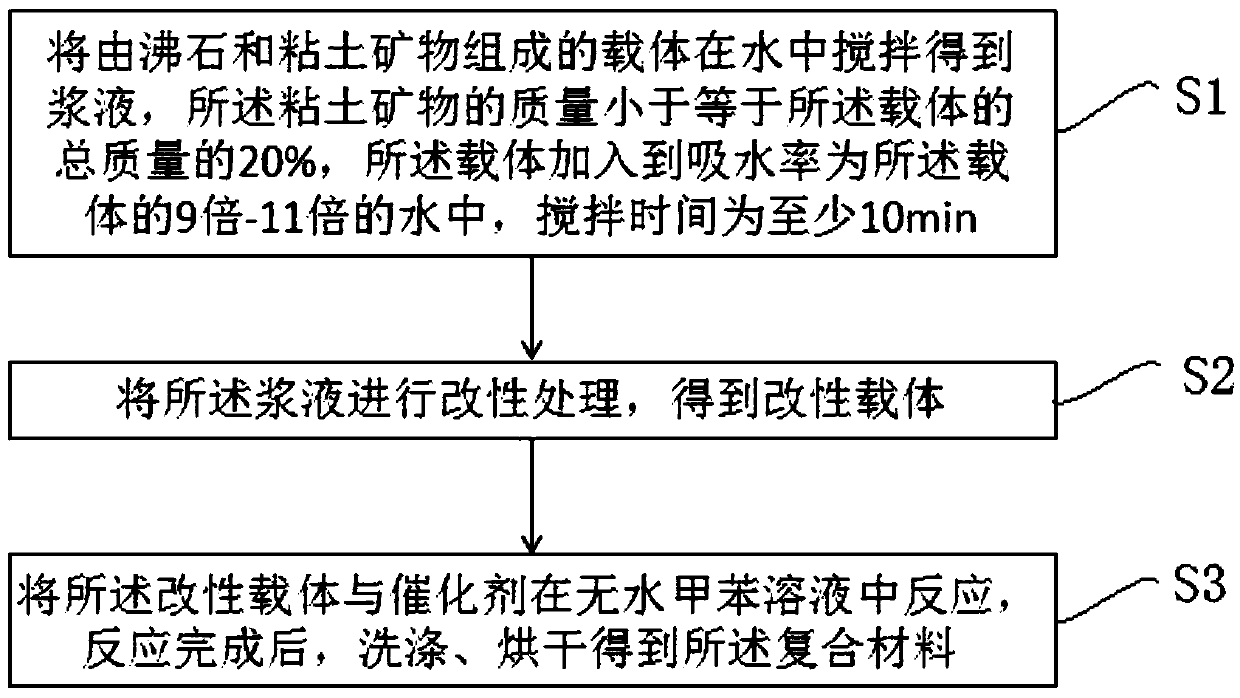

[0034] like figure 1 Shown, according to the preparation method of the composite material for catalytic formaldehyde decomposition of the embodiment of the present invention, comprises the following steps:

[0035] S1. Stir the carrier composed of zeolite and clay mineral in water to obtain a slurry. The quality of the clay mineral is less than or equal to 20% of the total mass of the carrier. The carrier is added to water with a water absorption rate of 9-11 times that of the carrier. The stirring time is at least 10min;

[0036] S2, modifying the slurry to obtain a modified carrier;

[0037] S3, reacting the modified carrier and the catalyst in anhydrous toluene solution, after the reaction is completed, washing and drying to obtain a composite material.

[0038] That is to say, the carrier may be composed of zeolite and clay minerals, wherein the mass of the clay minerals may be less than or equal to 20% of the total mass of the carrier. The carrier can be added to water...

Embodiment 1

[0063] Firstly, the carrier composed of zeolite and clay minerals is added into water whose water absorption rate is 10 times that of the carrier and stirred for 10 minutes to obtain a slurry.

[0064] Next, add tetrabutyl titanate into absolute ethanol whose mass is 5 times its mass and stir for 30 minutes. After stirring and mixing evenly, add it dropwise into the slurry to react for 1 hour. After the reaction, dry it at 120°C to obtain composite carrier B. The obtained composite carrier B was dispersed into an aqueous ethanol solution whose water absorption rate was 10 times that of 50% by mass. After the composite carrier B is evenly dispersed, add the coupling agent KH550 to react. The reaction process is kept at 55°C and under acidic conditions with a pH of 3. The reaction time is 6 hours. After the reaction, it is dried at 120°C to obtain the modification carrier.

[0065] Finally, react the modified carrier obtained from the above reaction with the catalyst in anhydro...

Embodiment 2

[0067] Firstly, the carrier composed of zeolite and clay minerals is added into water whose water absorption rate is 9 times that of the carrier and stirred for 15 minutes to obtain a slurry.

[0068] Next, add tetrabutyl titanate into absolute ethanol whose mass is 4 times its mass and stir for 40 minutes. After stirring and mixing evenly, add it dropwise into the slurry to react for 2 hours. After the reaction, dry it at 110°C to obtain composite carrier B. The obtained composite carrier B was dispersed into an aqueous ethanol solution with a water absorption rate 9 times its water absorption rate and a mass percent of 40. After the composite carrier B is evenly dispersed, add the coupling agent KH550 to react. The reaction process is kept at 50°C and under acidic conditions with a pH of 2. The reaction time is 7 hours. After the reaction, it is dried at 110°C to obtain the modified carrier.

[0069] Finally, react the modified carrier obtained by the above reaction with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com