Multifunctional steel-slag ecological environment-friendly water-permeable brick and preparation method thereof

A permeable brick and multi-functional technology, applied in the field of comprehensive utilization of solid waste resources, can solve the problems of low water permeability, poor stability, low steel slag content, etc., and achieve both water permeability and wear resistance, low production cost, The effect of high slag content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

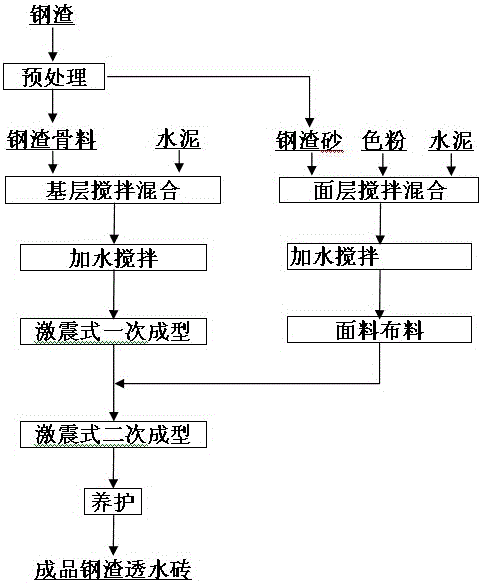

Method used

Image

Examples

Embodiment 1

[0034] A. Steel slag pretreatment: use steel slag with f-CaO (free calcium oxide) content of 6%, the accumulation thickness is less than 0.5m, the average amount of ultraviolet radiation outdoors is 5000 MJ / square meter, and the number of daily sun exposure is 150 hours per month The site is exposed to the sun and watered once a day to ensure that all the bricks are soaked for 2 months; the steel slag after being exposed to the sun is screened into steel slag powder of 10mm steel slag gravel;

[0035] B, batching: carry out batching according to the raw material of following parts by weight:

[0036] Base: 70 parts of steel slag aggregate, 20 parts of mineral powder, 10 parts of water;

[0037] Surface layer: 75 parts of steel slag sand, 16 parts of cement, 6 parts of water, 2 parts of toner;

[0038] Wherein, the steel slag aggregate is mixed with one or more of steel slag powder 10mm, so that Become a steel slag material with a particle size > 1.25mm and a proportion > 80%...

Embodiment 2

[0045]A. Steel slag pretreatment: Use steel slag with 3% f-CaO (free calcium oxide) content, pile up thickness of 0.5m, and carry out in a site with an average outdoor ultraviolet radiation of 4000 MJ / m2 and a monthly sun exposure of 120 hours Expose to the sun and water once a day to ensure that all the bricks are soaked for one month; the steel slag after being exposed to the sun on the site is sieved into steel slag powder of 10mm steel slag gravel;

[0046] B, batching: carry out batching according to the raw material of following parts by weight:

[0047] Base: 90 parts of steel slag aggregate, 8 parts of mineral powder, 5 parts of water;

[0048] Surface layer: 85 parts of steel slag sand, 10 parts of cement, 5 parts of water;

[0049] Wherein, the steel slag aggregate is mixed with one or more of steel slag powder 10mm, so that Become a steel slag material with a particle size > 1.25mm and a proportion > 80%;

[0050] The steel slag sand is the steel slag material ob...

Embodiment 3

[0056] A. Steel slag pretreatment: use steel slag with f-CaO (free calcium oxide) content of 4%, the accumulation thickness is less than 0.5m, the average amount of ultraviolet radiation outdoors is more than 4500 MJ / square meter, and the monthly sun exposure is 130 hours The above sites are exposed to the sun and watered once a day to ensure that all the bricks are soaked for 3 months; the steel slag after being exposed to the sun is screened into steel slag powder of 10mm steel slag gravel;

[0057] B, batching: carry out batching according to the raw material of following parts by weight:

[0058] Base: 80 parts of steel slag aggregate, 10 parts of cement, 8 parts of water;

[0059] Surface layer: 80 parts of steel slag sand, 20 parts of cement, 10 parts of water, 1 part of toner;

[0060] Wherein, the steel slag aggregate is mixed with one or more of steel slag powder 10mm, so that Become a steel slag material with a particle size > 1.25mm and a proportion > 80%;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com