Composite metal catalyst for online hydrocarbon removal instrument and preparation method thereof

A composite metal and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalytic efficiency of catalysts, and achieve the effect of improving catalytic decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

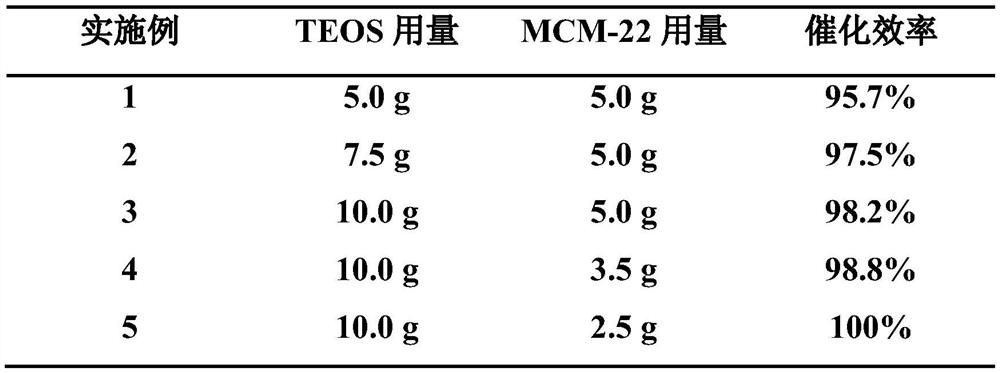

Embodiment 1

[0021] Dissolve 3.5g template agent, 0.025mol Pd(NO3)2·6H2O and 0.025mol RuCl3·3H2O in 10ml ethylene glycol, and slowly add ethylenediamine solution dropwise to the solution. After mixing uniformly, it is heated by microwave radiation, cooled to room temperature and washed with distilled water to obtain Pdx / Ruy and dried. Put the obtained Pdx / Ruy into a 500mL flask and add 250ml of ethanol, 50ml of purified water, 10g of CTMAB, 5.0g of TEOS, add dropwise ammonia at 45°C and stir for 6 hours, then filter the mixture and wash with water. It was vacuum dried at ℃, and finally calcined in a muffle furnace at 600℃ for 5 hours to obtain PdxRuy / SiO2 nanoparticles. Treat 5.0g PdxRuy / SiO2 nanoparticles, 5.0g MCM-22 and deionized water on a ball mill for 1.5-3 hours to prepare a molecular sieve water slurry. Then, under vacuum, evenly cover the Zeolite surface with the molecular sieve slurry. Finally, it was dried in a vacuum drying oven at 70°C, and then calcined in a muffle furnace a...

Embodiment 2

[0023] Dissolve 3.5g template agent, 0.025mol Pd(NO3)2·6H2O and 0.025mol RuCl3·3H2O in 10ml ethylene glycol, and slowly add ethylenediamine solution dropwise to the solution. After mixing uniformly, it is heated by microwave radiation, cooled to room temperature and washed with distilled water to obtain Pdx / Ruy and dried. Put the obtained Pdx / Ruy into a 500mL flask and add 250ml of ethanol, 50ml of purified water, 10g of CTMAB, 7.5g of TEOS, add dropwise ammonia at 45°C and stir for 6 hours, then filter the mixture, wash with water, It was vacuum dried at ℃, and finally calcined in a muffle furnace at 600℃ for 5 hours to obtain PdxRuy / SiO2 nanoparticles. Treat 5.0g PdxRuy / SiO2 nanoparticles, 5.0g MCM-22 and deionized water on a ball mill for 1.5-3 hours to prepare a molecular sieve water slurry. Then, under vacuum, evenly cover the Zeolite surface with the molecular sieve slurry. Finally, it was dried in a vacuum drying oven at 70°C, and then calcined in a muffle furnace at 5...

Embodiment 3

[0025] Dissolve 3.5g template agent, 0.025mol Pd(NO3)2·6H2O and 0.025mol RuCl3·3H2O in 10ml ethylene glycol, and slowly add ethylenediamine solution dropwise to the solution. After mixing uniformly, it is heated by microwave radiation, cooled to room temperature and washed with distilled water to obtain Pdx / Ruy and dried. Put the obtained Pdx / Ruy into a 500mL flask and add 250ml of ethanol, 50ml of purified water, 10g of CTMAB, 10.0g of TEOS, add dropwise ammonia at 45°C and stir for 6 hours, then filter the mixture and wash with water. Vacuum drying at ℃, and finally calcination in a muffle furnace at 600 ℃ for 5 hours to obtain PdxRuy / SiO2 nanoparticles. Treat 5.0g PdxRuy / SiO2 nanoparticles, 5.0g MCM-22 and deionized water on a ball mill for 1.5-3 hours to prepare molecular sieve water slurry. Then, under vacuum, evenly cover the Zeolite surface with the molecular sieve slurry. Finally, it was dried in a vacuum drying oven at 70°C, and then calcined in a muffle furnace at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com