Coal flue gas mercury adsorbing removal process capable of recovering adsorbent and device utilizing same

A technology of coal-burning flue gas and adsorbent, which is applied in the field of flue gas purification, can solve the problems that activated carbon cannot be recycled and reused, the quality of finished bricks or cement is reduced, and the amount of adsorbent is increased, and achieves significant selective adsorption of mercury. Effect of improving stability and improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Working process of active carbon adsorption and demercuration and desorption recovery system

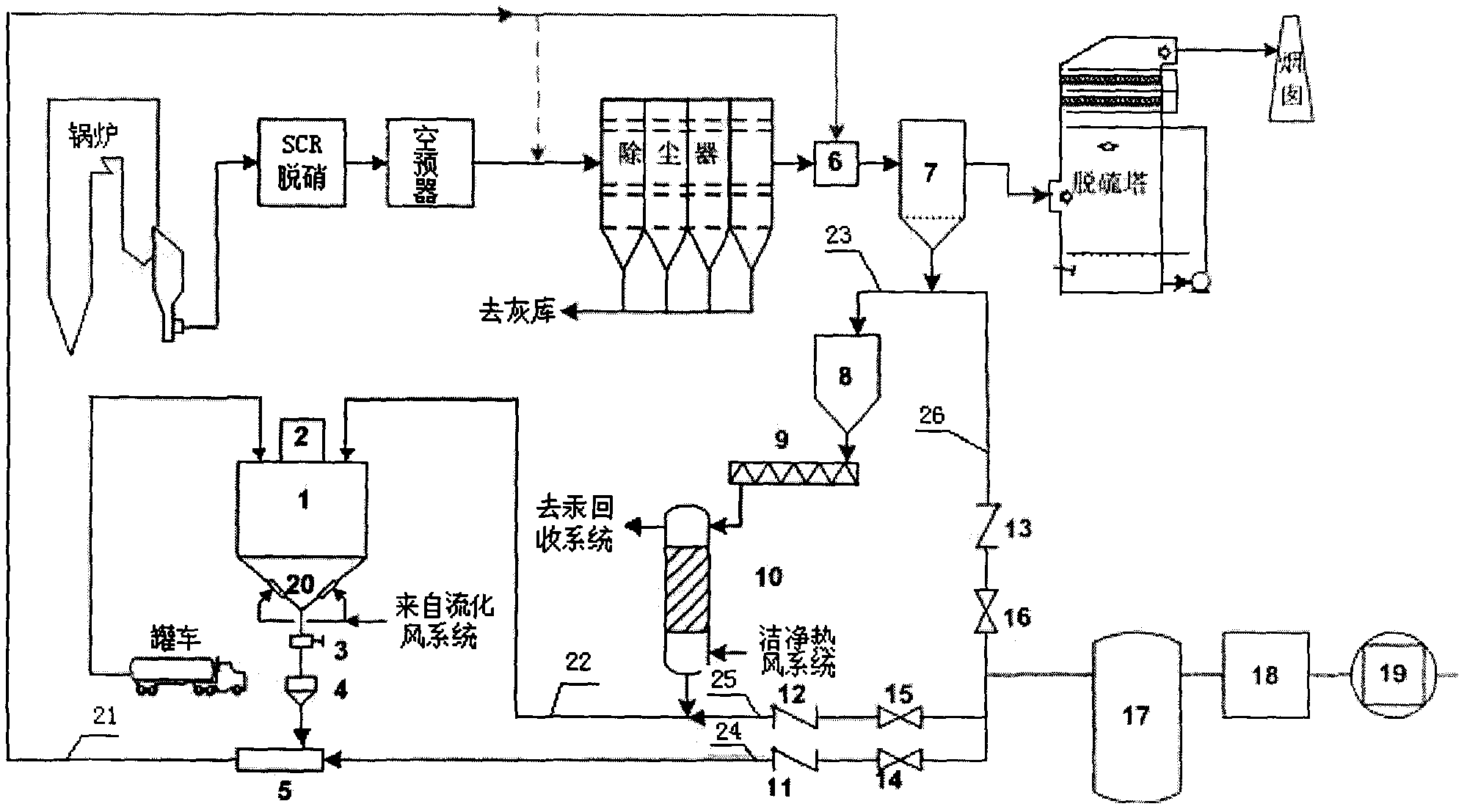

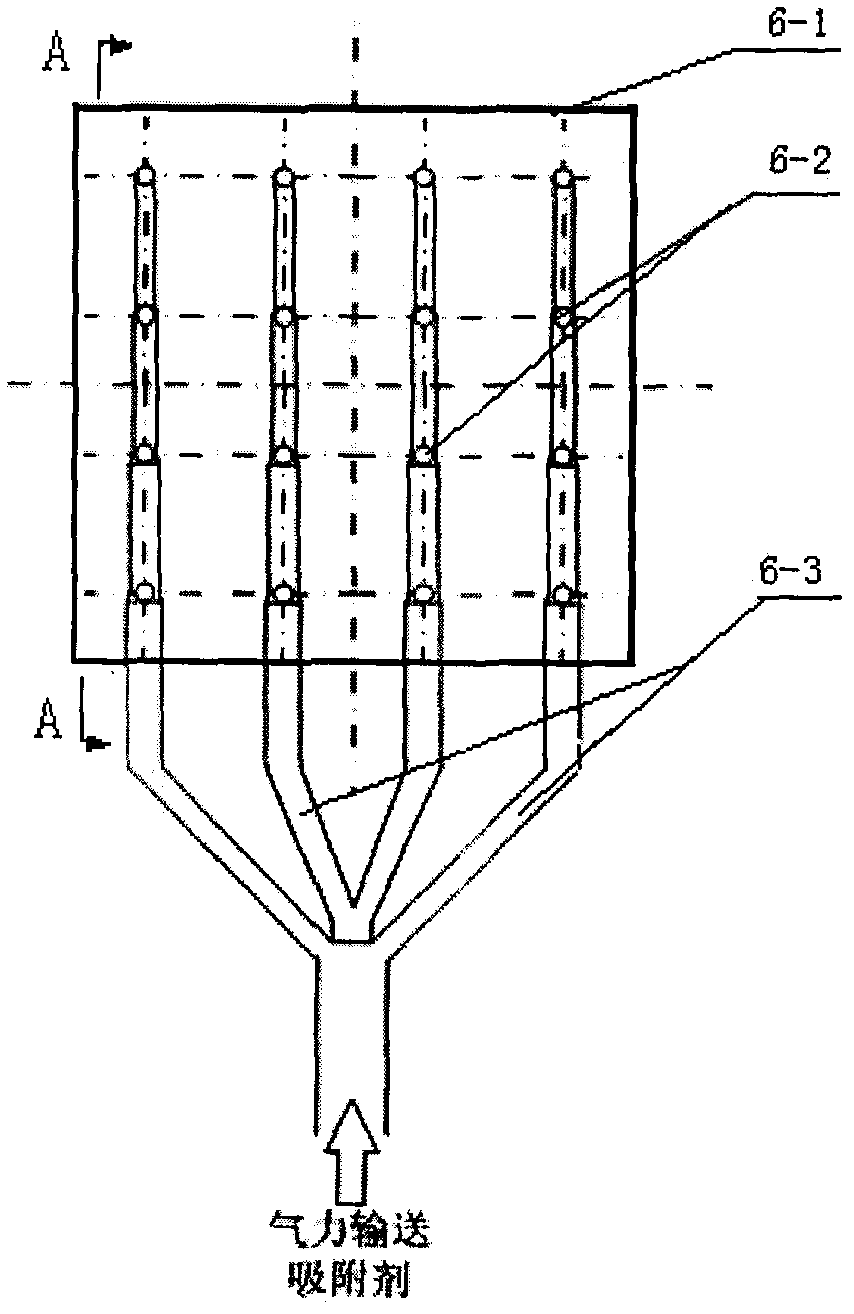

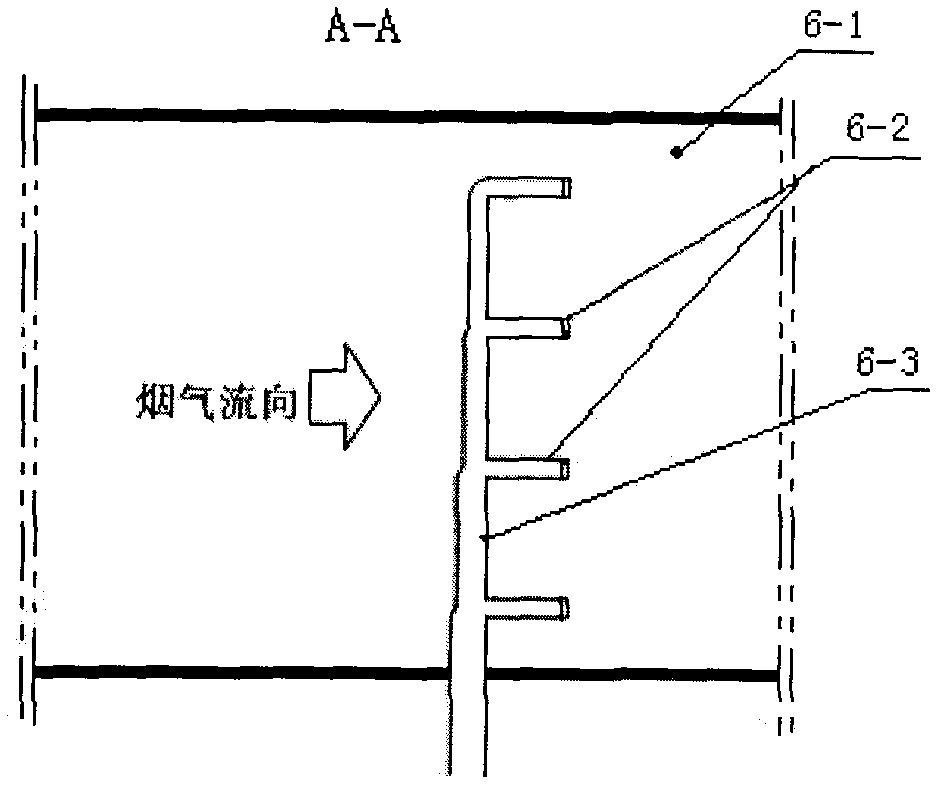

[0022] figure 1 It is a flue gas purification treatment system process including selective catalytic reduction denitrification (SCR denitrification), dust removal, adsorption demercuration and desulfurization. The working process of the adsorption demercuration system is as follows:

[0023] Open the air compressor 19, the compressed air enters the air storage tank 17 after removing oil, water and dust through the degreasing water device 18, the compressed air system throws automatically, and the gas storage is standby. Turn on the fluidizing air system, so that the air flow is blown upward from the fluidizing air inlet 20 at the bottom of the adsorbent storage bin 1, and at the same time open the bag filter 2 on the top of the warehouse; the fluidizing wind can make the activated carbon near the feeding port fluidized (ie suspended ) state, to prevent the activated...

Embodiment 2

[0026] Example 2 Experiments on mercury removal efficiency of flue gas adsorbents with different dust contents

[0027] In this test, the injection position of activated carbon includes two schemes: after the boiler flue gas dust collector and before the dust collector, and the scheme of spraying after the dust collector includes three dust removal situations with the electric field numbers of 4, 3 and 1 respectively. , that is, the soot concentration of the outlet flue gas increases with the reduction of the number of electric fields used by the dust collector; the spraying scheme before the dust collector includes high dust (21270mg / Nm 3 ) and low dust (12370Nm 3 ) two concentrations, the comparison of activated carbon mercury removal efficiency under different conditions is shown in Table 1,

[0028] Table 1

[0029]

[0030]

[0031] As can be seen from Table 1, the mercury removal efficiency of the adsorbent has a great relationship with the soot concentration in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com