Two types of pH sensitive regenerated polymers and preparation method thereof, as well as regenerated aqueous two-phase system formed by pH sensitive regenerated polymers and application of regenerated aqueous two-phase system

A polymer and polymerization reaction technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of increasing the industrial cost of the two-water phase, which is not conducive to the promotion of the two-water phase technology, and is suitable for large-scale promotion and application, efficient recovery, recycling The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

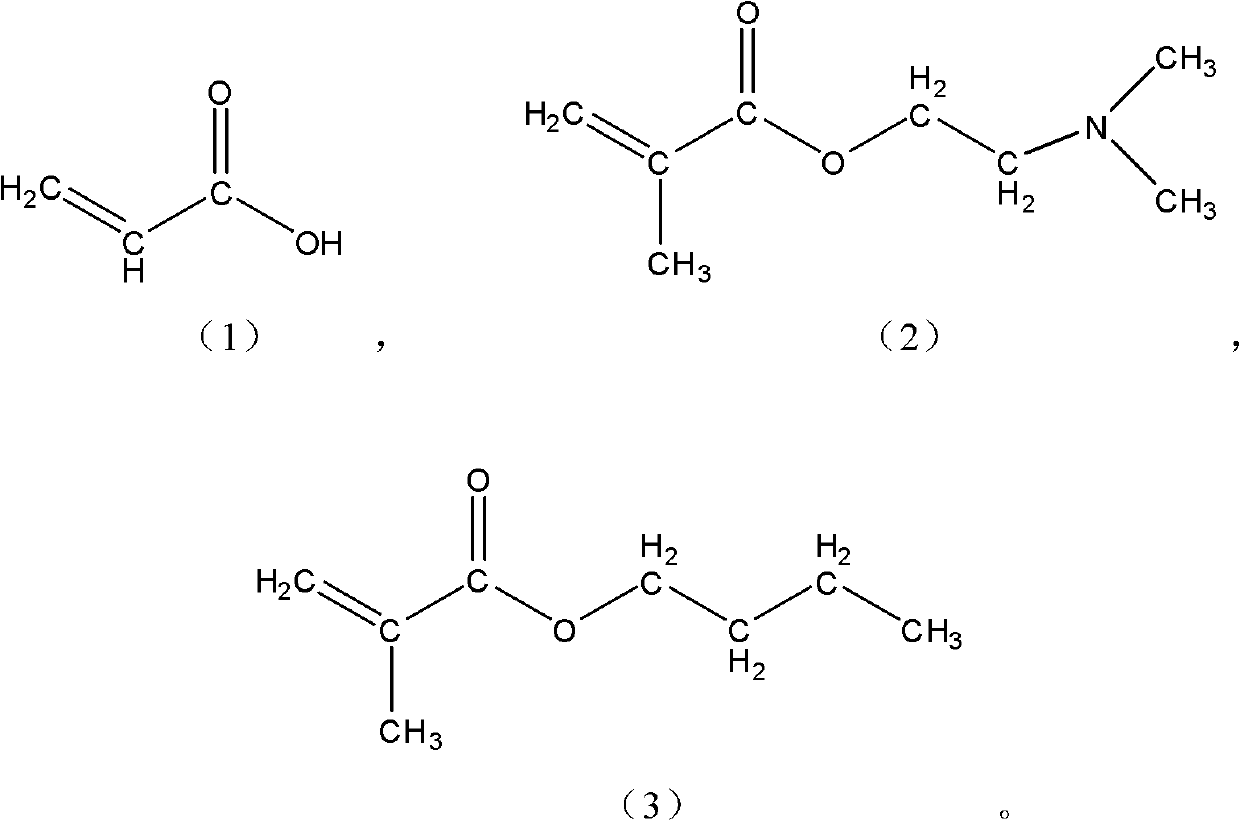

[0024] Example 1 pH sensitive regenerative polymer P ADB preparation

[0025] In a 250ml Erlenmeyer flask with a stopper, add 120ml of deionized water with a pH of 7.0, 5ml of acrylic acid, 1ml of dimethylaminoethyl methacrylate, and 0.5ml of butyl methacrylate (the molar ratio is 23:2:1), and add Initiator sodium bisulfite, ammonium persulfate each 0.1235g, shake well to dissolve. Infuse nitrogen gas for 10-15 minutes to ensure that there is only inert gas in the conical flask. Seal the mouth of the Erlenmeyer flask with a self-sealing tape, place it in a water-bath shaker at 55°C, and vibrate at 200rpm for 24h. After the reaction, the white colloidal solid at the bottom of the flask was taken out, washed with ethanol and acetone, and dried in a vacuum oven. The white solid of drying gained is polymer P of the present invention ADB . according to 1 HNMR determination of polymer P ADB The actual molar ratio of the three monomers is 8.04:0.58:0.47, and the polymer P is d...

Embodiment 2

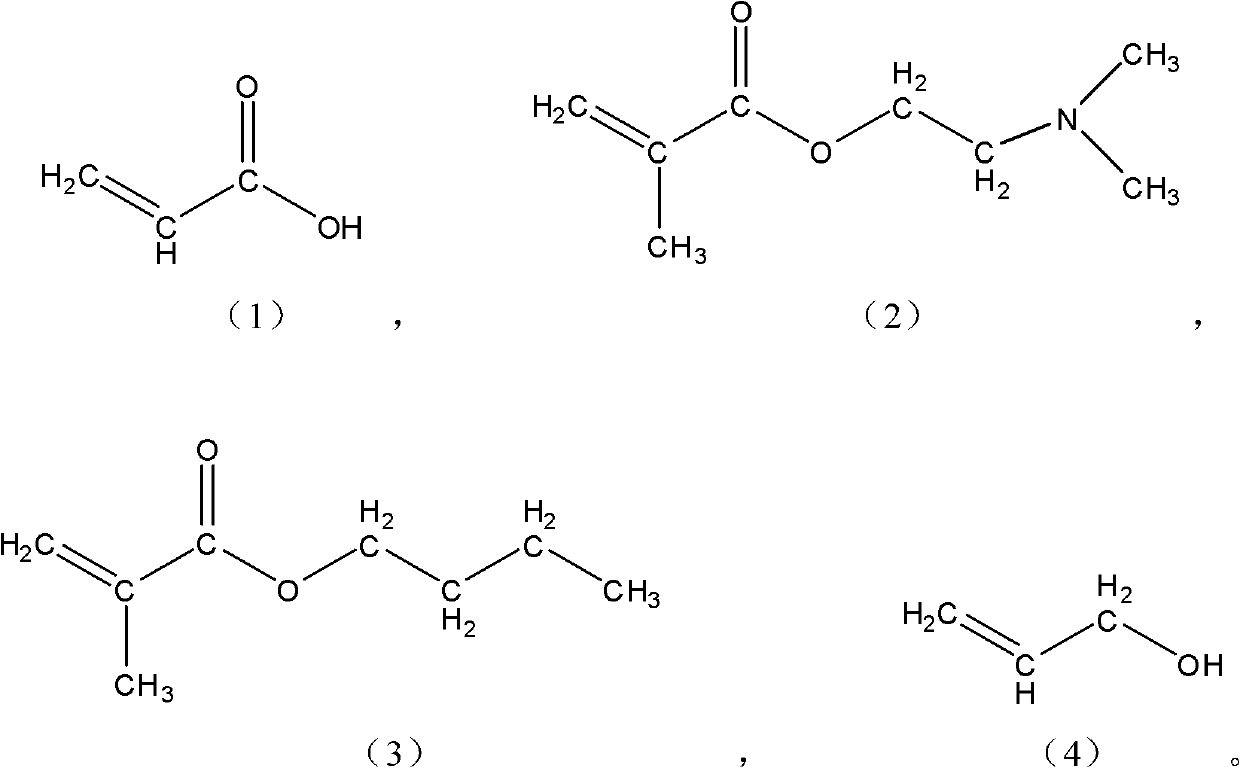

[0026] Example 2 pH sensitive regenerative polymer P ADBA preparation

[0027] In a 250ml Erlenmeyer flask with a stopper, add 120ml of deionized water with a pH of 7.0, add 5ml of acrylic acid, 4ml of dimethylaminoethyl methacrylate, 0.5ml of butyl methacrylate, and 1.284ml of propylene alcohol (the molar ratio is 23: 8:1:6), add 0.1235g each of initiator sodium bisulfite and ammonium persulfate, shake well to dissolve. Infuse nitrogen gas for 10-15 minutes to ensure that there is only inert gas in the conical flask. Seal the mouth of the Erlenmeyer flask with a self-sealing tape, place it in a water-bath shaker at 55°C, and vibrate at 200rpm for 24h. After the reaction, the white colloidal solid at the bottom of the flask was taken out, washed with ethanol and acetone, and dried in a vacuum oven. The white solid of drying gained is polymer P of the present invention ADBA . according to 1 HNMR determination of polymer P ADBA The actual molar ratio of the above-mentione...

Embodiment 3

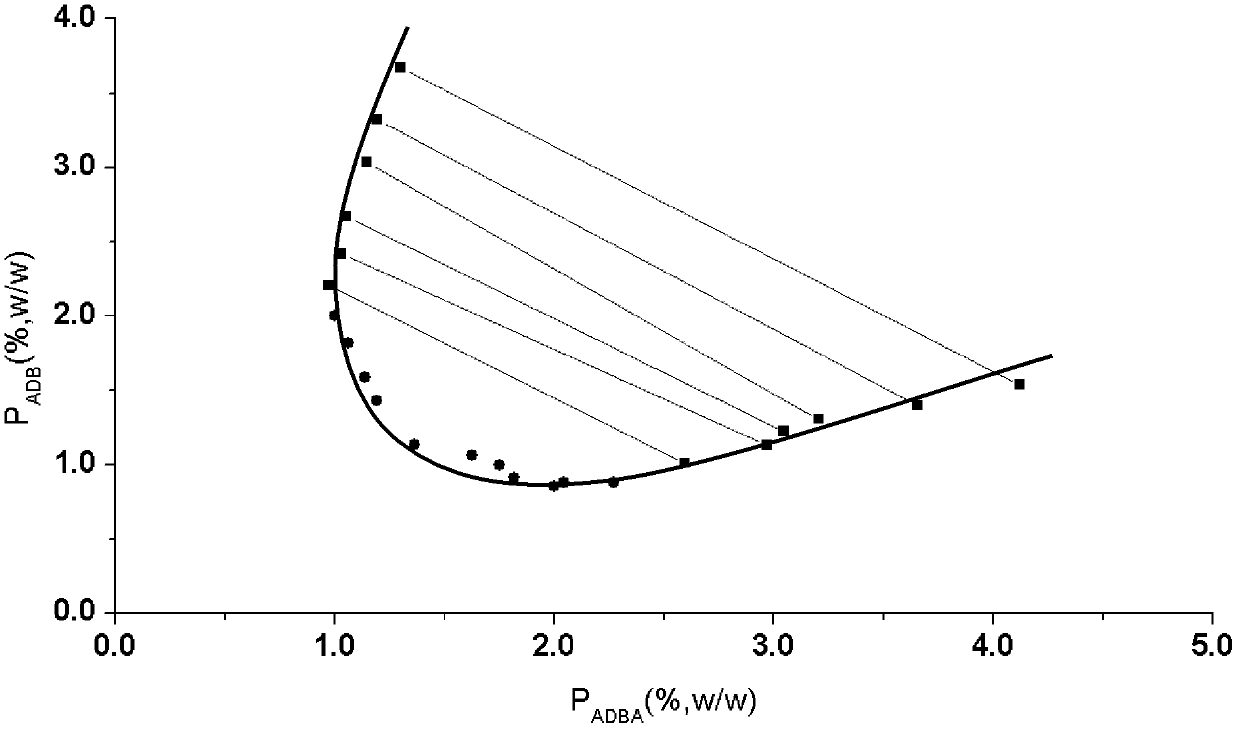

[0028] Example 3 Polymer P ADB and polymer P ADBA recovery experiment

[0029] First weigh the empty centrifuge tube thimble. A 1.25% (w / w) polymer solution was added to the centrifuge tube sleeve, and 0.3 mol / L HCl was added dropwise to adjust the pH until solids were precipitated and the solution became turbid. Continue to add HCl dropwise until the precipitate is completely separated, settles, and the supernatant becomes clear. Measure the pH value of the solution at this time, which is the isoelectric point. Put the centrifuge tube casing into a high-speed centrifuge and centrifuge for 30min at a rotation speed of 10000rpm. After centrifugation, the supernatant was discarded and dried in a vacuum oven until constant weight. After drying, measure the weight of the centrifuge tube casing again, and the difference before is the quality of the recovered polymer. It was determined that the polymer P ADBA The isoelectric point is 3.91, the recovery rate reaches 97.18%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com