Composite thin film integrating photothermal conversion performance and adsorption characteristics as well as preparation and application of composite thin film

A technology of photothermal conversion and adsorption characteristics, applied in heat exchange materials, adsorbed water/sewage treatment, alkali metal compounds, etc., can solve problems such as difficult heavy metal ion purification, improve multiple purification effects, and facilitate large-scale production and preparation , the effect of accelerating the adsorption purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of film with both light-to-heat conversion and adsorption functions

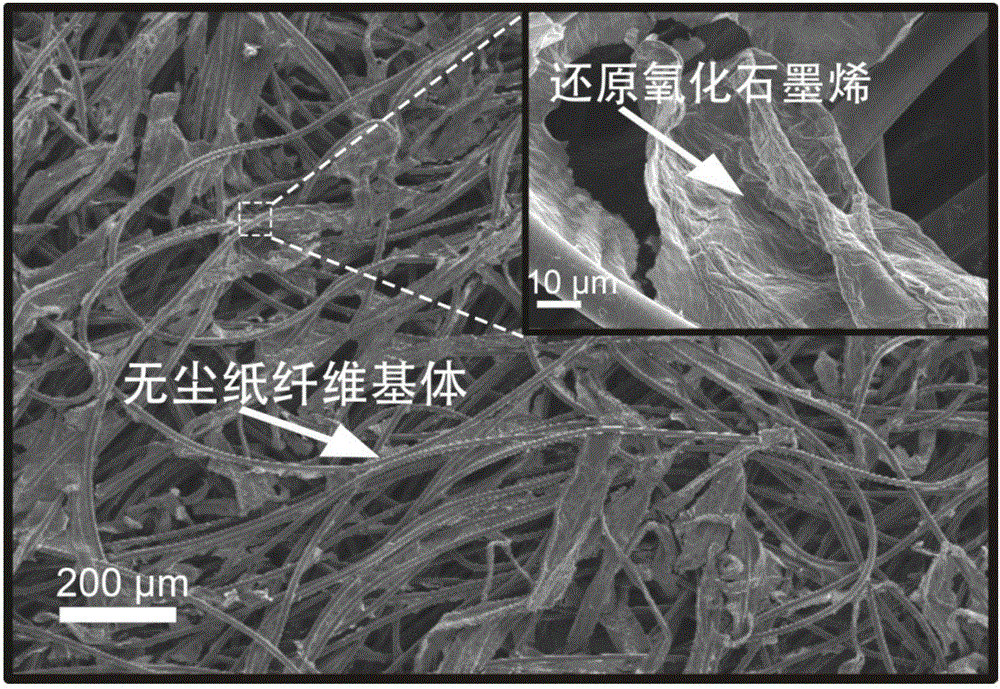

[0030] First, use the Hummers method to prepare a graphene oxide aqueous solution, prepare a 1mg / ml graphene oxide aqueous solution, take 1ml of the graphene oxide aqueous solution and drop it on the surface of a dust-free paper with a diameter of 2.5cm, and place it in an oven at 60°C. Dry to make graphene oxide dust-free paper. Graphene oxide on the surface of dust-free paper was reduced by hydrothermal method. Inject 20ml of distilled water and 10ml of ethanol into the inner tank of the high-pressure reactor, put the graphene oxide dust-free paper into the inner tank and seal it, keep it in a 120°C oven for 3 hours, cool down, take it out, and place it in a 60°C oven until it is dried . prepared as figure 1 Composite film composed of reduced graphene oxide and dust-free paper substrate is shown.

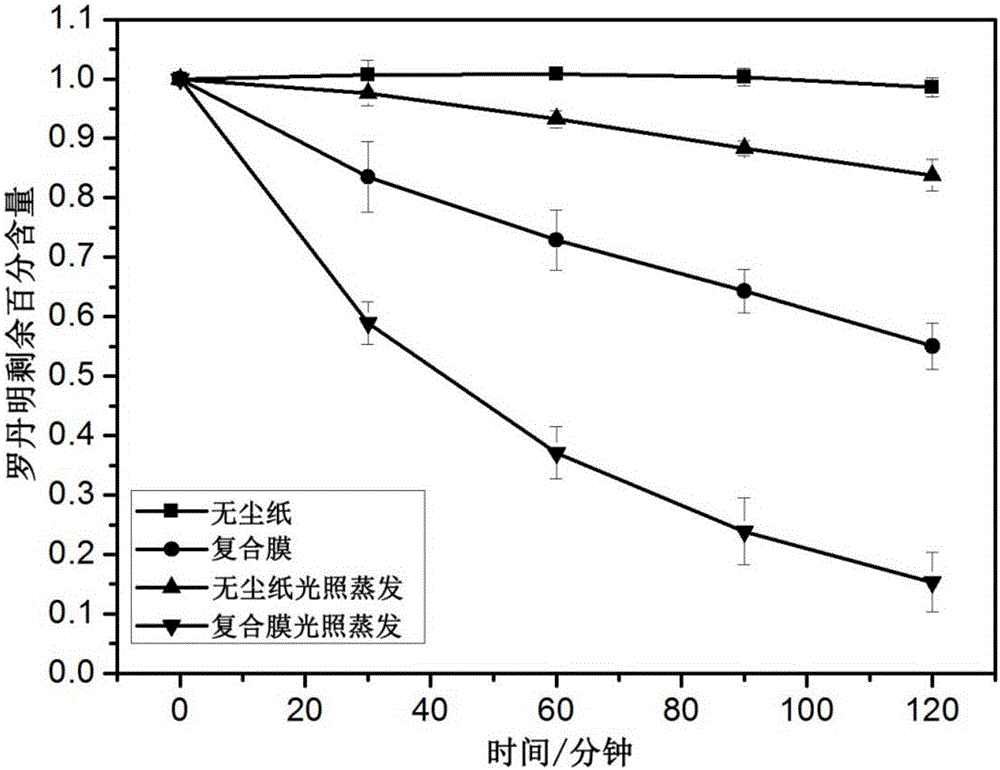

[0031] (2) Utilize the composite film prepared above to carry out pollutant adsorp...

Embodiment 2

[0036] A method for accelerating adsorption and purification by utilizing the photothermal effect of solar energy, the method comprising the following steps:

[0037](1) Preparation of film with both light-to-heat conversion and adsorption functions: a dust-free paper film with a porous micron structure is used as a substrate, and a layer of sheet-like carbon black nanopowder with both light-to-heat conversion and adsorption properties is deposited on the substrate template Prepared as a film with both light-to-heat conversion and adsorption functions. Specifically: uniformly disperse flaky carbon black powder with a sheet diameter of 50-200nm, which has both photothermal conversion and adsorption properties, into ethanol to obtain a solution with a mass concentration of 1-100mg / ml, and use physical deposition in the absence of A carbon black powder film is deposited on the base film of the dust paper to obtain a film with both light-to-heat conversion and adsorption functions...

Embodiment 3

[0040] The base film with a porous structure is a sponge; the substance with both photothermal conversion and adsorption properties is carbon nanotubes; the photothermal evaporation film is prepared by a spraying process: it will have both photothermal conversion and adsorption properties The substance with adsorption properties is that carbon nanotubes are evenly dispersed in ethanol (mass concentration is 1-100mg / ml), and a film with both photothermal conversion and adsorption functions is formed on the dust-free paper substrate through a spray pen device. All the other are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com