Protection device and protection method for cable sheath in power construction process

A protection device and electric power construction technology, which is applied in the direction of cable installation device, cable installation, electrical components, etc., can solve the problems of easy twisting of wires, easy twisting and entanglement, time-consuming and labor-intensive movement and recycling, etc., to achieve convenience Move or recycle, easy to release torsion force, drag and save time and effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

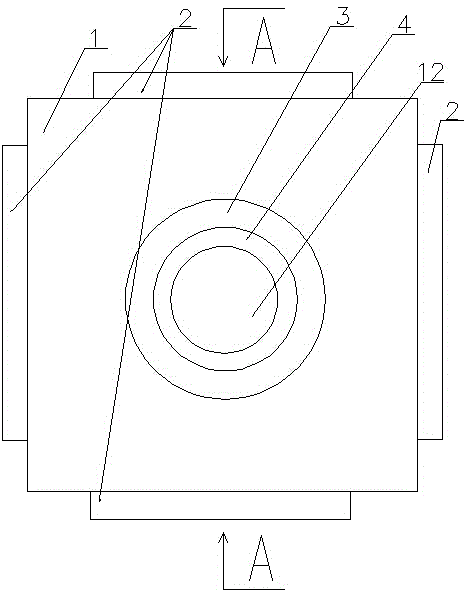

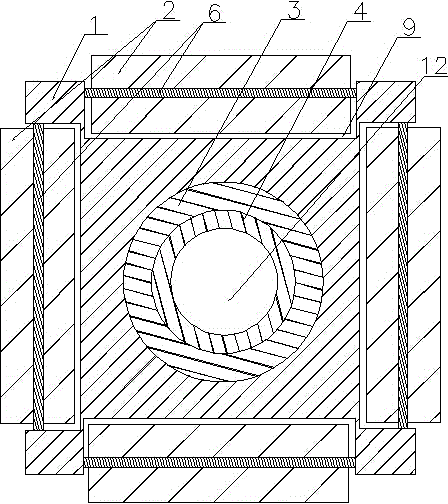

[0031] Embodiment 1: as figure 1 , 2 , 3, 4, 5, and 7, a cable sheath protection device in the electric power construction process, including a housing 1, the upper end of the housing 1 is provided with at least one rolling mechanism, and the housing 1 is provided with A through hole 12 perpendicular to the axial direction of the rotating shaft 6 of the rolling mechanism, the through hole 12 is provided with a bearing 3, and the inner tube 4 is sleeved in the bearing 3, and the two ends of the inner tube 4 protrude from the through hole, so Both ends of the inner tube 4 are provided with wire adjustment and fixing mechanisms.

[0032] The rolling mechanism includes a groove 9 and a rotating shaft 6 arranged on the upper end of the housing, the rotating shaft 6 is located on the upper part of the groove 9 so that a part of the roller 2 sleeved on the rotating shaft is located outside the groove 9 .

[0033] A bearing 3 is inlaid in the through hole 12 , and the bearing 3 is ...

Embodiment 2

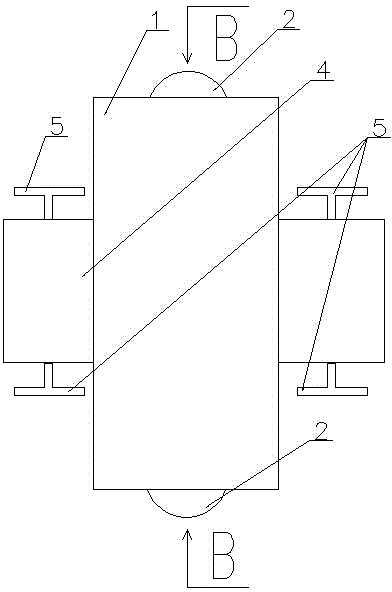

[0045] Embodiment 2: as figure 1 As shown, a cable sheath protection device in the electric power construction process includes a housing 1, the upper end of the housing 1 is provided with at least one rolling mechanism, and the housing 1 is provided with a rotating shaft 6 axial to the rolling mechanism. Perpendicular to the through hole 12, the bearing 3 is arranged in the said through hole 12, the inner tube 4 is sleeved in the bearing 3, the two ends of the inner tube 4 protrude from the through hole, and the two ends of the inner tube 4 are provided with Wire adjustment fixing mechanism.

[0046] A bearing 3 is inlaid in the through hole 12 , and the bearing 3 is sleeved on the inner tube 4 so that the inner tube 4 is connected to the housing 1 in rotation.

[0047] The wire adjustment and fixing mechanism includes two clamping mechanisms symmetrically arranged at the end of the inner tube 4, and the clamping mechanism includes a screw rod 5 and an arc-shaped claw 8 th...

Embodiment 3

[0059] Embodiment 3: as figure 1 As shown, a cable sheath protection device in the electric power construction process includes a housing 1, the upper end of the housing 1 is provided with at least one rolling mechanism, and the housing 1 is provided with a rotating shaft 6 axial to the rolling mechanism. Perpendicular to the through hole 12, the bearing 3 is arranged in the said through hole 12, the inner tube 4 is sleeved in the bearing 3, the two ends of the inner tube 4 protrude from the through hole, and the two ends of the inner tube 4 are provided with Wire adjustment fixing mechanism.

[0060] The rolling mechanism includes a groove 9 arranged on the upper end of the housing and a rotating shaft 6 , the rotating shaft 6 is located on the upper part of the groove 9 so that a part of the roller 2 sleeved on the rotating shaft is located outside the groove 9 .

[0061] A bearing 3 is inlaid in the through hole 12 , and the bearing 3 is sleeved on the inner tube 4 so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com