Load type chiral catalyst and preparation method thereof

A chiral catalyst, supported technology, applied in organic chemistry methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalytic activity, poor stereoselectivity, difficult to control, etc., to achieve high catalytic activity, The effect of improving activity and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of nano-silica:

[0016] Add 20 mL of deionized water and 23 mL of ethanol to a 250 mL two-neck round bottom flask, dilute 10 mL of ammonia water with a mass concentration of 25% to 50 mL with deionized water, add it to the flask, and add 77 mL of ethanol and 7.2 mL of a mixture of tetraethyl orthosilicate (TEOS) (ultrasonic for 30 minutes with an ultrasonic instrument), was added dropwise, stirred at room temperature for 3 hours, centrifuged, washed with ethanol for 3 times, and dried in a vacuum oven to obtain Nano silicon dioxide, its diameter is about 250 nm, its scanning electron microscope picture is shown in Figure 4 ;

[0017] Preparation of nano silica with surface grafted chain transfer agent:

[0018] Add 8 g of spherical nano-silica and 250 mL of anhydrous toluene to the reaction flask, install a water separator and reflux until the anhydrous phase of the distillate is separated, remove the water separator after cooling to room temperature, an...

Embodiment 2

[0028] Preparation of nano-silica:

[0029] Add 20 mL of deionized water and 23 mL of ethanol to a 250 mL two-necked round-bottom flask, dilute 10 mL of ammonia water with a mass concentration of 25% to 50 mL with deionized water, add it to the flask, and add 77 mL of ethanol and 9 mL of a mixture of tetraethyl orthosilicate (TEOS) (sonication for 30 minutes with an ultrasonic instrument), the dropwise addition was completed, the reaction was stirred at room temperature for 3 hours, centrifuged, washed with ethanol for 3 times, and dried in a vacuum oven to obtain nano silica;

[0030] Preparation of nano silica with surface grafted chain transfer agent:

[0031] Add 8 g of spherical nano-silica and 250 mL of anhydrous toluene to the reaction flask, install a water separator and reflux until the anhydrous phase of the distillate is separated, remove the water separator after cooling to room temperature, and add 8 g of chain transfer agent S -Methoxycarbonylbenzyl S′-trimetho...

Embodiment 3

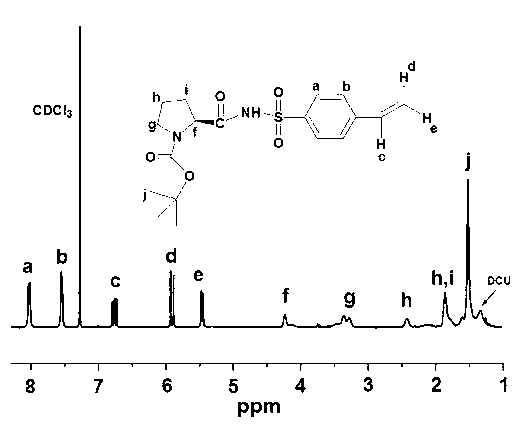

[0039] Add the hair-like nano-silica II prepared in Example 1, 0.1 mmol p-nitrobenzaldehyde, 1 mL acetone and 2 mL DMF in the test tube, react at room temperature for 48 hours, and form a thin layer Chromatography followed the reaction to the end point, after the reaction was completed, centrifuged, the supernatant was extracted three times with ethyl acetate (3 × 10mL), the organic phases were combined, concentrated, and separated by column chromatography to obtain a pure addition product (petroleum ether: acetic acid Ethyl ester=4:1), weighing and calculating yield, hydrogen nuclear magnetic resonance spectrum confirms the target product, separates chiral substance by AD-H chiral column, high performance liquid chromatography (HPLC) records yield to be 82%, e.e. The value is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com