Multi-stage filtering split type air filter and working method thereof

An air filter and filter technology, applied in the direction of separation methods, chemical instruments and methods, and dispersed particle filtration, can solve the problems of reducing the filtering effect of the core layer, reducing the service life, reducing air quality, etc., and achieving increased cleaning Effect, increase adsorption efficiency, increase the effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

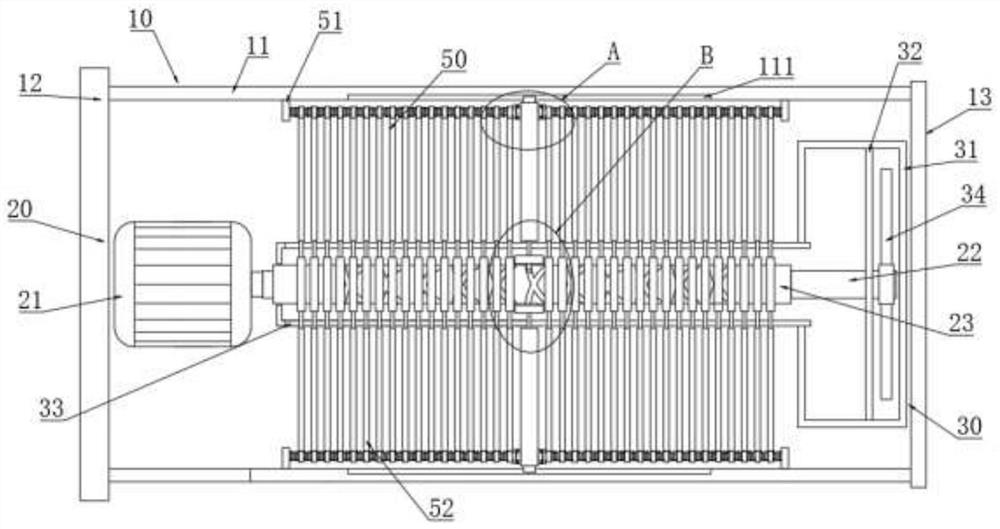

[0054] refer to Figures 1 to 5 , the working method of the multi-stage filter split type air filter of the present embodiment comprises the following steps,

[0055] S1. After the filter body 10 is successfully installed, start the deceleration motor 21, and the deceleration motor 21 works to release heat to heat the inflowing air;

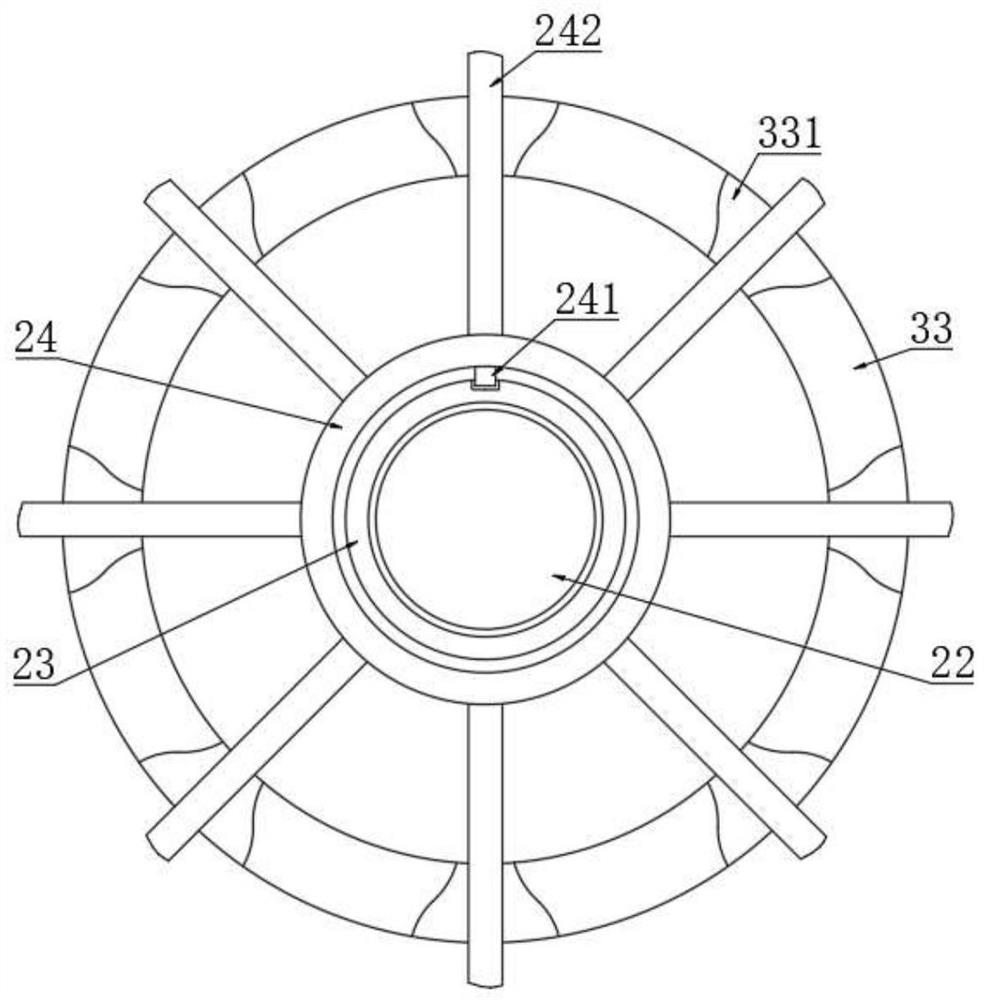

[0056] S2. The deceleration motor 21 drives the motor output shaft 22 to rotate, and the motor output shaft 22 drives the cylindrical cam 23 and the fan blade 34 to rotate. When the fan blade 34 rotates, an air inlet 12 is formed inside the filter body 10 to point to recovery air flow inside the vertical end 31 of the shell;

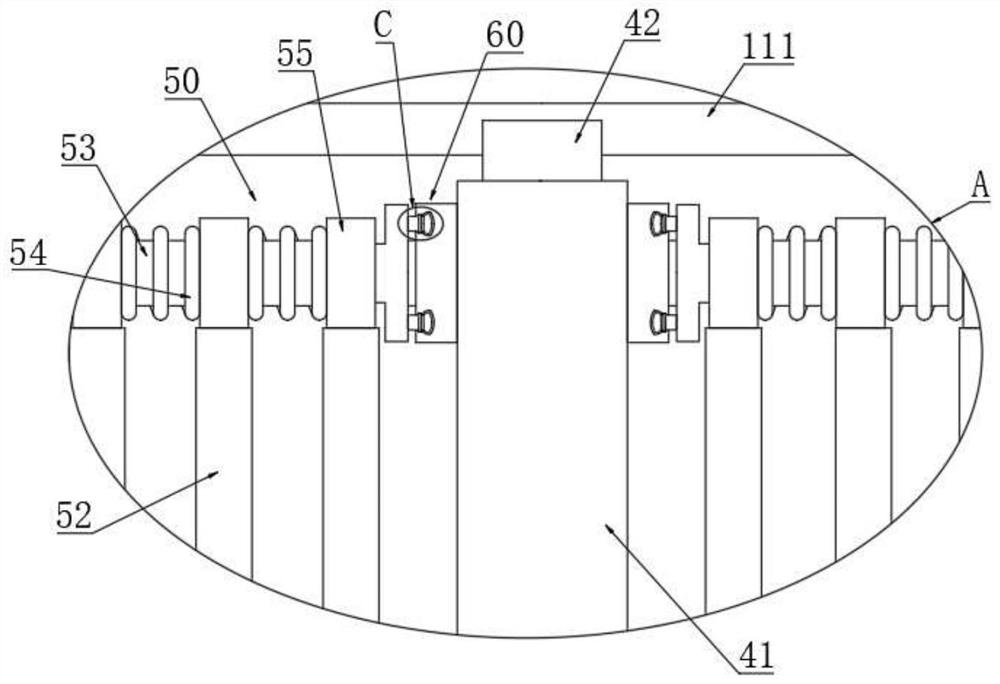

[0057] S3. The cylindrical cam 23 drives the pressure applying plate 41 to reciprocate along the length direction of the inner cavity of the filter housing 11, and continuously applies pressure to the filter element assemblies 50 located on both sides:

[0058] S4, the dust attached to the surface of the filter core layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com