Touch screen film covering equipment

A technology of touch screen and film covering, applied in the direction of external support, static electricity, electrical components, etc., can solve the problems of affecting the quality of film covering, the lack of elimination function of touch screen, and the waste debris on the film surface is easy to adhere to the film, so as to increase the convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

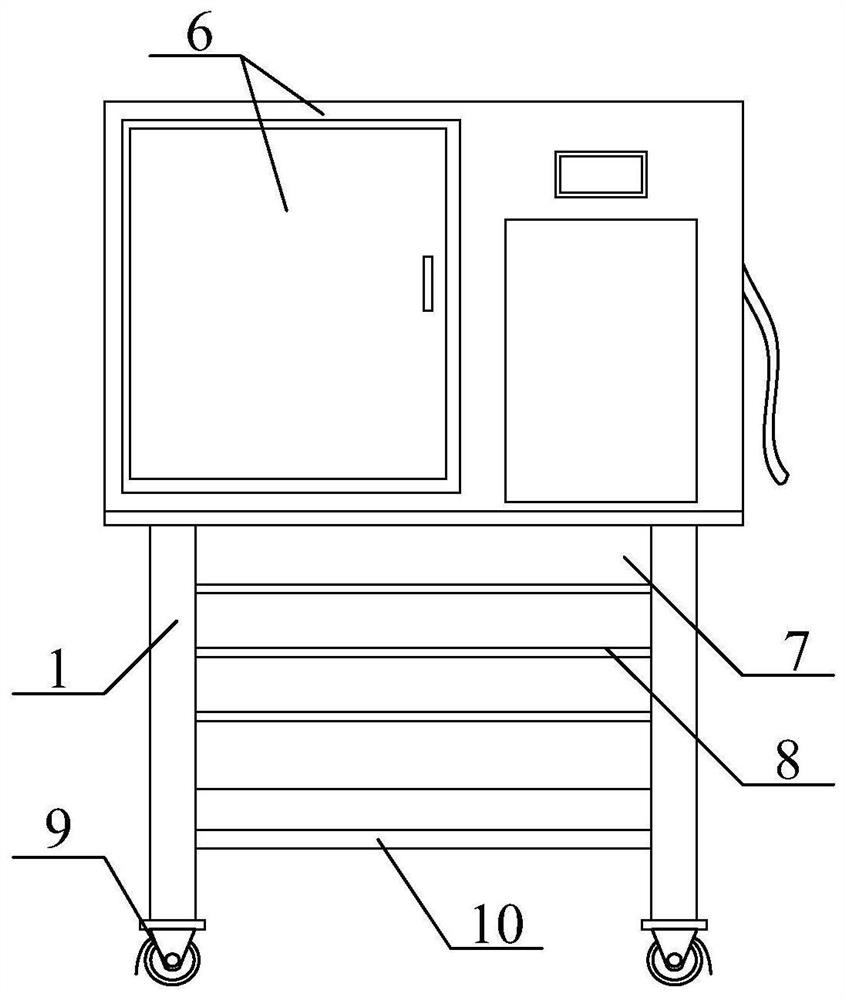

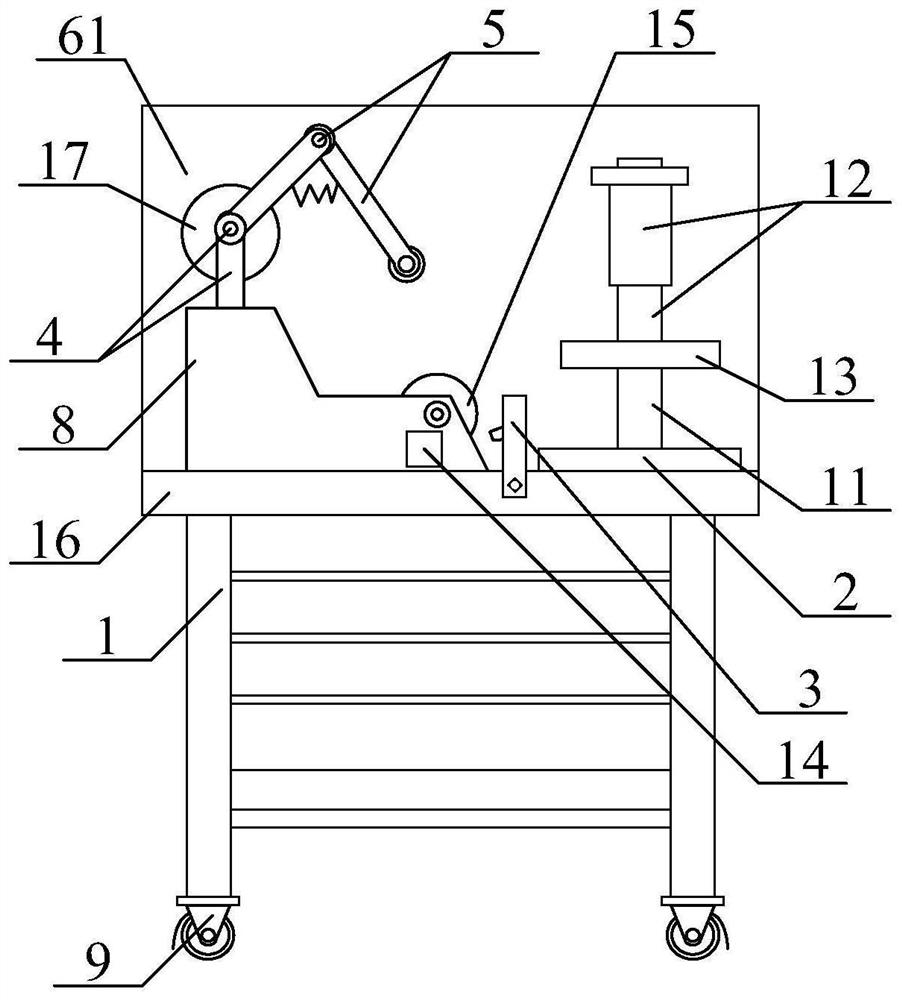

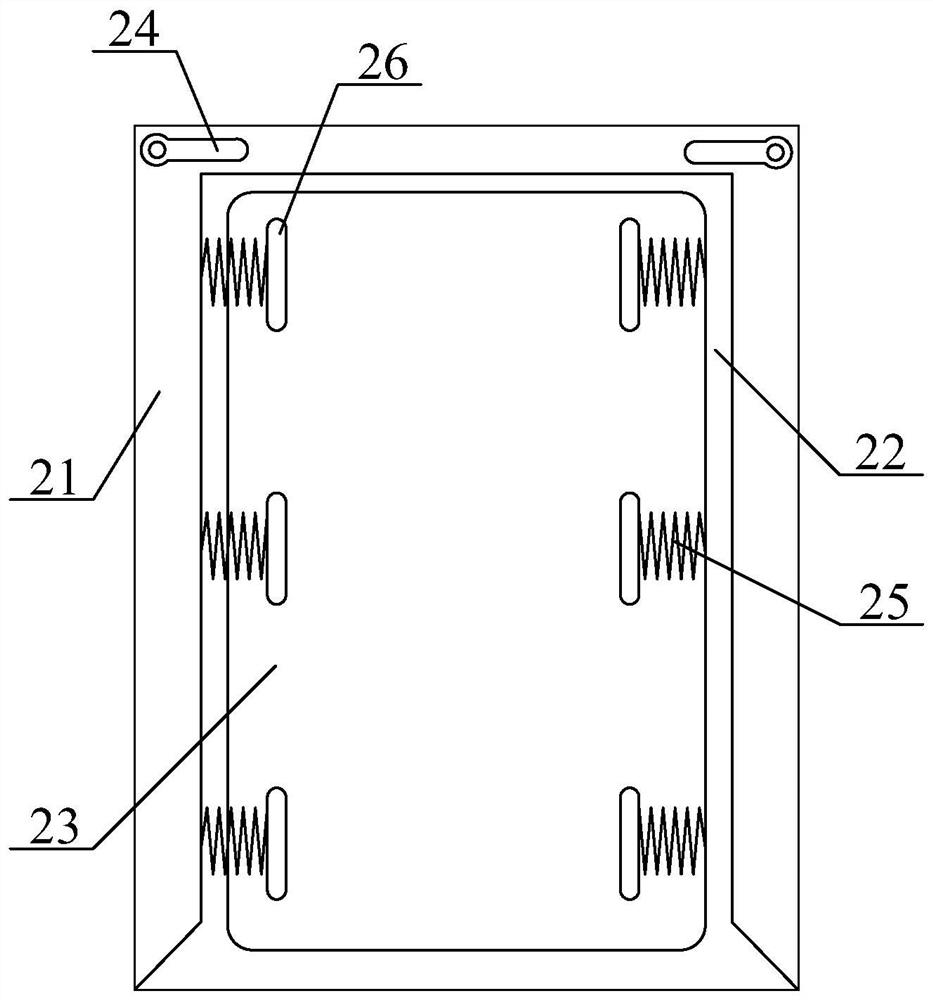

[0048] as attached figure 1 to attach figure 2 As shown, the present invention provides a touch screen laminating device, including a support leg 1, a touch screen deck assembly 2 with a protective function, a cutter assembly 3 that can be connected to a trachea, an adjustable roll film support assembly 4, a roll film pressure Rod assembly 5, protective box assembly 6 for convenient loading and unloading, lower housing cabinet 7, partition plate 8, moving wheel 9, shaping bar 10, support column 11, lamination press 12, touch screen lamination mold seat 13, steel Roller driving motor 14, conveying steel roller 15 and processing operation platform 16,

[0049] The touch screen deck assembly 2 with protection function is screwed on the upper right side of the processing operation platform 16; the cutter assembly 3 which can be connected to the air pipe is screwed on the upper middle position of the processing operation platform 16; The adjustable film support assembly 4 is scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com