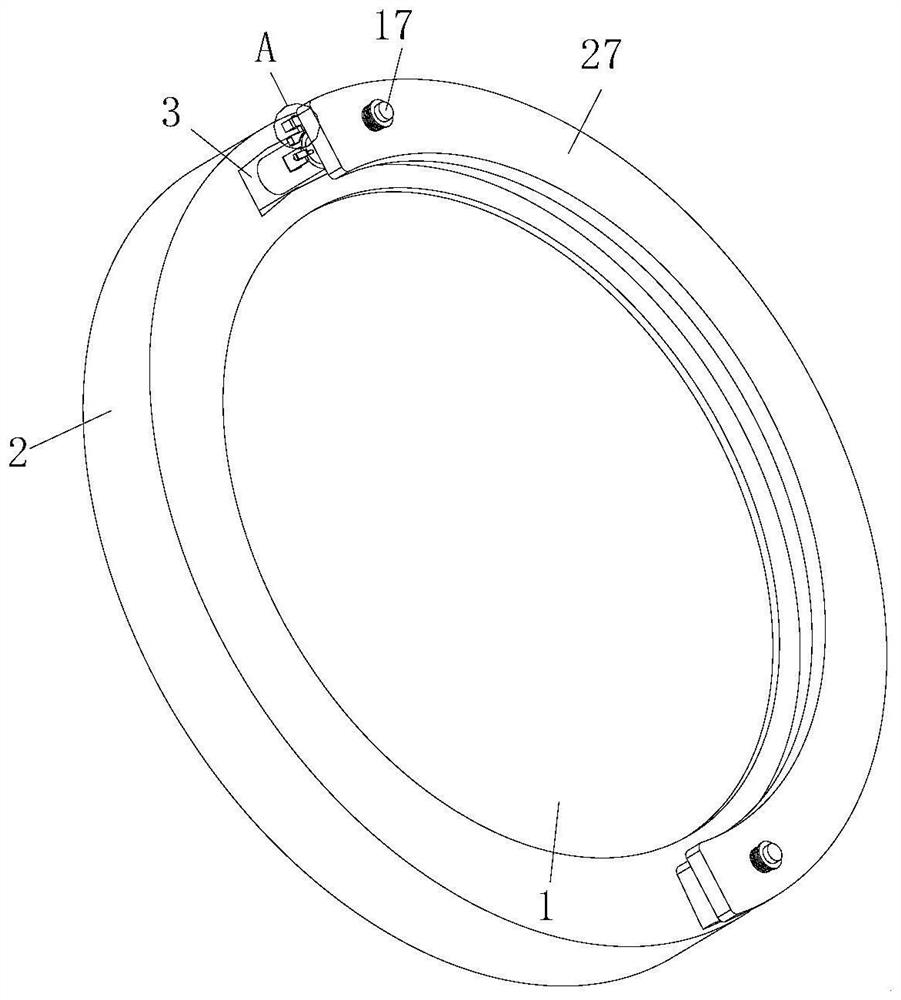

Optical glass cleaning device

A technology for optical glass and cleaning devices, which is applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as affecting the use of multiplexers and being stained with dust, and achieve the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

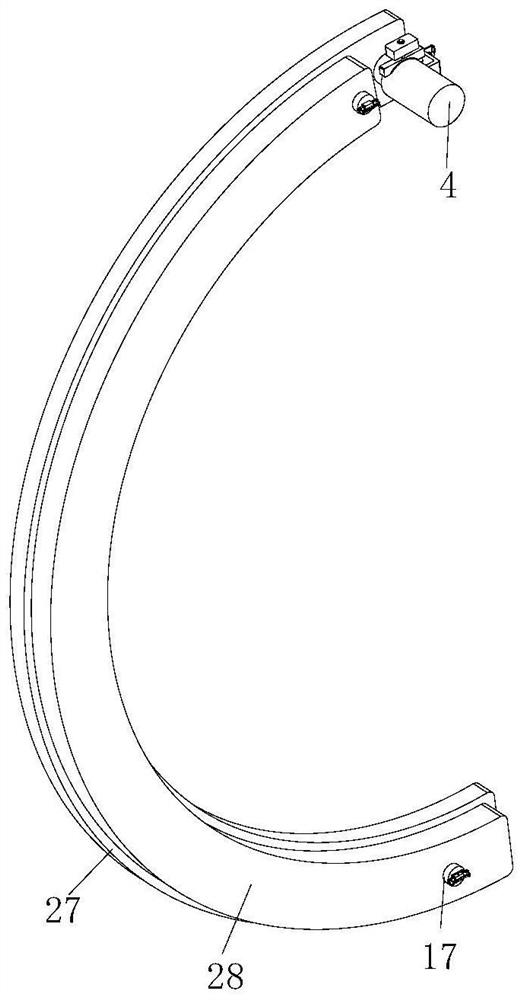

Method used

Image

Examples

Embodiment approach

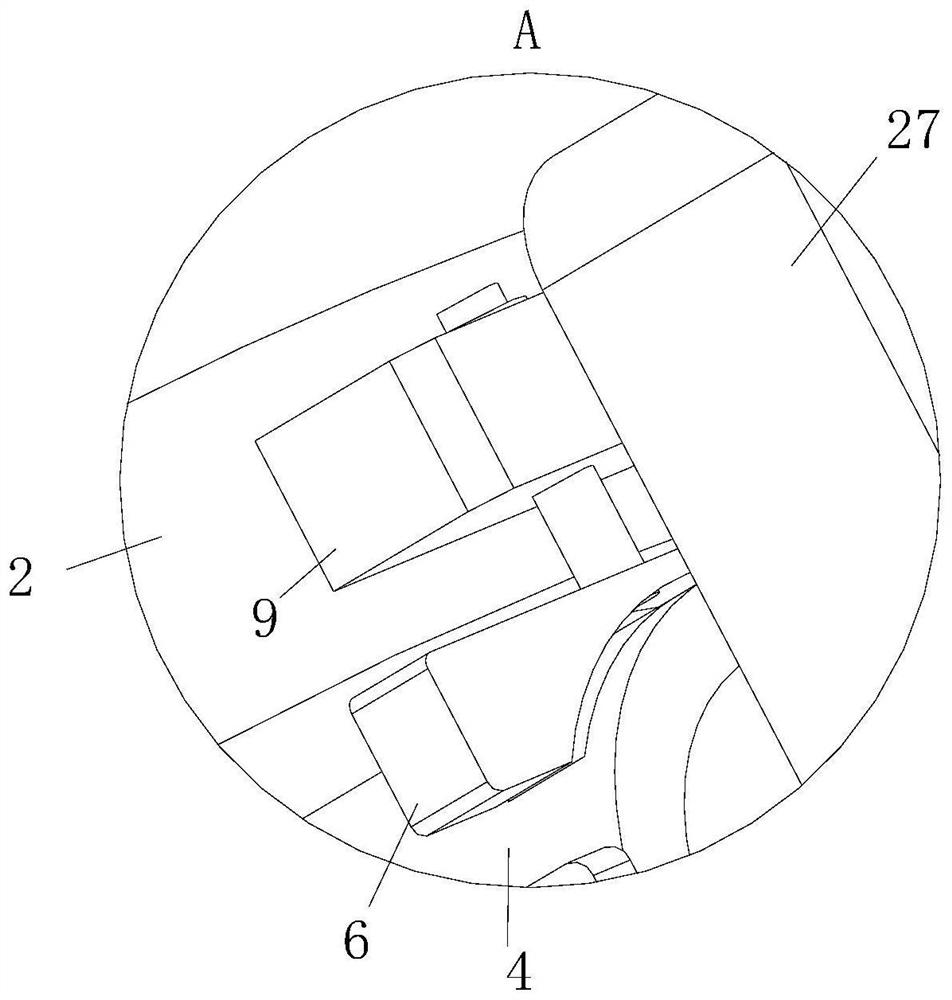

[0030] As an embodiment of the present invention, a fixed block 9 is fixedly connected to the side of the fixed ring 2 close to the rectangular groove 3, and an insertion rod 8 is slidably connected to the inside of the fixed block 9, and the insertion rod 8 is close to the sliding post. One end of 4 is fixedly connected to the limit block 6, and the side of the limit block 6 close to the sliding column 4 is arc-shaped; during work, by pulling the insertion rod 8, the insertion rod 8 drives the limit block 6 to slide, so that The limit block 6 is no longer in contact with the sliding column 4, then let the sliding column 4 slide in the rectangular groove 3, and then slide the sliding column 4 back to its original position, at this time, push the insertion rod 8, so that the insertion rod 8 pushes the limit block 6. At this time, the limiting block 6 will block the sliding column 4, which plays a role of limiting the sliding column 4.

[0031] As an embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com