Vapour-liquid distribution device

A distribution device and downflow technology, which is applied in the field of liquid-gas distribution device, can solve problems such as uneven liquid distribution and achieve good wetting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

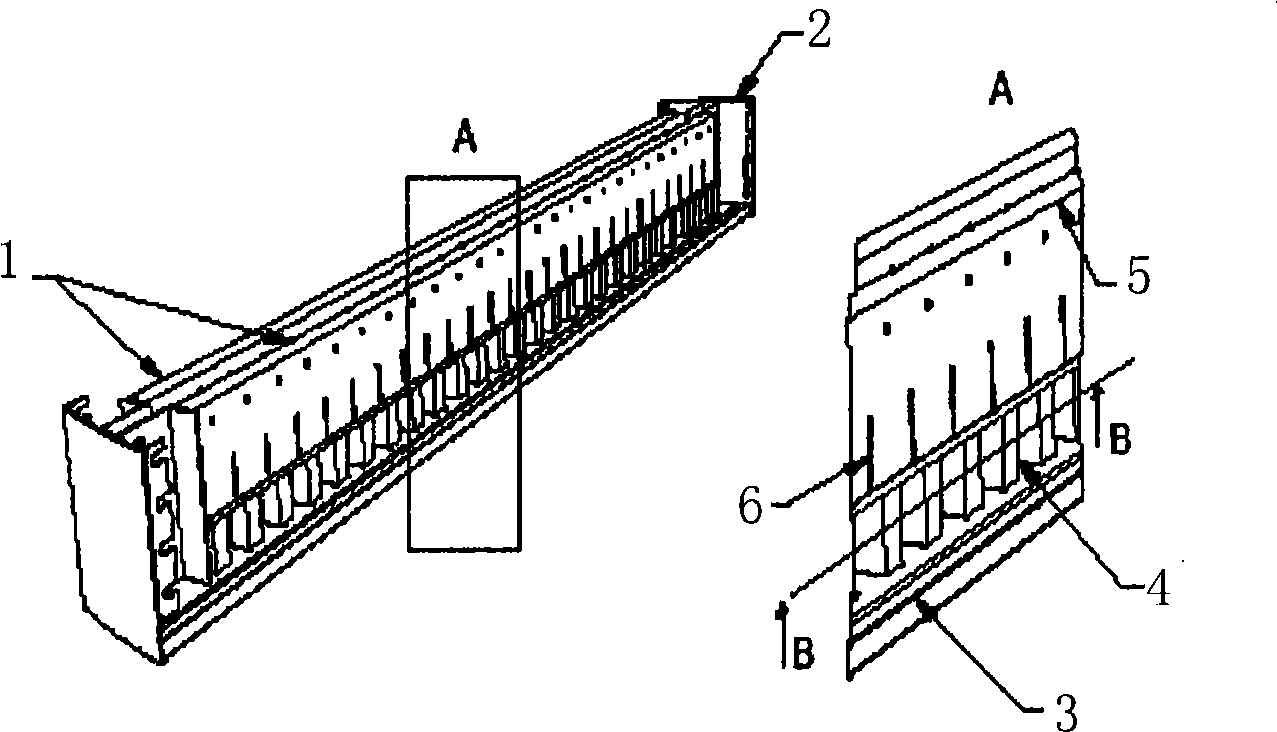

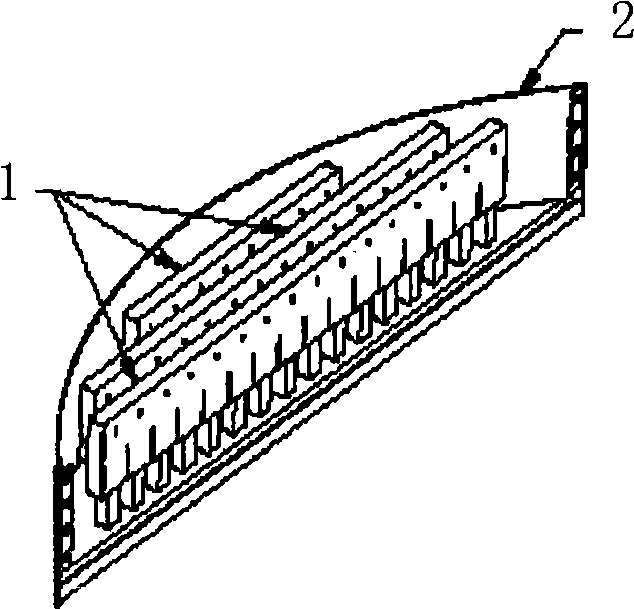

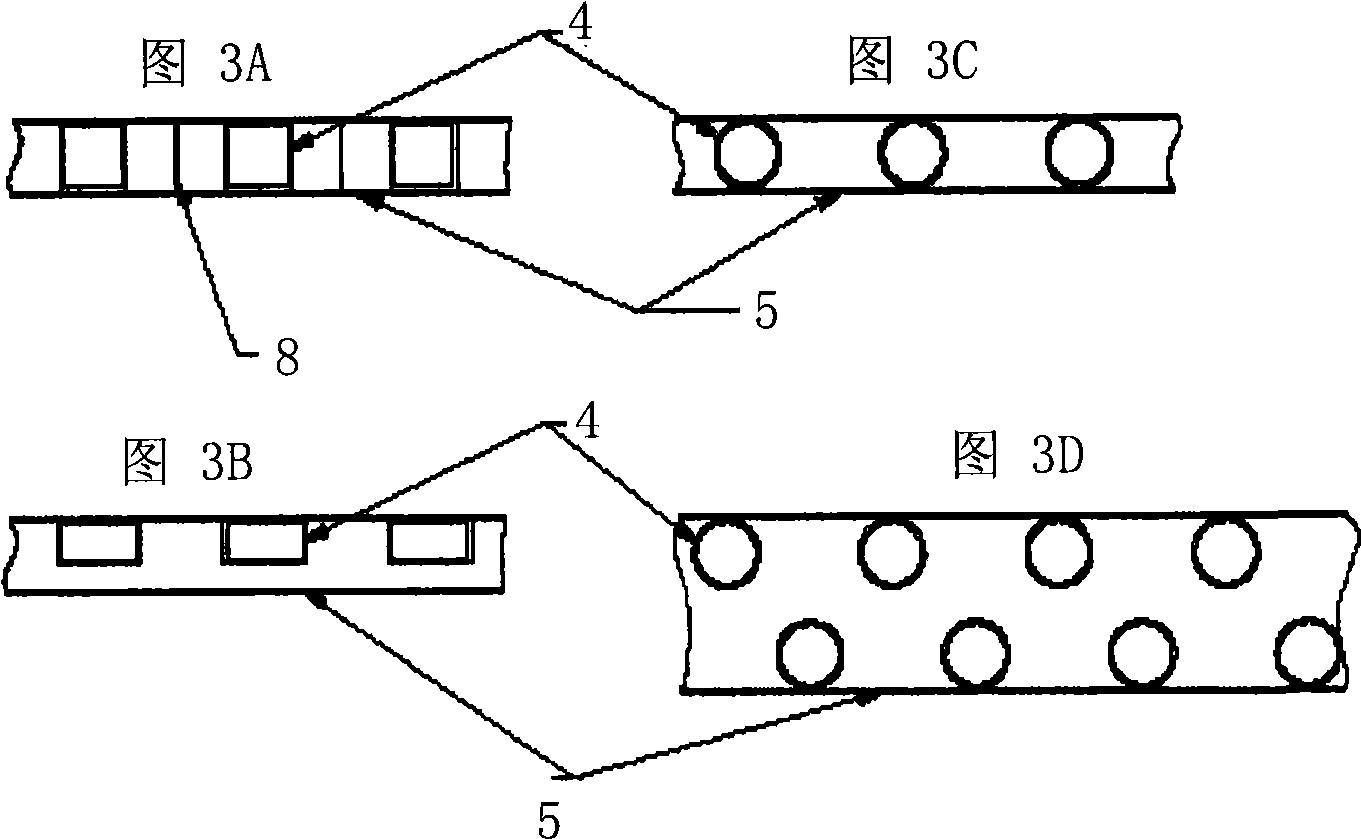

[0030] exist figure 1 and figure 2 The concept of a liquid-gas distribution design (called a self-supporting structure) is represented in . The device comprises one or several BOXVLTs extending from one side of the reactor inner wall to the other side of the reactor inner wall, with skirts 2 curved at a curvature corresponding to the curvature of the reactor inner wall (not shown) so as to be airtight Install. The long sides 7 of the self-supporting structure are linear and fit together with either another self-supporting structure (not shown) or a non-self-supporting tray plate equipped with one or several BOXVLTs (not shown). All connections are essentially leak-free. Each BOXVLT includes a common riser cap that covers 2 or more downcomers 4 . The downcomer 4 can vary in size, shape and pattern of arrangement (see image 3 example of). Each downcomer fits into a hole drilled in the base plate 3 . One or more vertical narrow slots 6 are cut in the side walls of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com