Roadway-mining face collaborative water injection structure for dust fall of coal mine and use method thereof

A technology for dust reduction and roadway, which is applied in dust prevention, mining equipment, earthwork drilling and mining, etc., can solve the problems of low wetting efficiency and poor hydrophilicity of coal, so as to improve water injection efficiency, reduce dust production in mining face, Effect of suppressing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

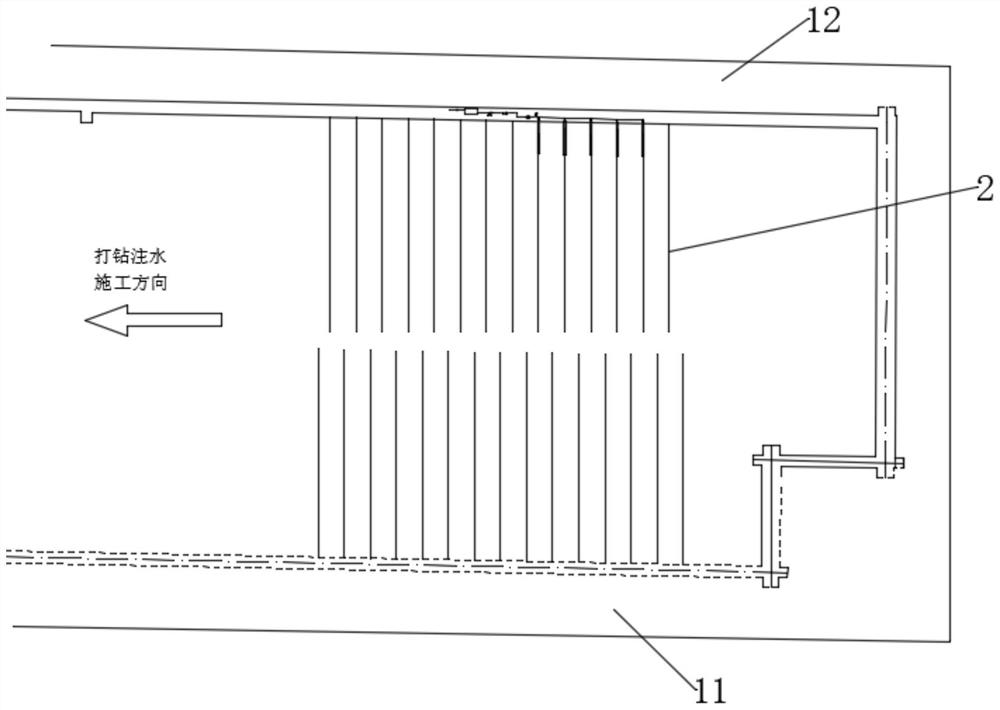

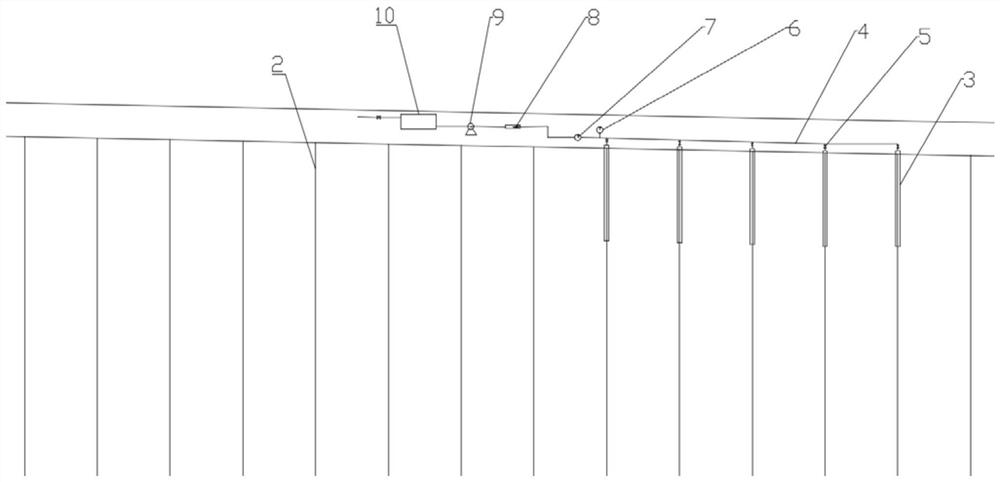

[0040] Drill holes in the roadway and mining face, adjust the hole depth and inclination angle according to the site conditions, and bury the water injection pipe. For the sealing treatment of the water injection hole, the MZF-Ⅱ type hole sealer is used, and the special bag hole sealer (FKJW-50 / 0.6) is about 12m long, and the air injection is used. The slurry pump is used to inject grout into the hole sealer, using FKL-1 type hole sealing grout, the water-cement ratio is 1:1, after the two bladders are filled, disconnect the blast valve in the middle of the hole sealer hose to realize 1. The whole process of grouting in the 9m section of the hole is blocked, and after 24 hours of solidification, network water injection is carried out. Install cut-off valve 5, pressure gauge 6, flow meter 7, one-way valve 8, booster pump 9, water tank 10 on the main water injection road, use repeated, cyclic, and multi-round methods to inject water, adjust the water injection volume of the bore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com