Preparation method of high-interface-strength fiber composite material

A fiber composite material and interface strength technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of reducing fiber strength, difficult to control modification, and high equipment requirements, to increase interface strength, improve wetting efficiency, and improve The effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and embodiments.

[0017] A method for preparing a fiber composite material with high interface strength, including impregnation, electric field assisted infiltration and high temperature curing;

[0018] Impregnating material: first put the liquid resin 1 into the resin tank; the fiber 2 enters the resin tank to soak the liquid resin 1, and after the liquid resin 1 showers, the fiber 2 and the liquid resin are fully infiltrated;

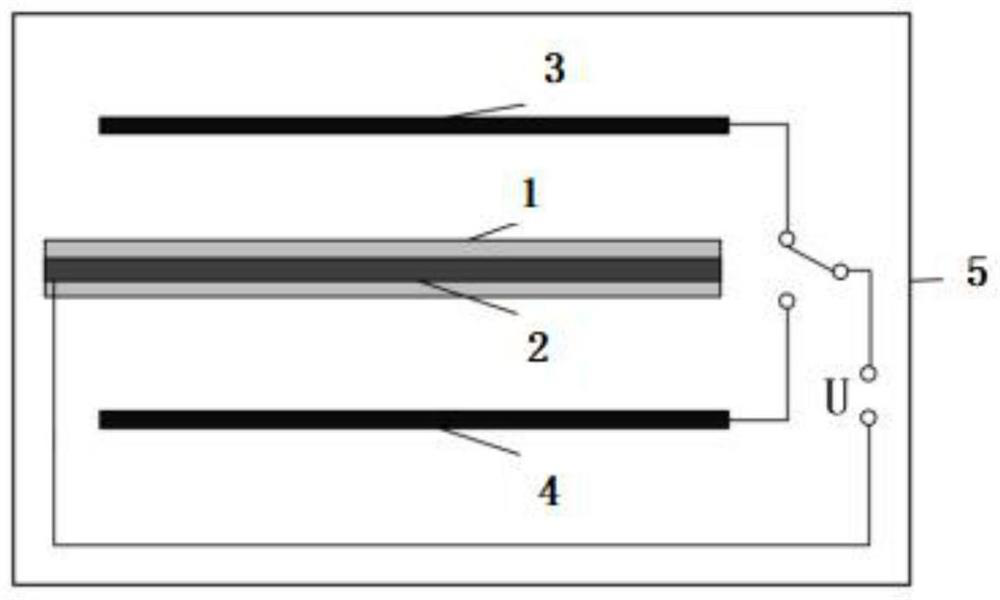

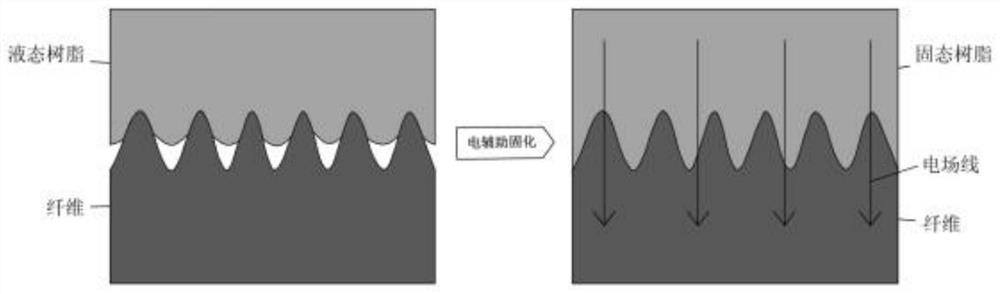

[0019] Electric field assisted infiltration and high-temperature curing: the fiber 2 soaked in the liquid resin 1 shower passes through the high-temperature electric field box 5 (50-300°C) with an electric field, such as figure 1 As shown, the high-temperature electric field box 5 includes a first electrode 3 and a second electrode 4 connected by an electric field U (1-100KV / cm); the electric field U drives the liquid resin 1 to flow, so that the liquid res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com