Rapid cellulose wetting equipment and rapid cellulose wetting process

A cellulose, fast technology, applied in the direction of mixer, mixing method, mixed material pretreatment, etc., can solve the problems of non-continuous production, affecting quality, long stirring time, etc., to reduce organic solvent consumption, reduce solvent consumption, reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

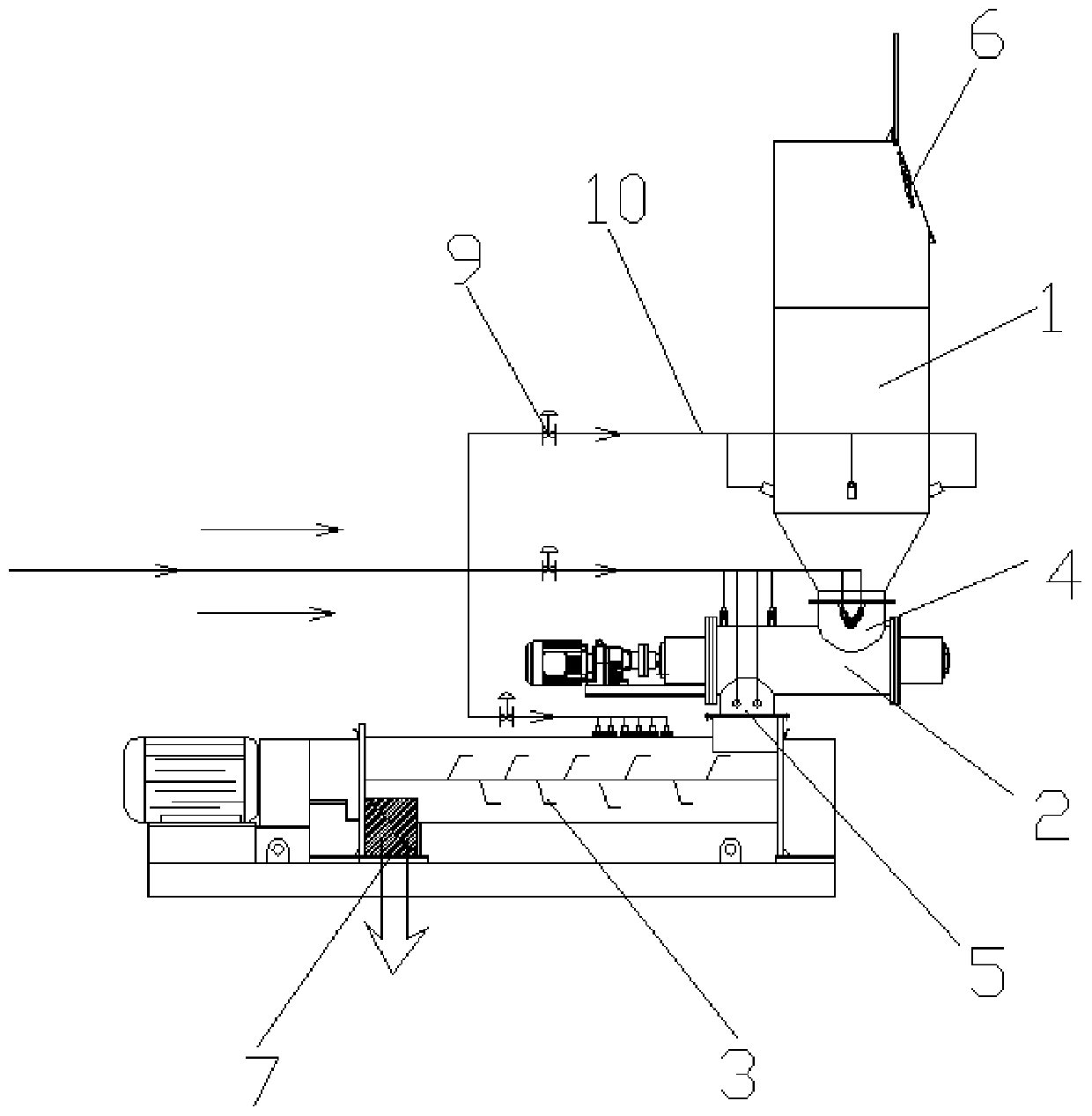

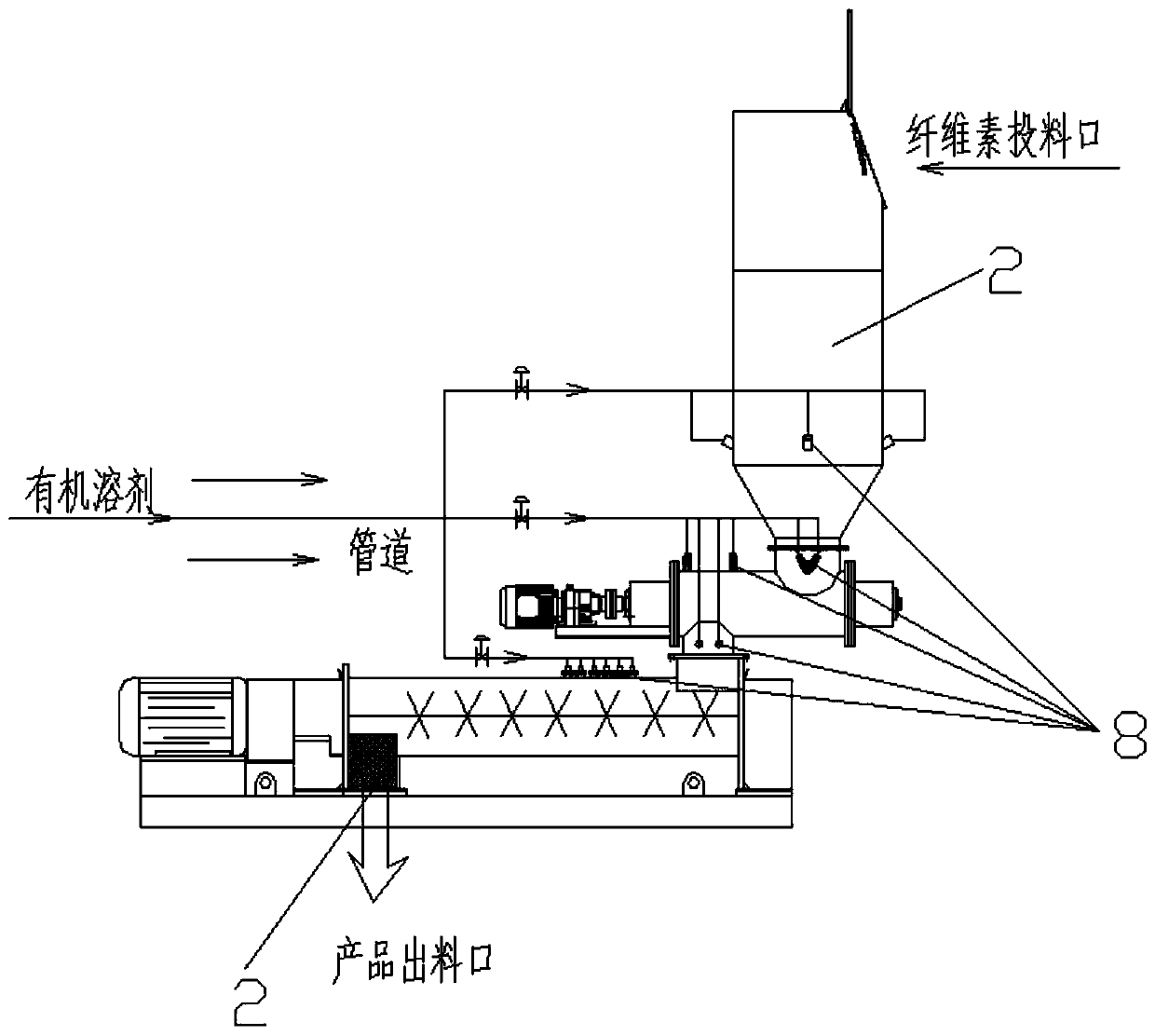

[0029] refer to Figure 1 to Figure 2 A cellulose rapid wetting equipment shown includes a silo 1, a premixer 2, a high-speed continuous mixer 3, cellulose, an organic solvent, a pipeline and a control system, and the silo 1 is set at the upper end of the premixer 2 , between the silo 1 and the premixer 2 is provided with a pipeline-4 and connected by the pipeline-4, the high-speed continuous mixer 3 is arranged at the lower end of the premixer 2, the high-speed continuous mixer 3 and the premixer 2 Be provided with pipeline two 5 between and be connected by pipeline two 5, the upper end of described feed bin 1 is provided with cellulose feed opening 6, the lower end of high-speed continuous mixer 3 is provided with product discharge port 7, described feed bin 1, The premixer 2, the high-speed continuous mixer 3, the pipeline one 4, and the pipeline two 5 are provided with a plurality of solvent inlets, and a nozzle 8 is installed on the solvent inlet, and one end of the nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com