Printing and dyeing pre-wetting device

A technology of pre-wetting and extrusion device, applied in textile and paper making, vibration treatment, liquid/gas/vapor removal with extrusion rollers, etc., can solve problems such as affecting production efficiency, affecting product quality, and uneven pre-wetting, etc. Achieve short pre-wetting time, improve wetting efficiency and reduce processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

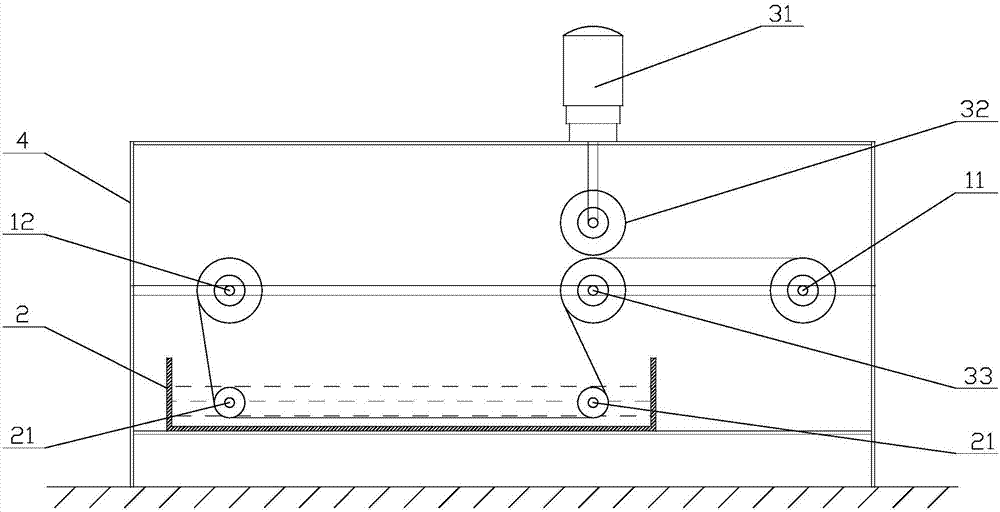

[0012] The present invention as figure 1 As shown, a printing and dyeing pre-wetting device includes a pair of cloth guide rollers, an extrusion device and a pre-wet tank, and a pair of said cloth guide rollers are divided into active cloth guide rollers 11 and driven cloth guide rollers 12, which are respectively fixed on The two ends of the bracket 4, the active cloth guide roller 11 is driven by a motor, the extruding device and the pre-wet tank 2 are respectively fixed on the bracket 4, and the bottom of the pre-wet tank 2 is provided with an ultrasonic oscillator and heating device, a pair of squeeze rollers placed above the pre-wet tank 2. The cloth to be processed is wound on the driven cloth guide roller 12, passes through the pre-wet tank 2, and is pre-wetted. Under the guidance of the guide roller 21 in the pre-wet tank 2, it passes through the extrusion device to squeeze excess water, and then Pre-wetting is done by winding on the drive roll. Make the pre-wetting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com