Coal gangue crushing and dust collection device

A dust removal device and coal gangue technology, applied in the direction of grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of uneven particle size, air pollution, environmental pollution, etc., achieve sufficient and thorough crushing, and increase the contact area , The effect of fast crushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

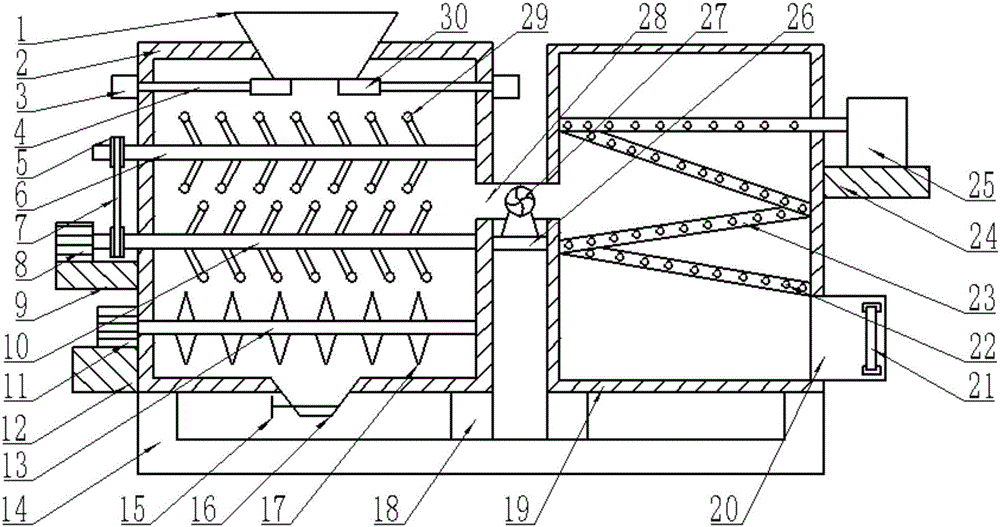

[0018] see Figure 1-2 , the present embodiment provides a coal gangue crushing and dedusting device, comprising a crushing box 2, a base 14 and a dust removal box 19; the crushing box 2 is provided with a feed hopper 1, a cylinder 3, a first drive motor 8, a first placement Plate 9, the second drive motor 11, the second placement plate 12 and the discharge port 16; the feed hopper 1 is arranged in the middle of the upper end of the crushing box 2; the cylinder 3 is fixed on the left and right ends of the crushing box 2, and the cylinder 3 A telescopic shaft 4 is provided; the telescopic shaft 4 is provided with two, respectively connected to two cylinders 3, the telescopic shaft 4 runs through the crushing box 2, and the inner side is provided with a stopper block 30; the said stopper block 30 is provided with two, The stopper block 30 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com