Desiccant regeneration device

A regeneration device and desiccant technology, applied in filter regeneration, inorganic chemistry, filtration separation, etc., can solve problems such as uneven drying, desiccant drying, precipitation, etc., to achieve improved wetting efficiency, high wetting uniformity, uniform wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

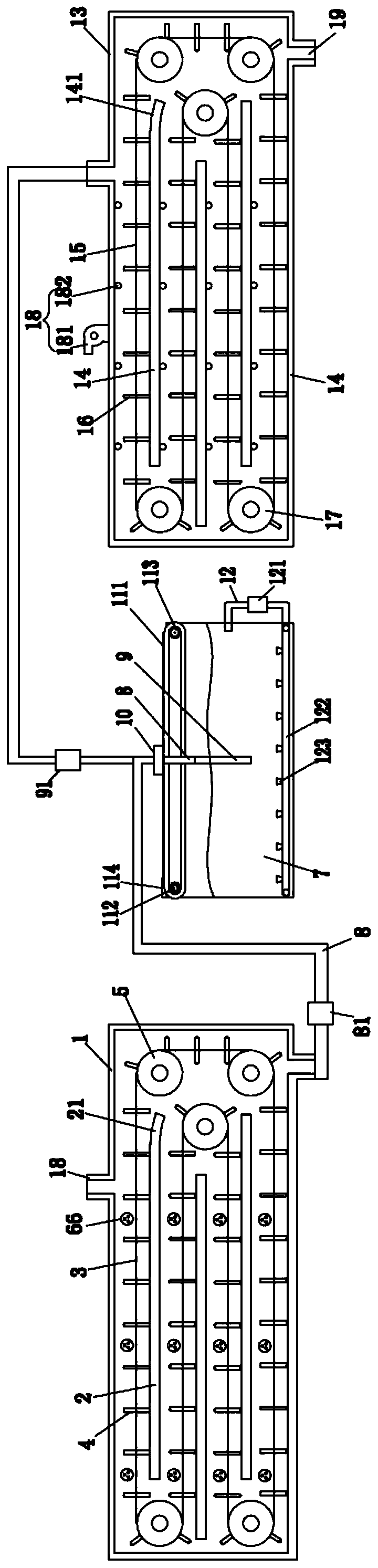

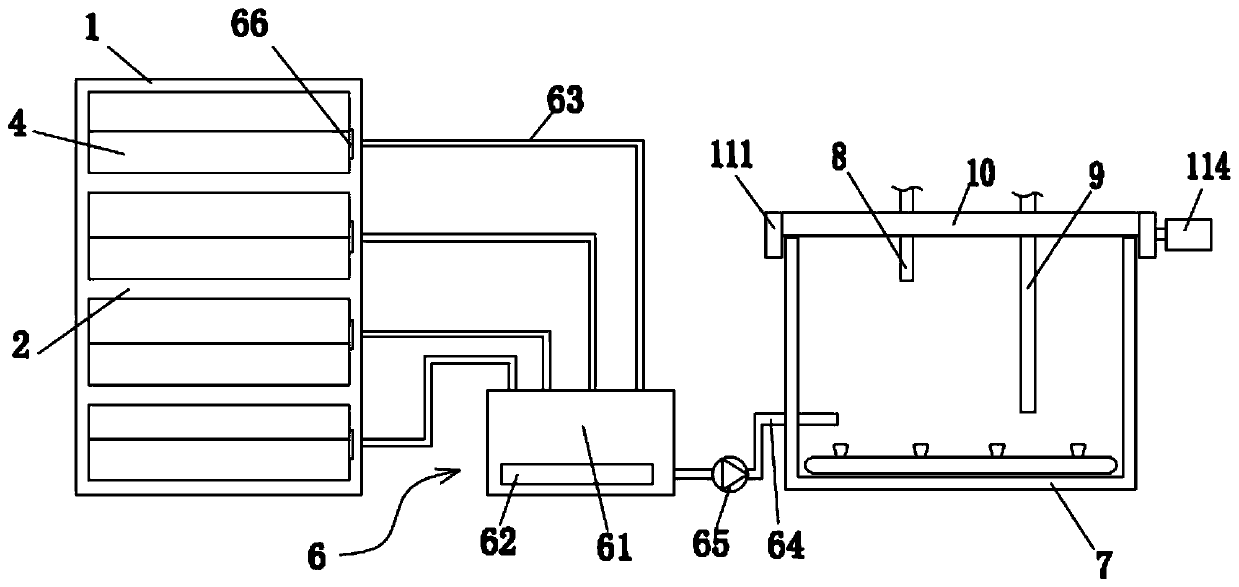

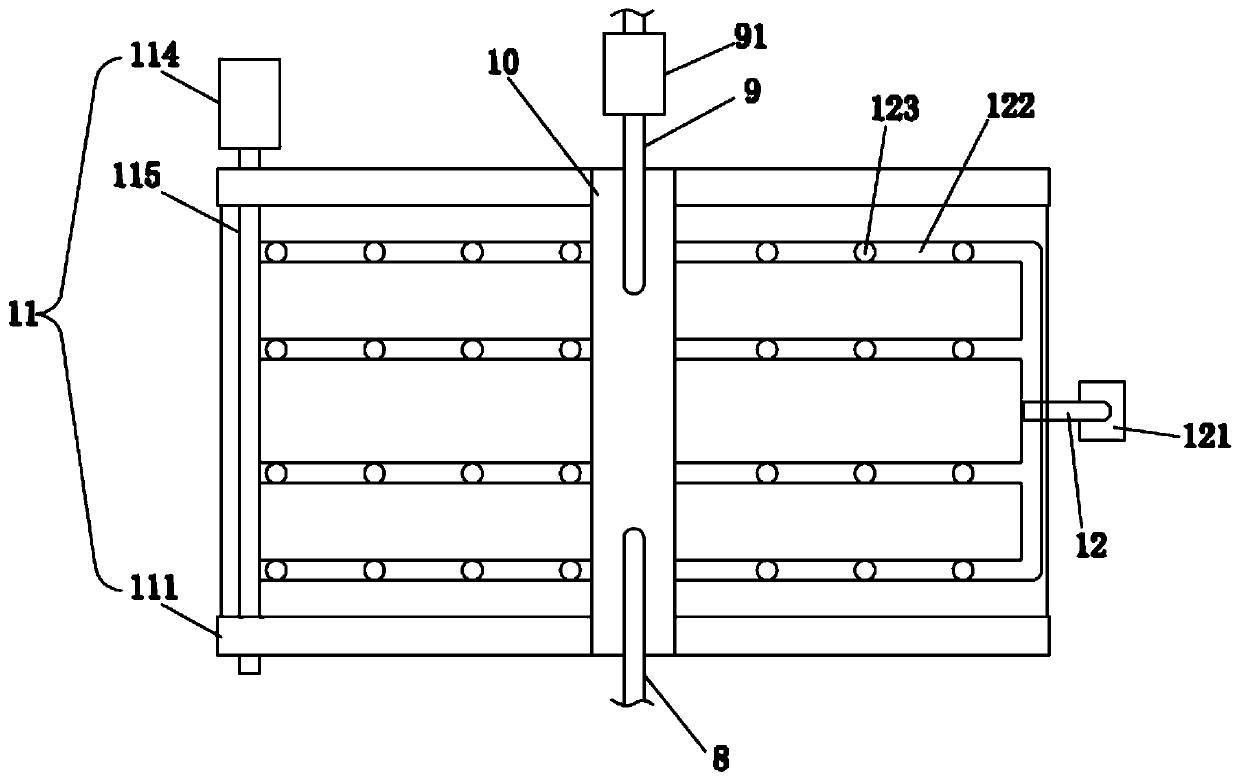

[0036] The specific embodiment of the present invention is as Figure 1 to Figure 4 As shown, a desiccant regeneration device includes a wetting box 1 and a soaking box 7, and also includes a drying box 13. The wetting box 1, the soaking box 7 and the drying box 13 are connected in sequence, and the wetting box 1 is provided with The feed port 18 and the drying box 13 are provided with a discharge port 19 . The inside of the humidifying box 1 is divided into at least two layers of first interlayers arranged one above the other by the first seat plate 2 , and the feeding port 11 is arranged on the topmost first interlayer. Each first compartment is provided with steam vents 66 . Each of the first compartments is connected end to end in turn to form a circular circulation channel. A first circulation conveying device is provided in the circulation passage, and a plurality of first scraper plates 4 arranged at intervals along the conveying path are arranged on the first circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com