Anti-scalding cooking container and steam heating type electric cooker

A cooking container and steam technology, which is applied to the cover of cooking utensils, the steam cooking utensils, the structure of cooking utensils, etc., can solve the problems of thermal deformation of the handle, reduce the installation firmness of the handle, and high temperature of the handle, and achieve the purpose of reducing heat transfer and improving the handle. Anti-scalding effect, the effect of ensuring end-holding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

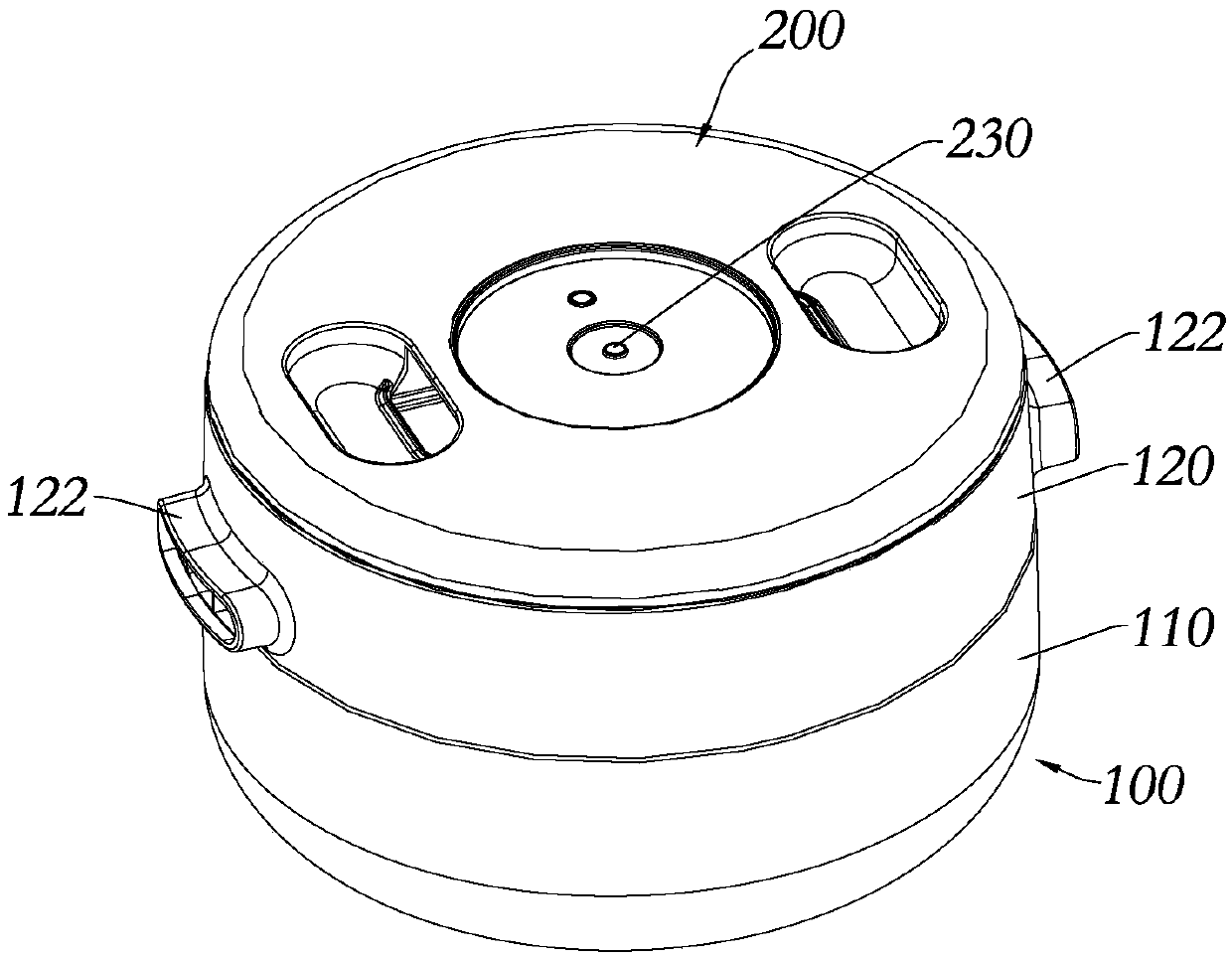

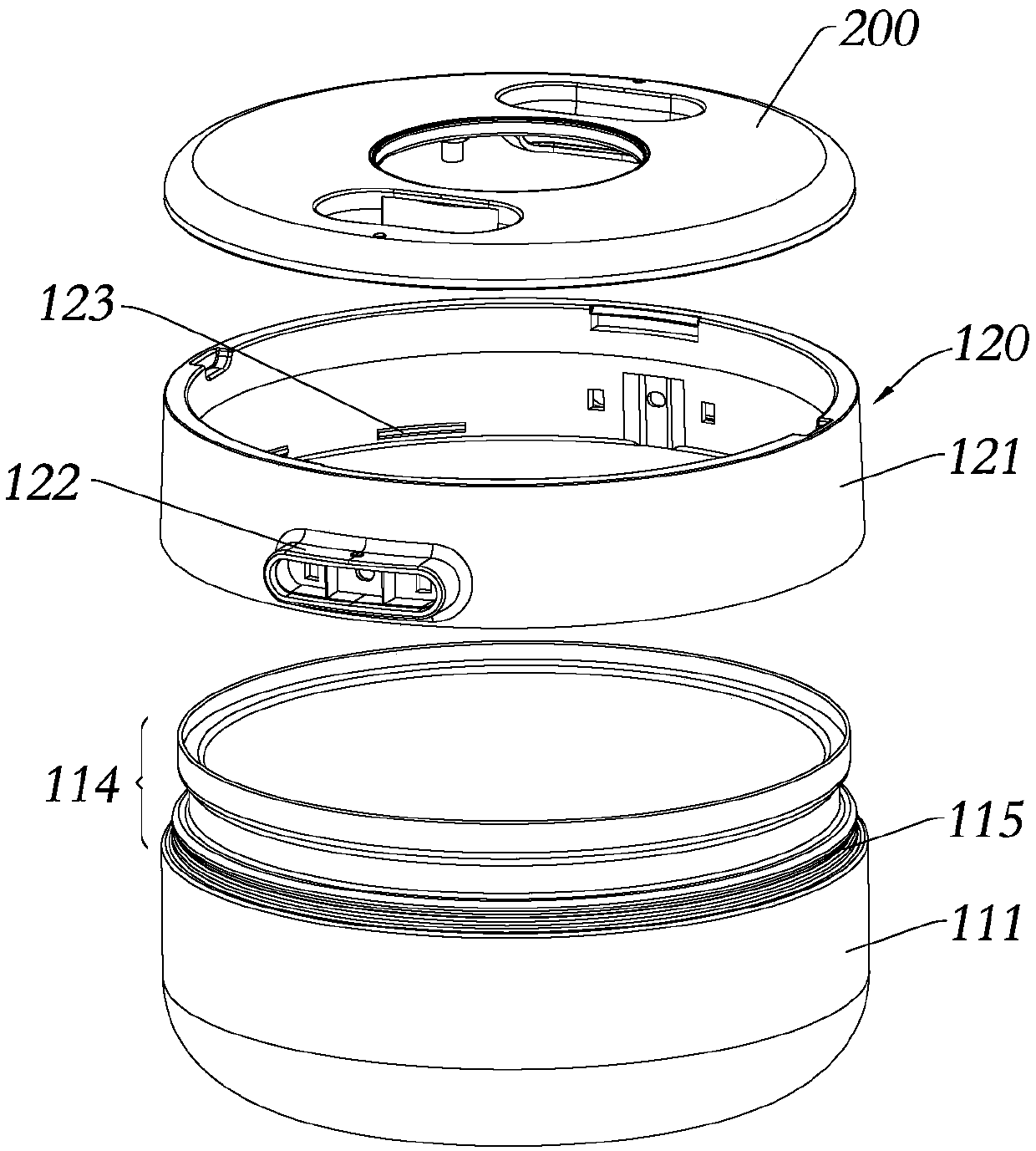

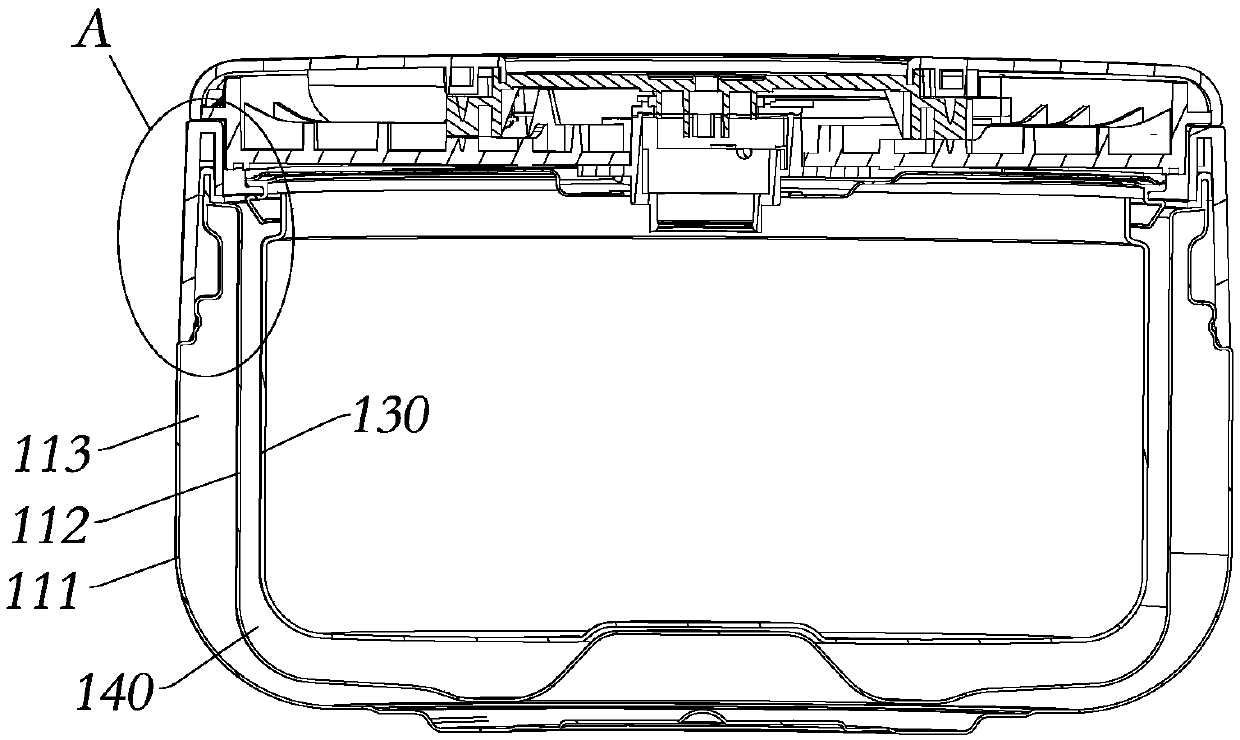

[0051] refer to Figure 1-4 The anti-scalding cooking container proposed in Embodiment 1 of the present invention includes a container body 100 and a cover body 200. The cover body 200 is provided with a steam injection port 230. The cover body 200 is detachably covered on the container body 100 to form a cooking cavity. The container body 100 includes a metal liner 110, a heat insulating ring 120 and an inner pot 130, the metal liner 110 includes an outer liner 111, an inner liner 112 and a connecting portion 116, the mouth of the outer liner 111 and the inner liner 112 The mouth parts are connected by the connecting part 116 to form a closed heat-insulating cavity 113 in the metal bladder 110 , and the heat-insulating cavity 113 can be in a vacuum or semi-vacuum state to improve the heat-insulating effect of the heat-insulating cavity 113 . The inner pot 130 is accommodated in the inner layer body 112 of the metal liner 110 , an interlayer 140 for steam circulation is formed...

Embodiment 2

[0058] refer to Figure 5 , 6 In this embodiment, on the basis of Embodiment 1, the sealing and matching structure between the cover body 200 and the container body 100 is optimized, and the cover body 200 and the heat insulation ring 120 cooperate with each other, so that the cover body 200 is accurately covered on the container body 100, so as to It is ensured that the first sealing ring 300 is reliably attached to the metal liner 110 to realize an effective and reliable seal between the metal liner 110 and the cover body 200 . Specifically: the cover 200 of this embodiment includes an upper cover 210 and an inner cover 220 , the upper cover 210 is made of plastic, the inner cover 220 is installed inside the upper cover 210 , and the first sealing ring 300 is installed around the inner cover 220 . During the closing process, the upper cover 210 and the heat insulating ring 120 cooperate with each other, and the heat insulating ring 120 is used to limit the closing position ...

Embodiment 3

[0063] refer to Figure 8 , the present embodiment proposes a steam-heating electric rice cooker, comprising a pot body 600 and the anti-scalding cooking container described in any of the above embodiments, one side of the pot body 600 extends outwardly from a carrying platform 610, and the cooking container is preferably placed on a carrying table On the table 610, a steam generator is arranged in the cooking pot body 600. When the rice cooker cooks rice or porridge, the high-temperature steam generated by the steam generator passes into the container body through the steam injection port on the cover body. Of course, in addition to the steam-heated rice cooker described in this embodiment, the cooking container described in Embodiment 1 can also be applied to existing steam-heated rice cookers in other forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com