Polychloroethylene antifog non-drop greenhouse film

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of transparent covering materials, can solve the problems of unsatisfactory anti-fog effect, limited promotion and application, and increased cost, so as to be beneficial to photosynthesis, increase light intensity, and improve shed warm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

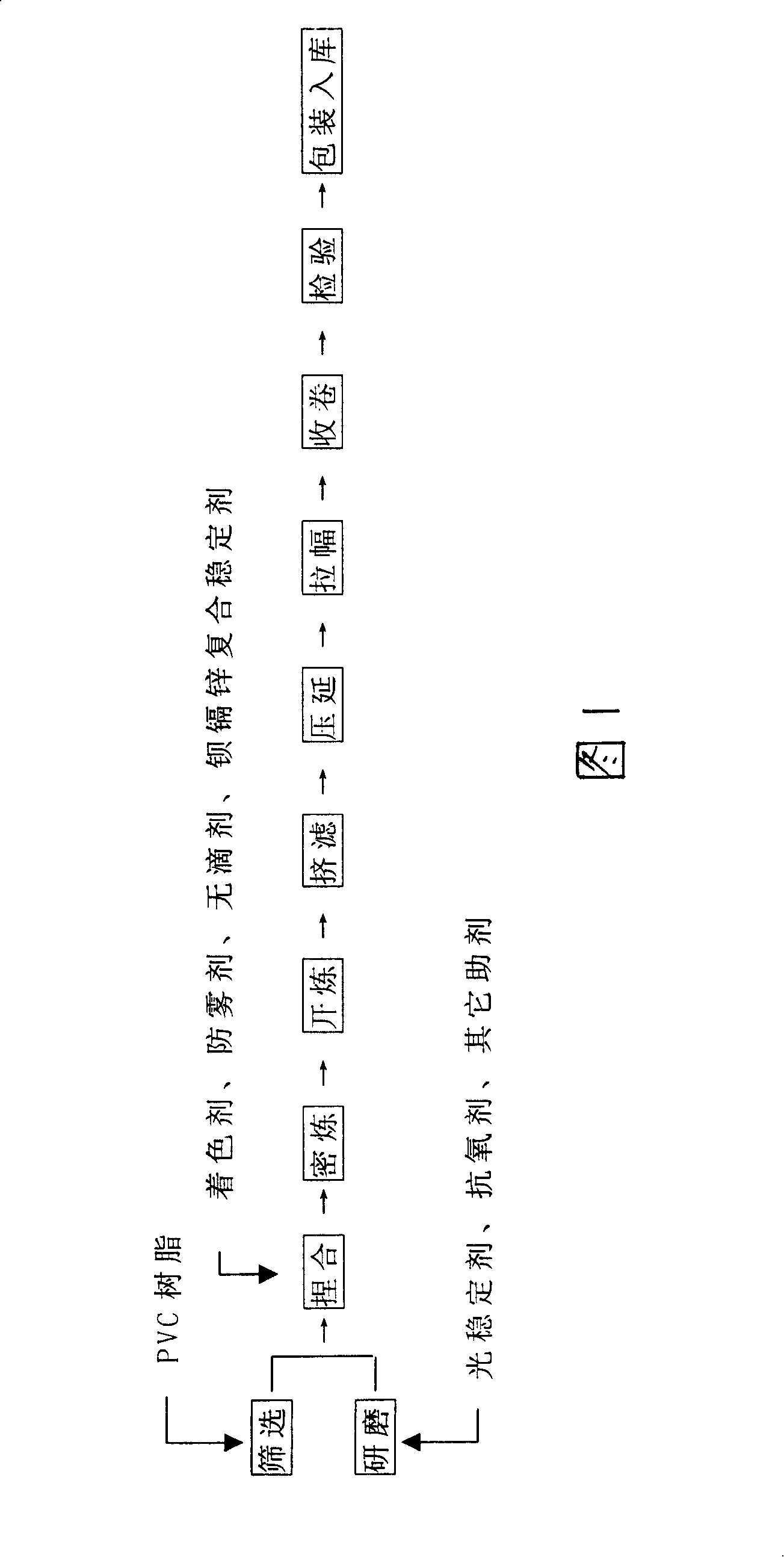

Method used

Image

Examples

Embodiment 1

[0042] Table 1

[0043] raw material name

Raw material weight: kg

pvc

100.00

DOP

42.00

DOA

5.00

3.00

Barium cadmium zinc composite stabilizer

2.80

UV-9

0.60

0.80

0.60

SiO 2

0.40

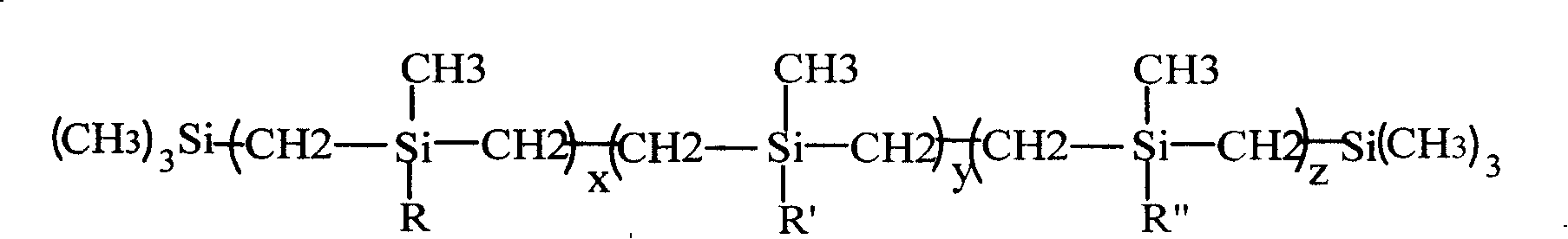

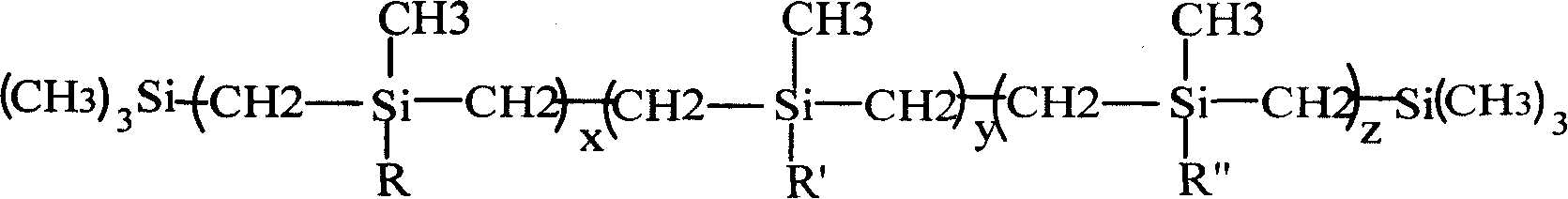

Silicone anti-fog agent

0.85

Compound No Drops

3.50

Phthalocyanine blue BGS

0.01

[0044] 1. Preparation of compound no-drops:

[0045] (1), Sorbitan Sesquiester Stearate

[0046] Put 600kg of stearic acid, 400kg of sorbitol (100% purity) and 15kg of caustic soda into the reaction kettle, continue to heat and stir for esterification after the materials are melted, keep the vacuum degree below -0.5MPa, and keep the reaction temperature at 210-220℃ In the range of ℃, the reaction time is generally about 9 hours. Measure acid value 8mg KOH / g, have added 20kg sulfuric acid (...

Embodiment 2

[0060] Form 2

[0061] raw material name

Raw material weight: kg

pvc

100.00

DOP

40.00

DOA

8.00

3.00

Barium cadmium zinc composite stabilizer

3.50

UV-531

0.60

CA

0.40

1.20

SiO 2

1.00

Silicone anti-fog agent

0.50

Compound No Drops

3.00

Permanent Violet RL

0.02

[0062] 1. Preparation of compound no-drops:

[0063] The preparation method is the same as that in Example 1, and the compound non-drop preparation is ready for use.

[0064] Two, the preparation of the product of the present invention uses the formula raw material in above-mentioned form 2, at first SG3 type PVC resin is 60 orders through screening process vibrating screen screening vibrating screen; In grinding process DOP, DOA, epoxy soybean oil, UV-531, CA, phosphite, and white carbon black are gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com