Method for operating fuel cell, and electric-power generating device

A fuel cell and operating method technology, applied to fuel cell parts, fuel cells, fuel cell additives, etc., capable of solving problems such as fuel cell power generation performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0214] Operation 1-1

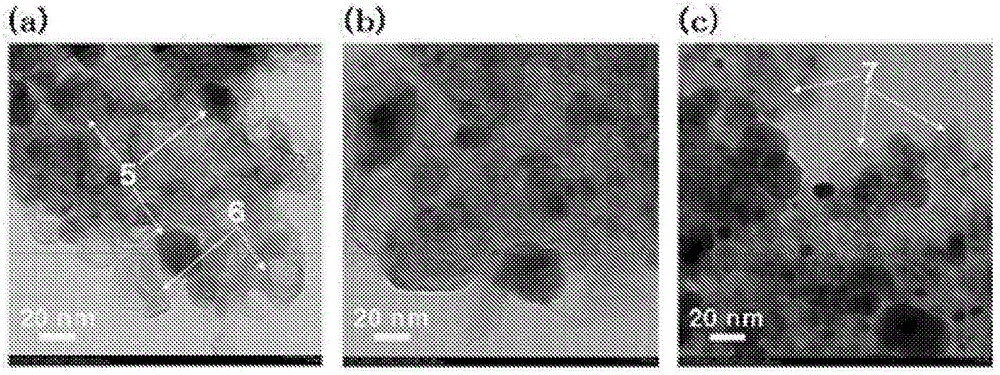

[0215] 5 mL of titanium tetraisopropoxide and 5 mL of acetylacetone were added to a solution of 15 mL of ethanol and 5 mL of acetic acid, and stirred at room temperature to prepare a titanium-containing mixture solution. Separately, 3.76 g of glycine and 0.31 g of iron(II) acetate were added to 20 mL of pure water, and stirred at room temperature to dissolve completely, thereby preparing a glycine-containing mixture solution. Slowly add the titanium-containing mixture solution into the glycine-containing mixture solution to obtain a transparent catalyst precursor solution. Using a rotary evaporator, the temperature of the water bath was set at about 80° C., and the solvent was slowly evaporated while heating and stirring the catalyst precursor solution. The solid residue obtained by completely evaporating the solvent was pulverized finely and uniformly with a mortar to obtain a powder (1a).

[0216] This powder (1a) was placed in a tubular furnace, a...

manufacture example 2、3

[0223] Except changing the amount of distilled water, catalyzer (1), sodium carbonate, chloroplatinic acid hexahydrate and 37% formaldehyde solution as shown in table 1, carried out the operation identical with manufacture example 1, obtains platinum content as table 1 Such different composite catalysts (2), (3).

[0224] In Production Examples 4 to 22, the operations described below and in Table 2 were performed to obtain composite catalysts (4) to (22) each containing 20% by mass of platinum.

manufacture example 4

[0226] Operation 4-1. Modulation of composite particles

[0227] The powder (1a) obtained in the process of operation 1-1 of Production Example 1 was prepared again.

[0228] The powder (1a) was put into a tubular furnace, and the furnace was heated at a heating rate of 10°C / min under a mixed gas atmosphere of hydrogen and nitrogen containing 4% by volume of hydrogen, which was introduced without passing through a bubbler containing distilled water. The internal temperature was raised to 900°C, and heat treatment was performed at 900°C for 1 hour. The heat-treated powder was naturally cooled to room temperature, pulverized in isopropanol with a planetary ball mill, filtered and dried to obtain powder (4b).

[0229] Operation 4-2. Hydrogen peroxide treatment

[0230] Except having changed the powder (1b) into 1.6g of powder (4b), it carried out similarly to operation 1-2 of manufacture example 1, and obtained the powder (henceforth "catalyst (4)").

[0231] Operation 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com