Heat pump system for humidity removing and drying

A technology of heat pump system and hot air system, which is applied in the direction of heat pump, drying, dryer, etc., which can solve the problems of low drying temperature, inability to dehumidify materials at low temperature, and large process differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

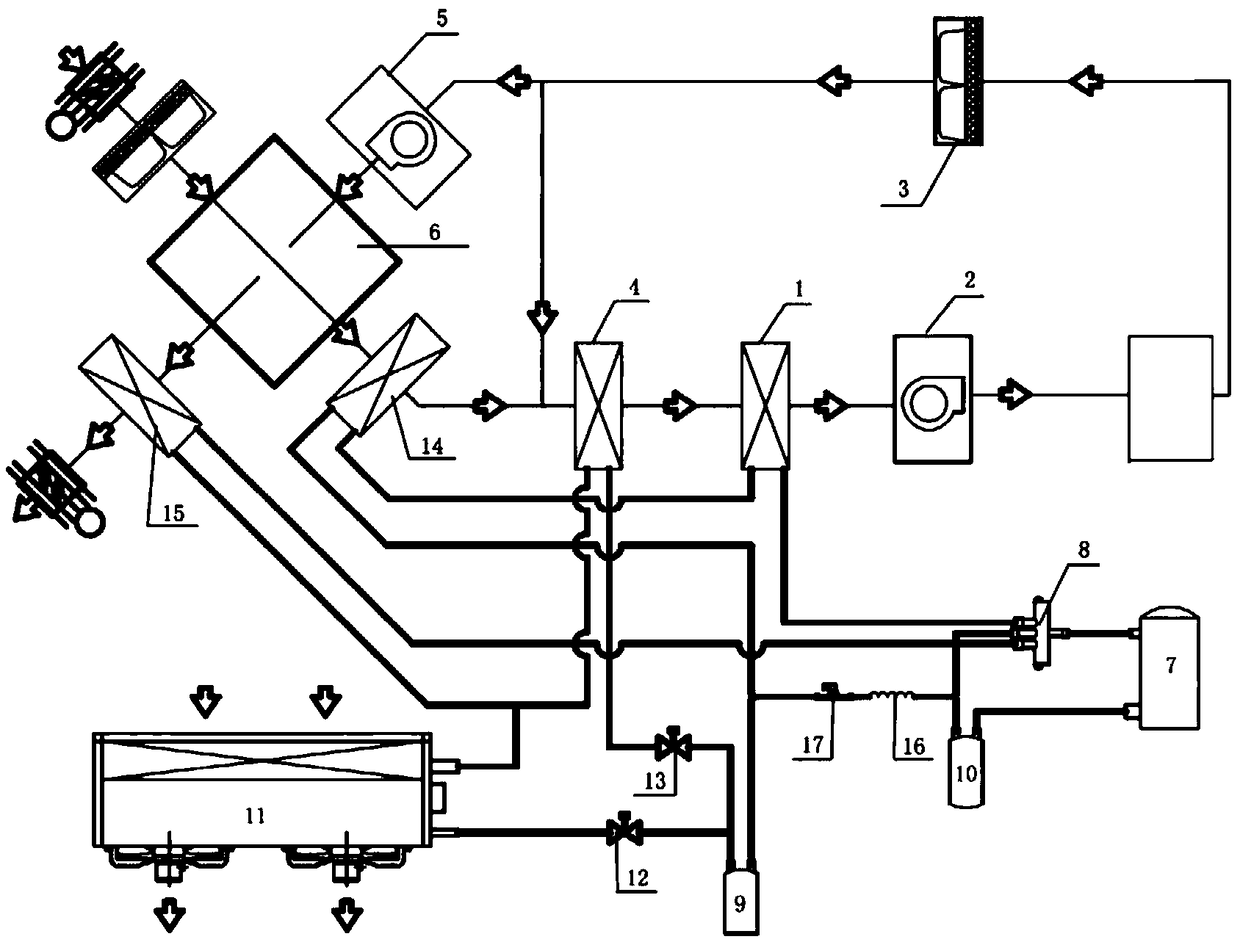

[0144] The structure of this embodiment is as follows: the refrigerant sequentially passes through the compressor-four-way valve-supply air heating condenser-liquid receiver-return air evaporator-four-way valve-vapor-liquid separator-compressor to form a closed refrigeration cycle system The internal refrigerant circulation loop, the hot air discharged through the air outlet of the air supply heating condenser forms the hot air for drying, which is sent into the drying room through the air supply fan; the dried hot air passes through the air outlet of the drying room After being discharged to the first primary filter for filtration, it is then transported to the air inlet of the return air evaporator, through the heat absorption of the return air evaporator, the first dehumidification is completed, and the air after the first dehumidification is sent to the supply air Heating is carried out in the heating condenser to form the first weighting of the basic hot air based on the p...

Embodiment 2

[0146] In this embodiment, on the basis of the structure in Embodiment 1, a secondary dehumidification system is added, and the secondary dehumidification system is arranged in parallel from the air outlet of the first primary effect filter (3) of the primary dehumidification system to the return air evaporator ( 4) On the pipeline of the air inlet, it is used to form the second weighting of the basic hot air based on the secondary dehumidification,

[0147] With the first weighted cooperation provided by the primary dehumidification system, it can provide separate primary dehumidification, separate secondary dehumidification, primary dehumidification and secondary dehumidification cooperation, and three dehumidification working modes. The separate primary dehumidification is used for low humidity dehumidification requirements; Separate secondary dehumidification is used for high humidity dehumidification needs; the primary dehumidification is coordinated with secondary dehumid...

Embodiment 3

[0158] In this embodiment, on the basis of the structure of Embodiment 2, a heat recovery evaporator (15) is added,

[0159] The heat recovery evaporator (15) is arranged at the second air outlet of the total heat heat exchanger (6). Compared with embodiment 2, this embodiment has more heat recovery evaporators, and the heat recovery evaporators are used to convert The residual air after heat exchange discharged through the second air outlet of the total heat heat exchanger (6) is subjected to heat recovery treatment to reinforce the heating capacity of the primary hot air system; the system after adding a heat recovery evaporator;

[0160] Further, the pipeline structure connected to the refrigerant inlet of the heat recovery evaporator (15) has the following characteristics: the pipeline connected to the refrigerant outlet of the return air evaporator (4) and the refrigerant connected to the outdoor evaporator (11) The pipes at the outlet end are connected in parallel; the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com