Agricultural polychloroethylene shed film composite dripless agent

A polyvinyl chloride, no-drip technology, applied in the field of plastic additives, can solve the problems of poor wetting effect, short non-drip duration, affecting the service life of polyvinyl chloride shed film, etc., so as to promote crop growth and improve Light transmittance, beneficial to photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

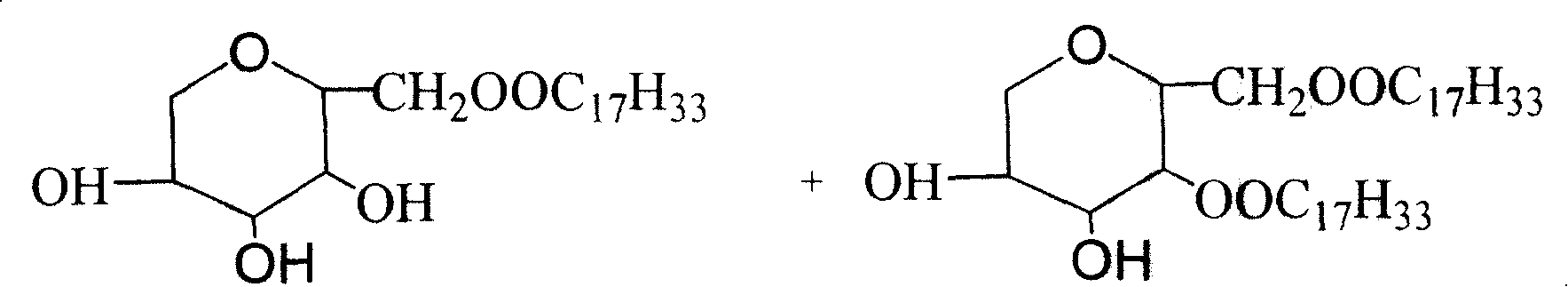

[0031] (1), preparation of sorbitan sesquiester stearate

[0032] Put 600kg of stearic acid, 400kg of sorbitol with a purity of 100% and 15kg of caustic soda into the reaction kettle. After the materials are melted, continue to heat and stir to carry out the esterification reaction. Keep the vacuum degree below -0.5MPa and the reaction temperature at 210-220℃ In the range of ℃, the reaction time is about 9 hours. Measure acid value 8mgKOH / g, add the sulfuric acid (concentration is 70%) of 20kg afterwards and be incubated 2 hours and generate sorbitan stearate sesquiester, its molecular structure is as follows:

[0033]

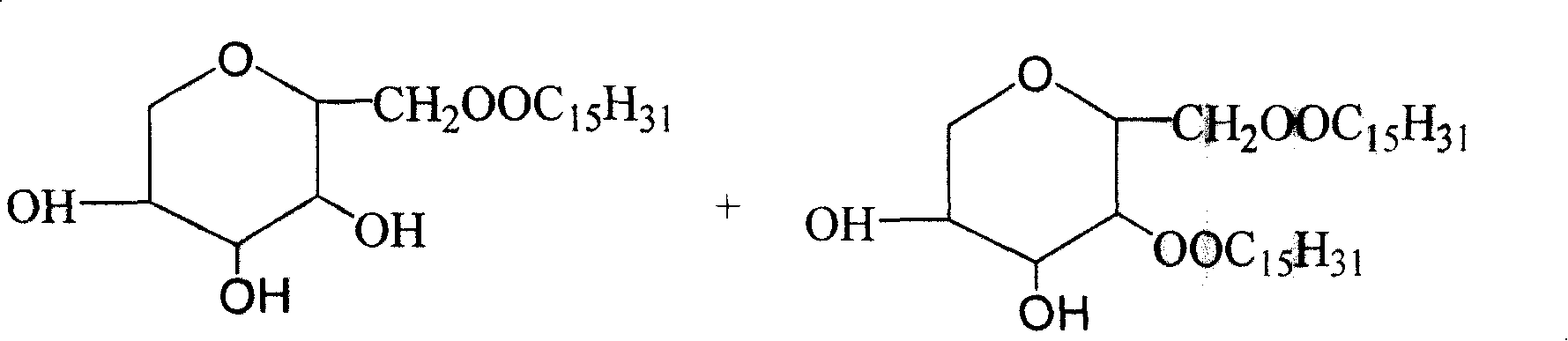

[0034] (2), preparation of sorbitan palmitate sesquiester

[0035] 550kg palmitic acid and 450kg purity are 100% sorbitol and 18kg caustic soda drop in reactor, continue to heat and stir after material melting and carry out esterification reaction, reaction process condition and sorbitan stearyl in above-mentioned (1) The reaction conditions for acid sesq...

Embodiment 2

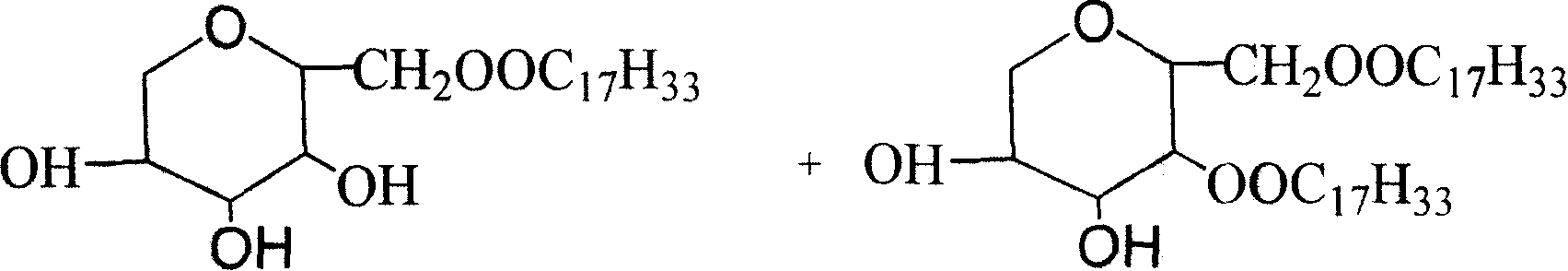

[0044] (1), preparation of sorbitan sesquiester stearate

[0045] Put 620kg of stearic acid, 380kg of sorbitol with a purity of 100% and 34kg of caustic soda into the reaction kettle. After the materials are melted, continue to heat and stir to carry out the esterification reaction, keep the vacuum degree below -0.5MPa, and keep the reaction temperature in the range of 180-200°C Within, the reaction time is about 12 hours. Measure acid value 6mgKOH / g, added the phosphoric acid (concentration is 70%) of 32kg afterwards and incubated 2 hours, generate sorbitan stearate sesquiester, its molecular structure is as follows:

[0046]

[0047] (2), preparation of sorbitan palmitate sesquiester

[0048] 570kg palmitic acid and 430kg purity are 100% sorbitol and 30kg caustic soda and drop into reactor, continue to heat and stir after material melting and carry out esterification reaction, reaction technology and above-mentioned sorbitan stearate sesquiester The reaction conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com