Efficient water injection method and device of hydraulic fracture permeability increase auxiliary coal seam

A hydraulic fracturing and water injection equipment technology, applied in mining equipment, earthwork drilling, safety devices, etc., can solve the problems of poor permeability and difficult water injection, so as to improve air permeability, reduce engineering quantity, and improve water injection work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

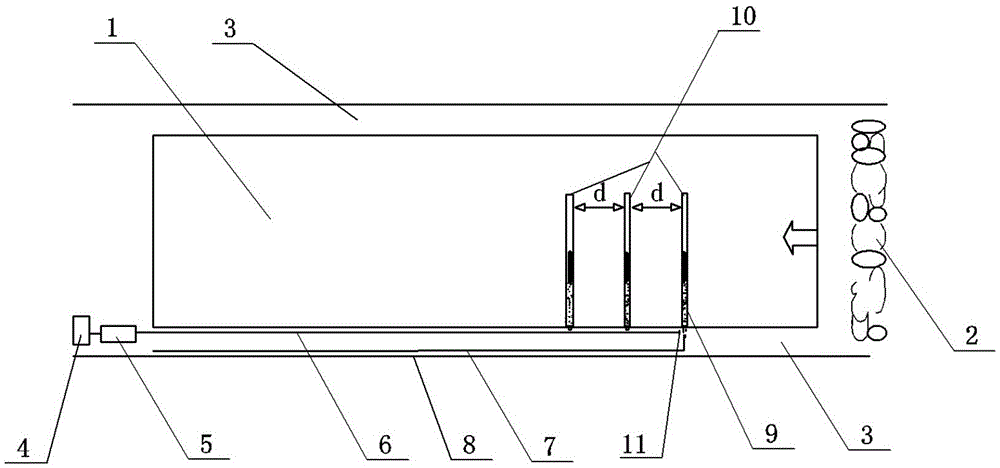

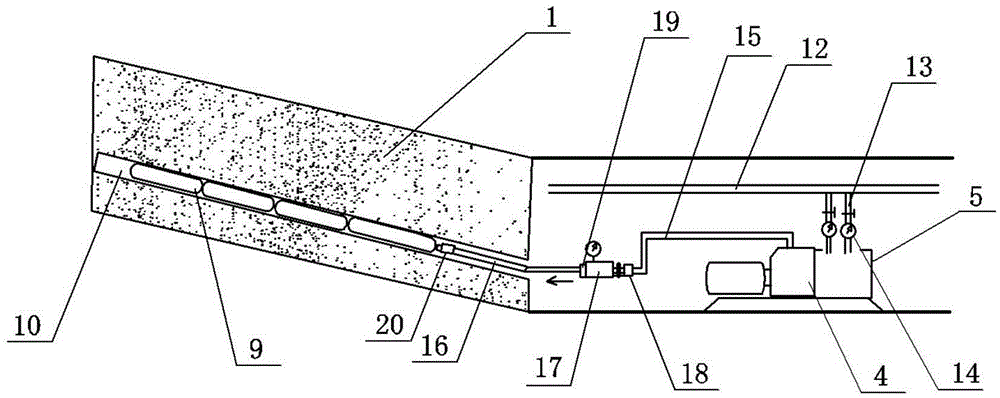

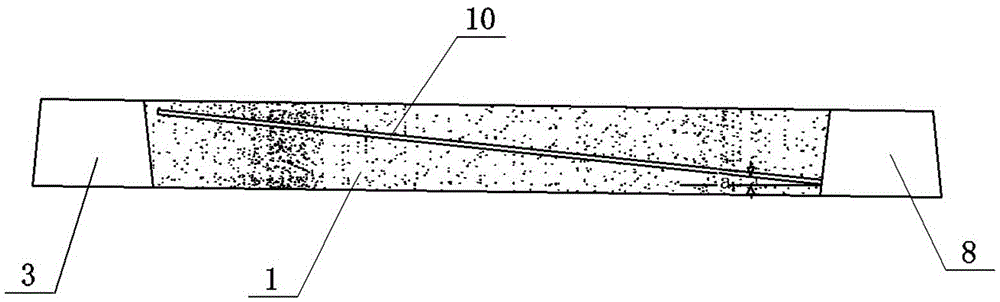

[0028] Example 1: A hydraulic fracturing anti-permeability auxiliary coal seam efficient water injection method, the overall design concept of this example is as follows: figure 1 As shown, before the coal seam static pressure water injection, the high-pressure water generated by the emulsion pump is connected to the drilled static pressure water injection borehole through the high-pressure pipeline, and the water wedge generated by the high-pressure water is used to cut the coal seam around the borehole. The splitting effect, the high-pressure water injected into the cracks of the coal body (the original cracks and the cracks that appeared after fracturing) overcomes the minimum principal stress and the anti-cracking pressure of the coal body, making the cracks widen, stretch and communicate, increasing the coal seam through the cracks. The number and the opening degree of a single fracture surface will be increased, and more artificial fractures and fissures will be generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com